Preparation method of 1,1,1,3-tetrafluoropropene

A technology of tetrafluoropropene and tetrachloropropene, which is applied in 1 field, can solve the problems of complex process, poor economy, difficulty in obtaining HCFC-1233zd and HFC-245fa, etc., and achieve the effect of simple process route and easy price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

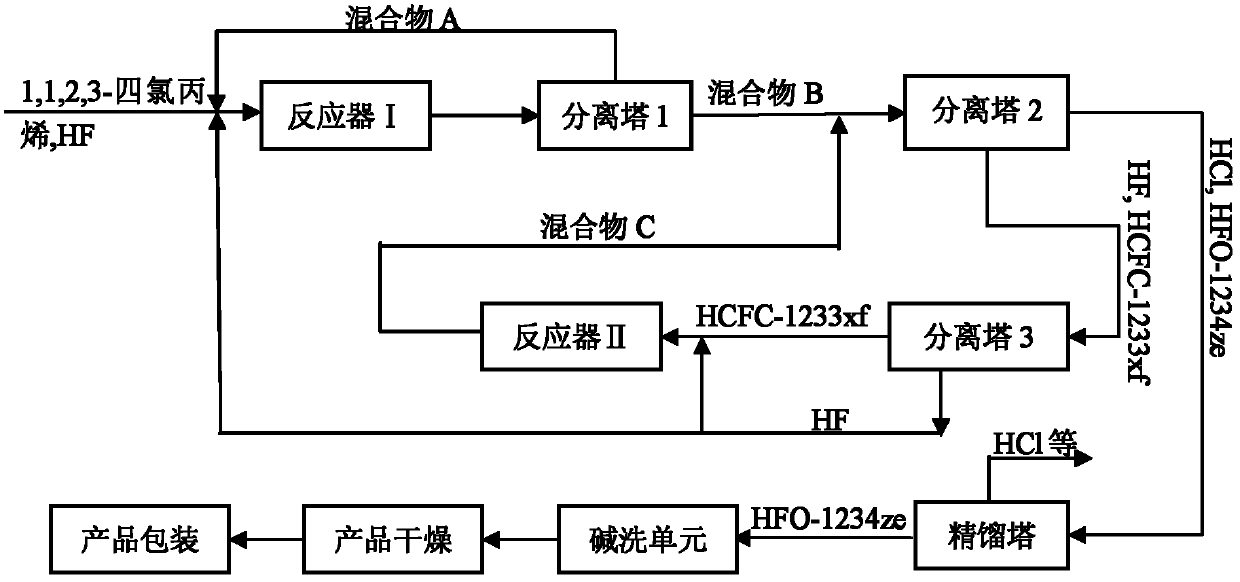

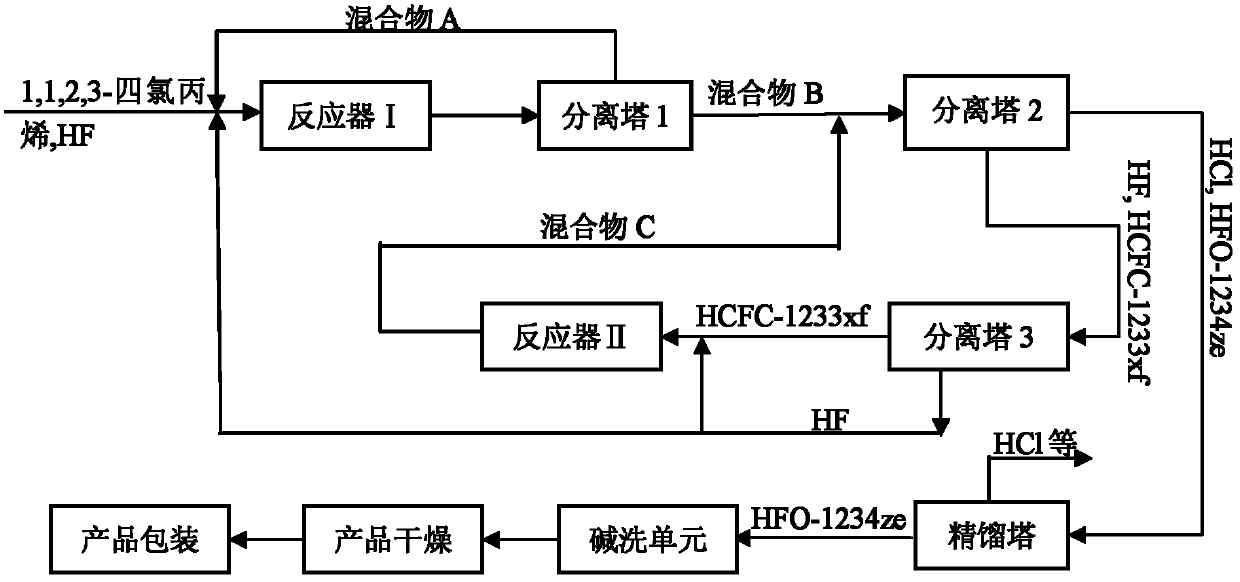

Method used

Image

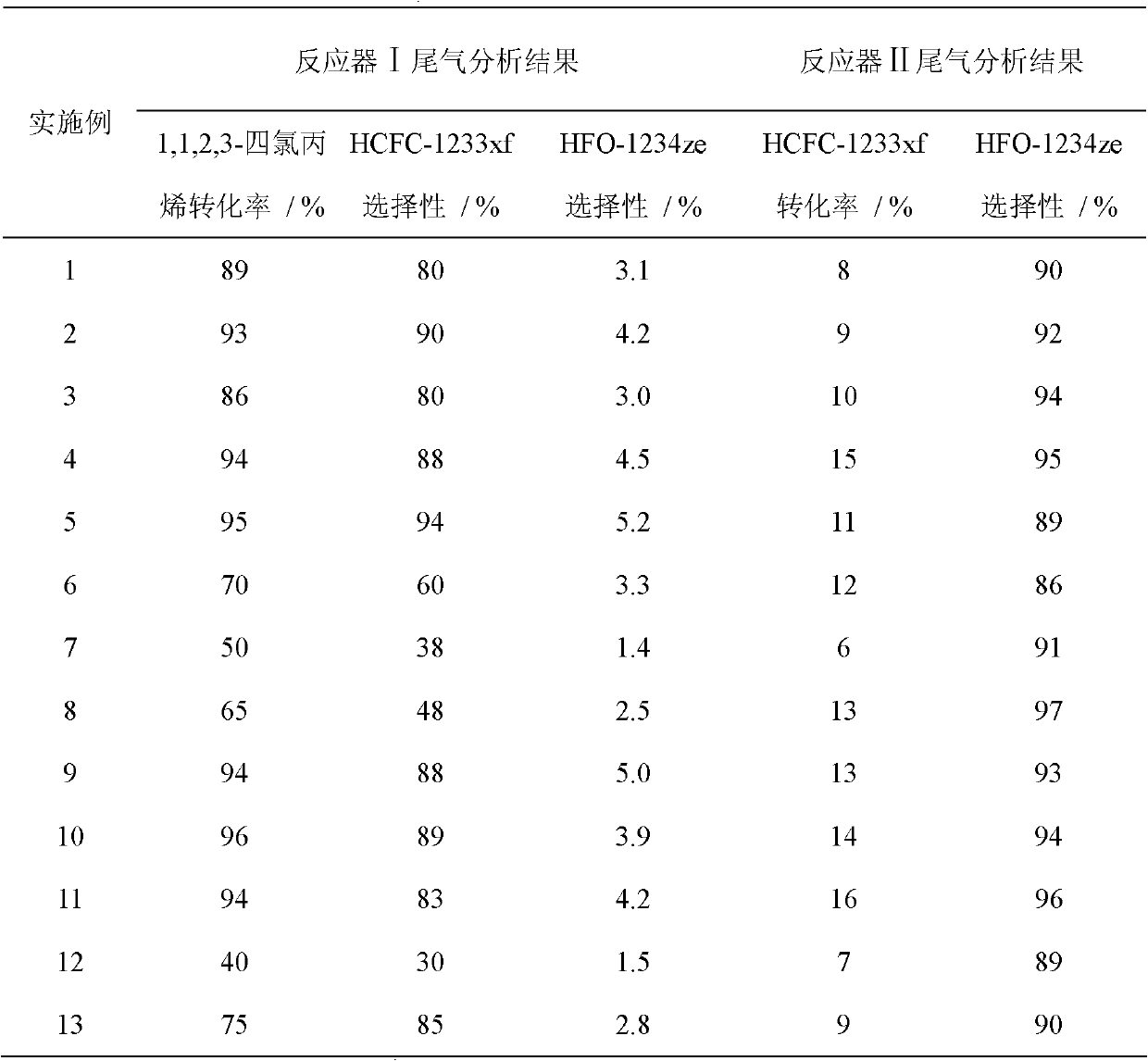

Examples

Embodiment 1

[0033] Catalyst A preparation. First, weigh Al according to the molar ratio of Cr to Al of 9:1 2 o 3 ·H 2 O and Cr(NO 3 ) 3 9H 2 O, mix evenly with an appropriate amount of water, add a certain amount of ammonium carbonate until the precipitation is complete, then separate and wash until the filtrate is neutral, and then dry the precipitate at 120°C. Shape the dried precipitate at 500°C, N 2 Calcined in the atmosphere for 10 hours to obtain a catalyst precursor; the catalyst precursor was treated with HF at 350° C. for 5 hours to obtain catalyst A.

