Degradable trace cutting oil and preparation method thereof

A cutting oil and micro-quantity technology, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problems of poor degradation and achieve strong wear reduction, good lubricity, and good wear reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

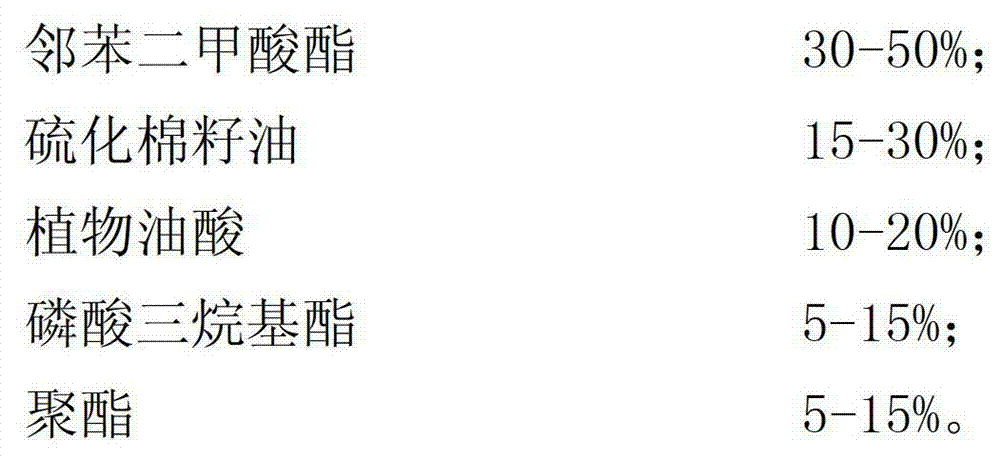

[0028] Stir 400 grams of phthalates, 250 grams of vulcanized cottonseed oil, 150 grams of vegetable oleic acid, 100 grams of trialkyl phosphate, and 100 grams of polyester, stir and heat to 60 ° C, keep constant temperature and fully stir for 60 minutes, and cool naturally After packing. Using the prepared degradable micro cutting oil in a micro cutting lubricating device can save more than 90% of the cutting oil / fluid usage.

Embodiment 2

[0030] Stir 360 grams of phthalates, 260 grams of vulcanized cottonseed oil, 160 grams of vegetable oleic acid, 110 grams of trialkyl phosphate, and 110 grams of polyester, stir and heat to 60 ° C, keep constant temperature and fully stir for 60 minutes, and cool naturally After packing. Using the prepared degradable micro cutting oil in a micro cutting lubricating device can save more than 90% of the cutting oil / fluid usage.

Embodiment 3

[0032] Stir 420 grams of phthalates, 240 grams of vulcanized cottonseed oil, 150 grams of vegetable oleic acid, 100 grams of trialkyl phosphate, and 90 grams of polyester, stir and heat to 60 ° C, keep constant temperature and fully stir for 60 minutes, and cool naturally After packing. Using the prepared degradable micro cutting oil in a micro cutting lubricating device can save more than 90% of the cutting oil / fluid usage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com