Nitrogen-doped porous carbon material and preparation method thereof

A nitrogen-doped porous carbon and Lewis acid technology, which is applied in the preparation/purification of carbon, chemical instruments and methods, electrolytic capacitors, etc., can solve the problems of expensive equipment, small sample volume, high production cost, etc., and achieve abundant raw material resources , Strong reproductive ability, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 2mg of Bacillus subtilis and inoculate it into 50mL of culture medium, cultivate it with shaking at 36°C until the cell growth enters the logarithmic phase, collect the bacteria by centrifugation, and freeze-dry them for later use; the formula of the culture medium is: 1L distilled water, 20g glucose, 15g Peptone, 5g sodium chloride and 0.5g beef extract.

[0029] After mixing the lyophilized Bacillus subtilis cells and zinc chloride at a mass ratio of 1:4, transfer them to a high-temperature furnace, and treat them at 800°C for 4 hours under the protection of nitrogen, and wash them with 0.1M dilute hydrochloric acid solution to pH after cooling. The value is 6-7, and it can be obtained after drying.

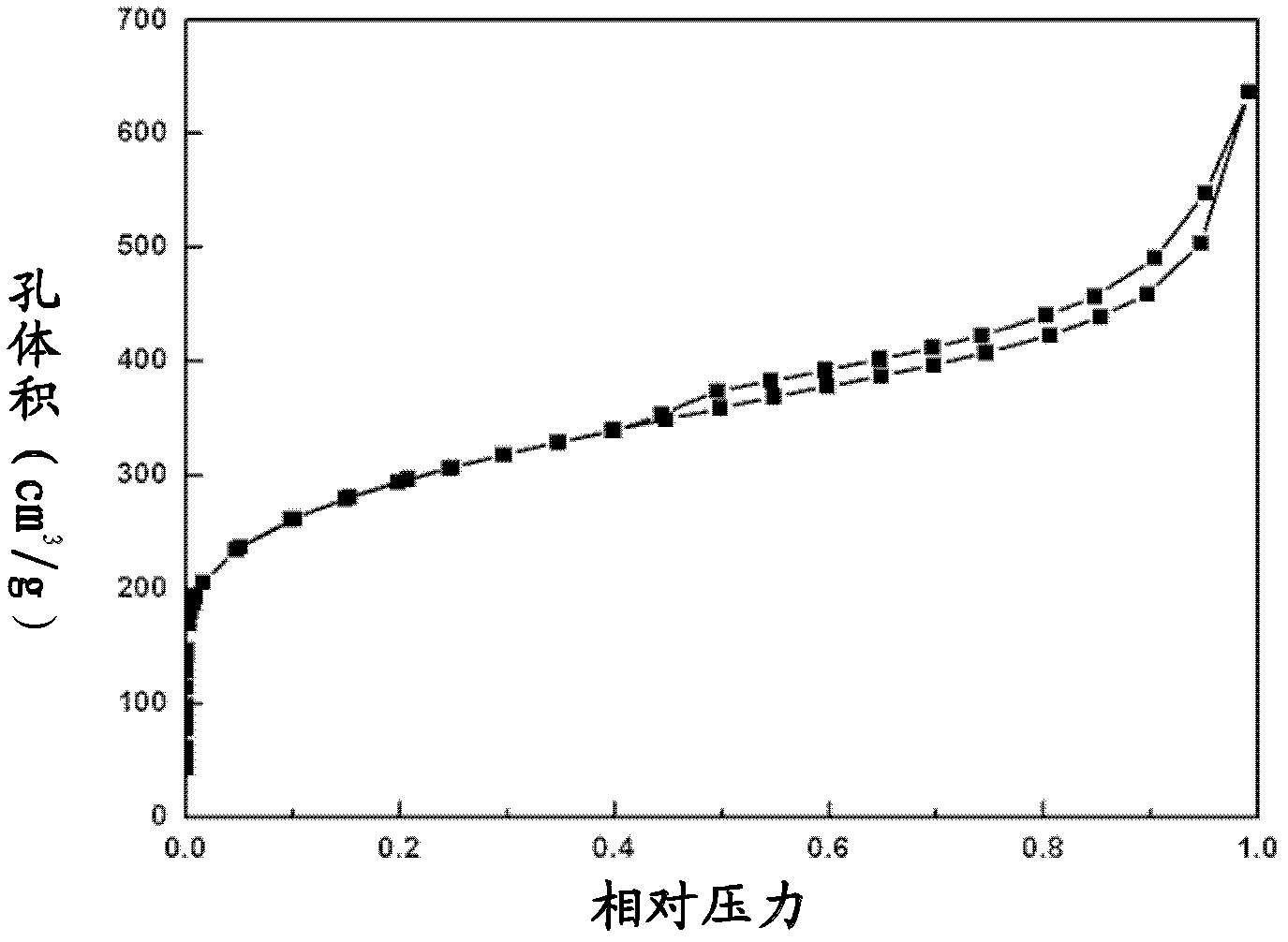

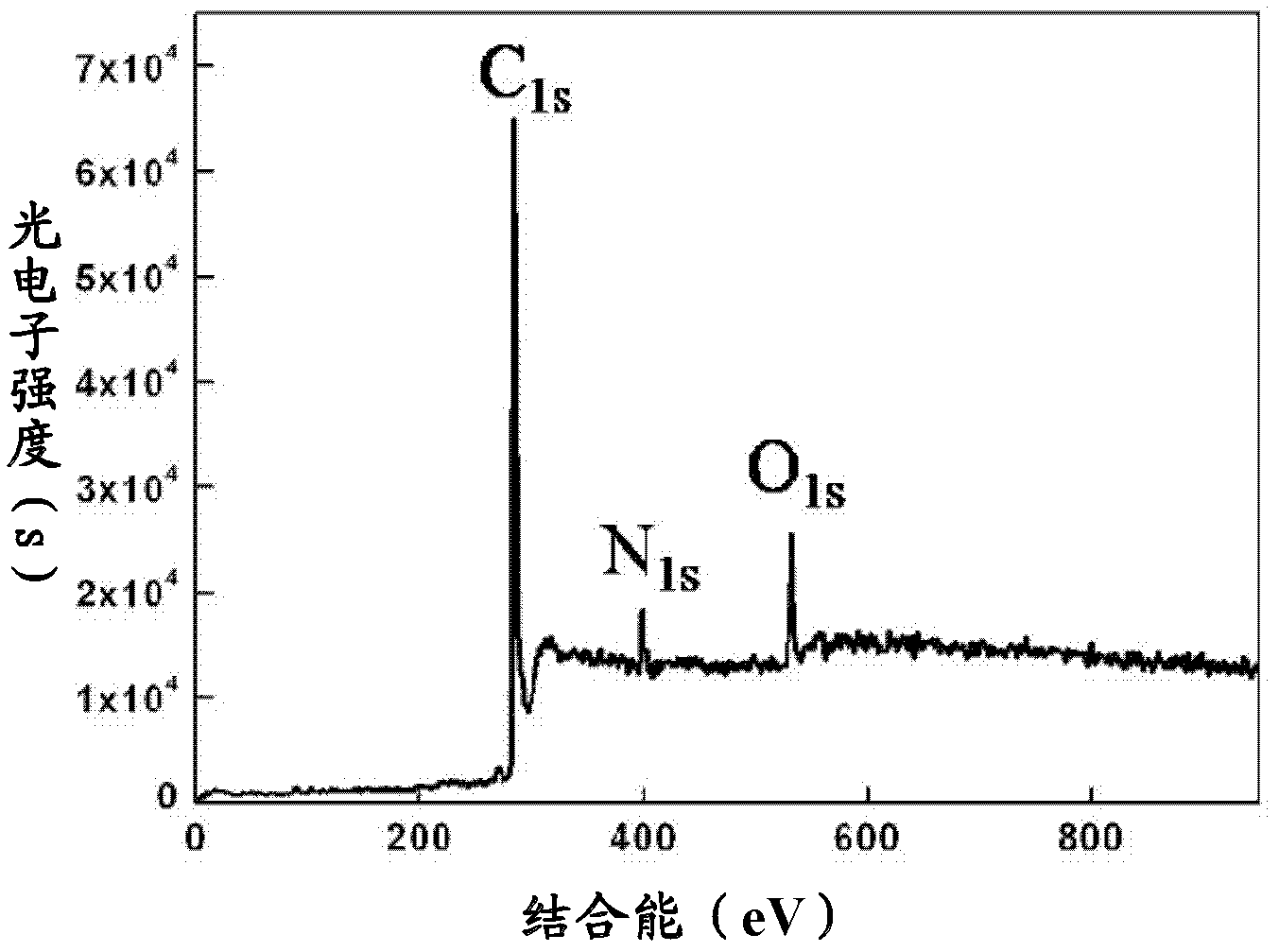

[0030] The physical and chemical properties of the obtained nitrogen-doped porous carbon material were characterized by scanning electron microscopy, elemental analyzer, etc. See figure 1 and figure 2 , the oxygen reduction electrocatalysis test and supercapacit...

Embodiment 2

[0033] Weigh 2mg of Bacillus subtilis and inoculate it into 50mL of culture medium, cultivate it with shaking at 36°C until the cell growth enters the logarithmic phase, collect the bacteria by centrifugation, and freeze-dry them for later use; the formula of the culture medium is: 1L distilled water, 20g glucose, 15g Peptone, 5g sodium chloride and 0.5g beef extract.