[0034] Catalyst B, according to AlF 3 Loading capacity 1% (activated carbon mass fraction), weigh Al(NO 3 ) 3 9H 2 O and activated carbon, mixed with appropriate amount of water, dried at 400°C N 2 Roasting in the atmosphere for 5 hours; then according to the Pd loading 0.2% (activated carbon mass fraction), measure H 2 PdCl 4 The solution was mixed with the above-mentioned calcined product, impregnated overnight, and...

Embodiment 2

[0038] Catalyst A preparation. First, weigh Al according to the molar ratio of Cr to Al of 8:2 2 o 3 ·H 2 O and Cr(NO 3 ) 3 9H 2 O, mix evenly with an appropriate amount of water, add a certain amount of ammonium carbonate until the precipitation is complete, then separate and wash until the filtrate is neutral, and then dry the precipitate at 120°C. The dried precipitate was shaped and calcined at 500°C in N2 atmosphere for 10 hours to obtain a catalyst precursor; the catalyst precursor was treated with HF at 350°C for 5 hours to obtain catalyst A.

[0039] Catalyst B, according to AlF 3 Loading capacity 1% (activated carbon mass fraction), weigh Al(NO 3 ) 3 9H 2 O and activated carbon, mixed with appropriate amount of water, dried at 400°C N 2 Roasting in the atmosphere for 5 hours; then according to the Pd loading 0.2% (activated carbon mass fraction), measure H 2 PdCl 4 The solution was mixed with the above-mentioned calcined product, impregnated overnight, and...

Embodiment 3

[0043] Catalyst A preparation. First, weigh Al according to the molar ratio of Cr to Al of 7:3 2 o 3 ·H 2 O and Cr(NO 3 ) 3 9H 2 O, mix evenly with an appropriate amount of water, add a certain amount of ammonium carbonate until the precipitation is complete, then separate and wash until the filtrate is neutral, and then dry the precipitate at 120°C. Shape the dried precipitate at 500°C, N 2 Calcined in the atmosphere for 10 hours to obtain a catalyst precursor; the catalyst precursor was treated with HF at 350° C. for 5 hours to obtain catalyst A.

[0044] Catalyst B, according to AlF 3 Loading capacity 1% (activated carbon mass fraction), weigh Al(NO 3 ) 3 9H 2 O and activated carbon, mixed with appropriate amount of water, dried at 400°C N 2 Roasting in the atmosphere for 5 hours; then according to the Pd loading 0.5% (activated carbon mass fraction), measure the H 2 PdCl 4 The solution was mixed with the above-mentioned calcined product, impregnated overnight,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com