Low-emission glass and manufacturing method for low-emission glass

A low-emissivity glass and glass substrate technology, applied in chemical instruments and methods, glass/slag layered products, sputtering coating, etc., can solve problems such as increasing production and transportation costs, achieve good appearance, color, saving Production cost and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

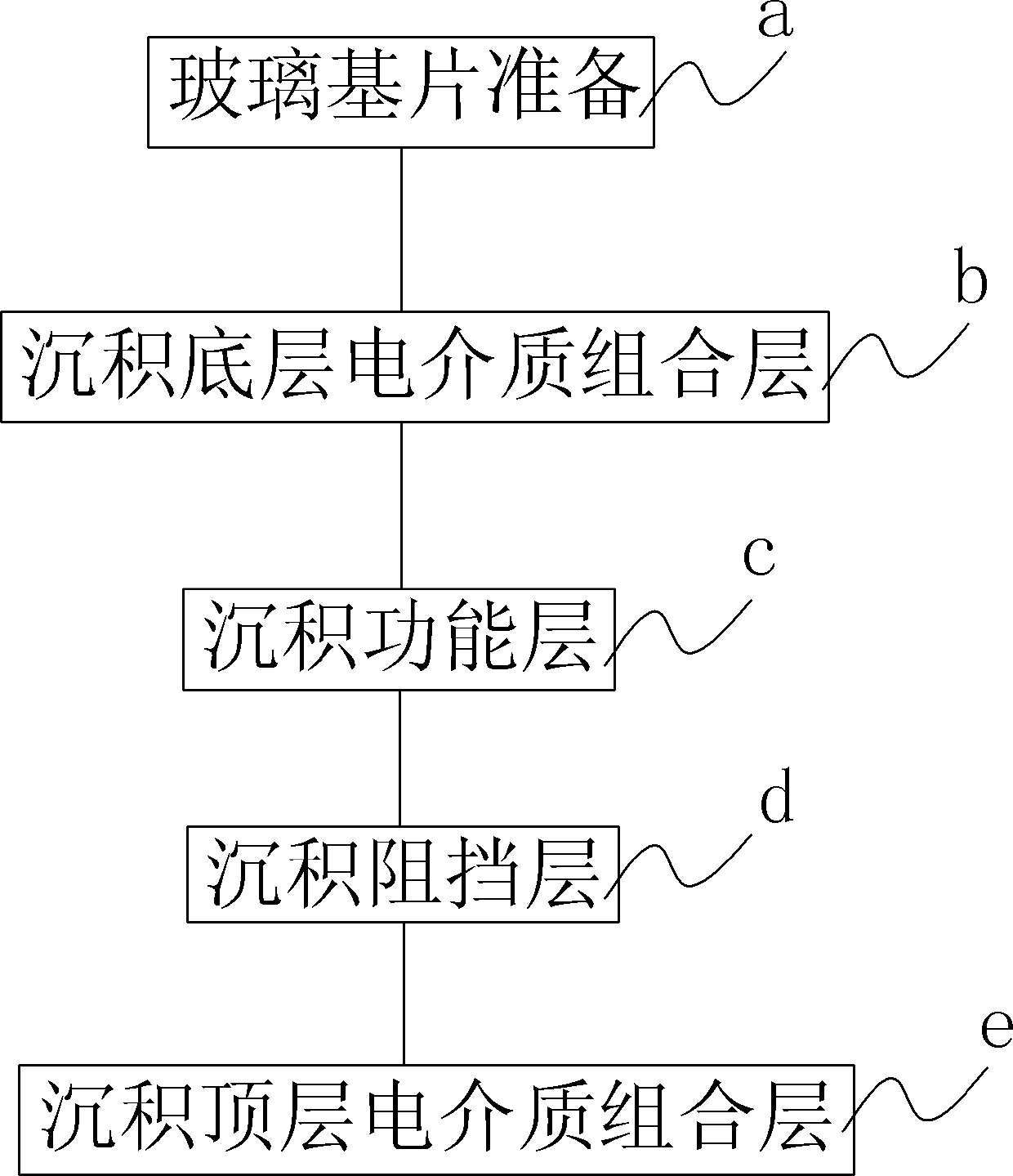

[0035] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

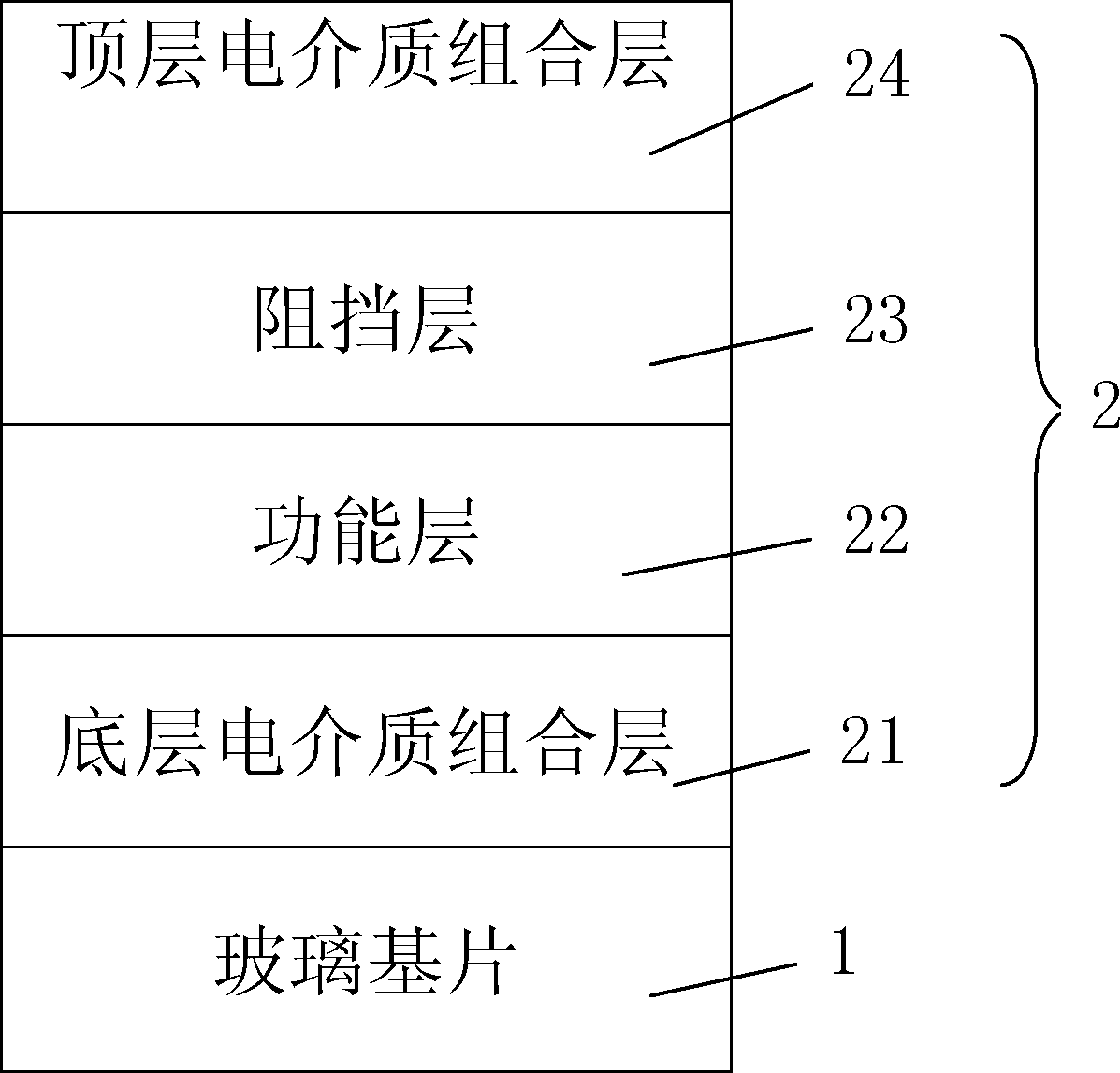

[0036] see figure 1 , figure 1 It is a schematic structural diagram of low-emissivity glass according to an embodiment of the present invention. The low-emissivity glass of the present invention includes a glass substrate 1 and a film layer 2 attached to the glass substrate 1, and the film layer 2 includes an underlying dielectric combination layer 21, a functional layer 22, and a barrier layer 23 stacked in sequence. and the top dielectric composite layer 24 , the bottom dielectric composite layer 21 is attached on the glass substrate 1 .

[0037] In this embodiment, the functional layer 22 is preferably a tungsten-doped aluminum oxide zinc dielectric layer. The tungsten-doped zinc-aluminum oxide dielectric layer preferably adopts a stoichiometric ratio of ZnO / Al 2 o 3 / W=96:2:2 cast target. The thickness of the tungste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com