Silicon-based airtight packaging casing

An encapsulation shell and airtightness technology, which is applied in the airtight packaging field of MEMS chips, can solve the problems of high process temperature and high packaging cost, and achieve the effects of simple process, low cost and long cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0020] The present invention adopts monocrystalline silicon as the base and cap material of airtight packaging, which can realize low-cost MEMS chip airtight packaging, and its specific implementation is as follows:

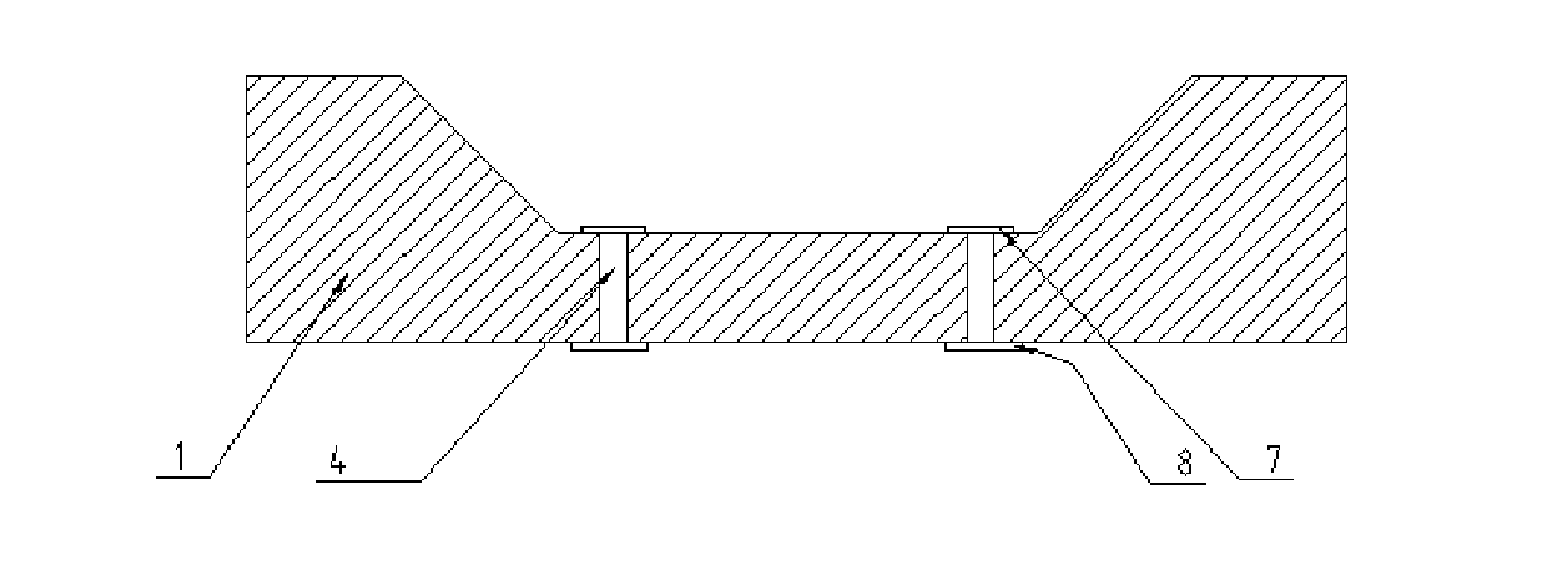

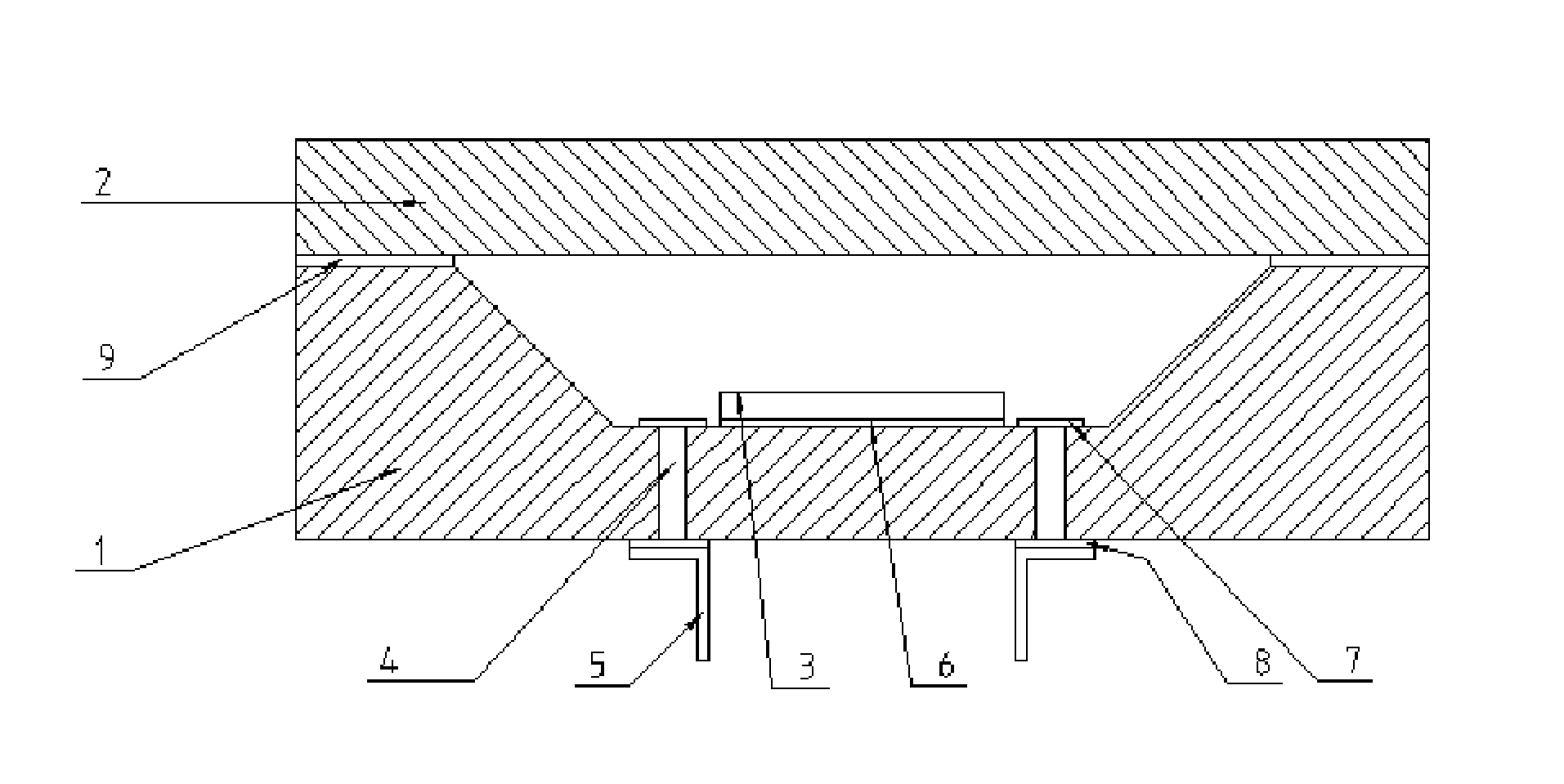

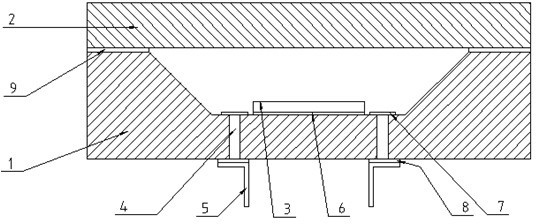

[0021] Such as figure 1 As shown, the stem 1 is a monocrystalline silicon wafer with a groove, and the bottom of the groove has a through hole. The signal channel 4 is formed after the through hole is plated. There are pads at both ends of the signal channel 4, and a pad 7 is made on the side of the groove for wire bonding with the MEMS chip to conduct the signal; at the bottom of the tube base (the side without the groove), a Pad 8.

[0022] The overall thickness of the monocrystalline silicon wafer is between 600 μm and 800 μm; the depth of the groove is between 200 μm and 300 μm. The groove is processed by anisotropic wet etching, and the bottom of the groove is chemically mechanically polished for Stick the chip to be packaged on the tube socket; the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com