[0034]After mixing the lyophilized Bacillus subtilis and zinc chloride at a mass ratio of 2:1, transfer it to a high-temperature furnace, and treat it at 500°C for 4 hours under the protection of nitrogen, and wash it with 0.1M dilute hydrochloric acid solution to pH after cooling. The value is 6-7, and it can be obtained after drying.

[0035] The specific surface area of nitrogen-doped porous carbon material obtained by nitrogen adsorption and desorption analysis and elemental analyzer is 687m 2 g -1 , the pore size is mainly micropores less than 2nm; elemental analysis mass percent is carbon 78.1%, oxyge...

Embodiment 3

[0037] Weigh 2mg of Bacillus subtilis and inoculate it into 50mL of culture medium, cultivate it with shaking at 36°C until the cell growth enters the logarithmic phase, collect the bacteria by centrifugation, and freeze-dry them for later use; the formula of the culture medium is: 1L distilled water, 20g glucose, 15g Peptone, 5g sodium chloride and 0.5g beef extract.

[0038] After mixing the freeze-dried Bacillus subtilis and zinc chloride at a mass ratio of 1:1, transfer it to a high-temperature furnace, treat it at 800°C for 20 hours under nitrogen protection, and wash it with 0.1M dilute nitric acid solution to pH after cooling. The value is 6-7, and it can be obtained after drying.

[0039] The specific surface area of nitrogen-doped porous carbon material obtained by nitrogen adsorption and desorption analysis and elemental analyzer is 756m 2 g -1 , the pore size is mainly micropores; elemental analysis mass percent is carbon 90.3%, oxygen 4.7%, nitrogen 4.0%. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com