Process method for producing aluminum hydroxide by seed decomposition of supersaturated sodium aluminate solution

A technology of aluminum hydroxide and process method, which is applied in the field of metallurgy, can solve the problems of reducing the supersaturation of sodium aluminate solution, bulky decomposition tank, and large power consumption, so as to improve output rate and product quality, and change kinetics Conditions, the effect of prolonging the cleaning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

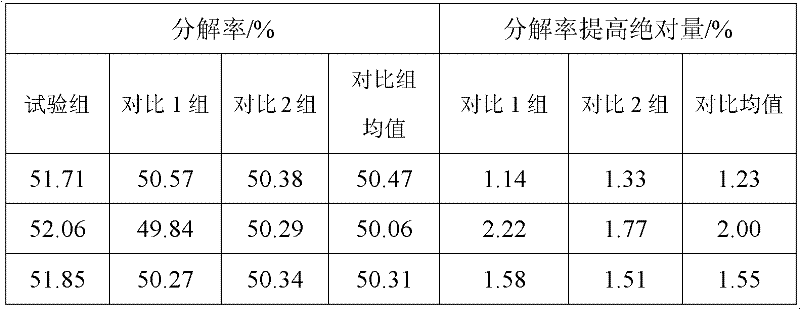

Embodiment 1

[0033] Example 1. The cylindrical-flat bottom structure is used to mechanically stir the seed tanks, each seed tank has a diameter of 14m, a height of 35m, and a tank volume of 4500m 3 . A layer of rotating paddles is used for local agitation at the bottom area (or discharge end) of each seed sub-trough. The agitation intensity is determined by the fact that the aluminum hydroxide particles at the bottom of the seed crystal decomposition tank can remain suspended and not generated at the bottom of the seed crystal decomposition tank. The deposition shall prevail, and the rest shall be carried out according to the requirements of the daily production operation procedures of the alumina plant. The feeding speed at the discharge end of the sub-groove is greater than the final speed of the interference settling of solid particles in the solution. The way of material lifting can be but not limited to compressed air, mechanical pump or manufacturing liquid level difference and oth...

Embodiment 2

[0034] Example 2. The air-stirred seed tank with cylindrical-conical bottom structure is adopted. The diameter of each seed tank is 8.2m, the height is 29.7m, and the tank volume is 1300m 3 . Blow compressed air into the bottom area (or discharge end) of each seed sub-tank for local agitation. The agitation intensity is based on the fact that the aluminum hydroxide particles at the bottom of the seed crystal decomposition tank can maintain a suspended state and no deposition occurs at the bottom of the seed crystal decomposition tank. The rest shall be carried out according to the requirements of the daily production operation procedures of the alumina plant. The feeding speed at the discharge end of the sub-groove is greater than the final speed of the interference settling of solid particles in the solution. The way of material lifting can be but not limited to compressed air, mechanical pump or manufacturing liquid level difference and other ways.

Embodiment 3

[0035] Example 3. Adopt cylinder-multi-cone bottom combined air stirring seed tank, each seed tank has a diameter of 15m, a height of 35m, and a tank volume of 5500m 3 ;Blow compressed air into each cone bottom (or discharge end) of the bottom area of each seed sub-trough for partial agitation. The agitation intensity is such that the aluminum hydroxide particles at the bottom of the seed crystal decomposition tank can maintain a suspended state and not decompose in the seed crystal The deposition at the bottom of the tank shall prevail, and the rest shall be carried out in accordance with the requirements of the daily production operation procedures of the alumina plant. The feeding speed at the discharge end of the sub-groove is greater than the final speed of the interference settling of solid particles in the solution. The way of material lifting can be but not limited to compressed air, mechanical pump or manufacturing liquid level difference and other ways.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com