Locking device used for injection moulding machine

A locking device and mold technology, applied in the field of locking devices, can solve the problems of long distance from the locking device and high cost of the driving unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

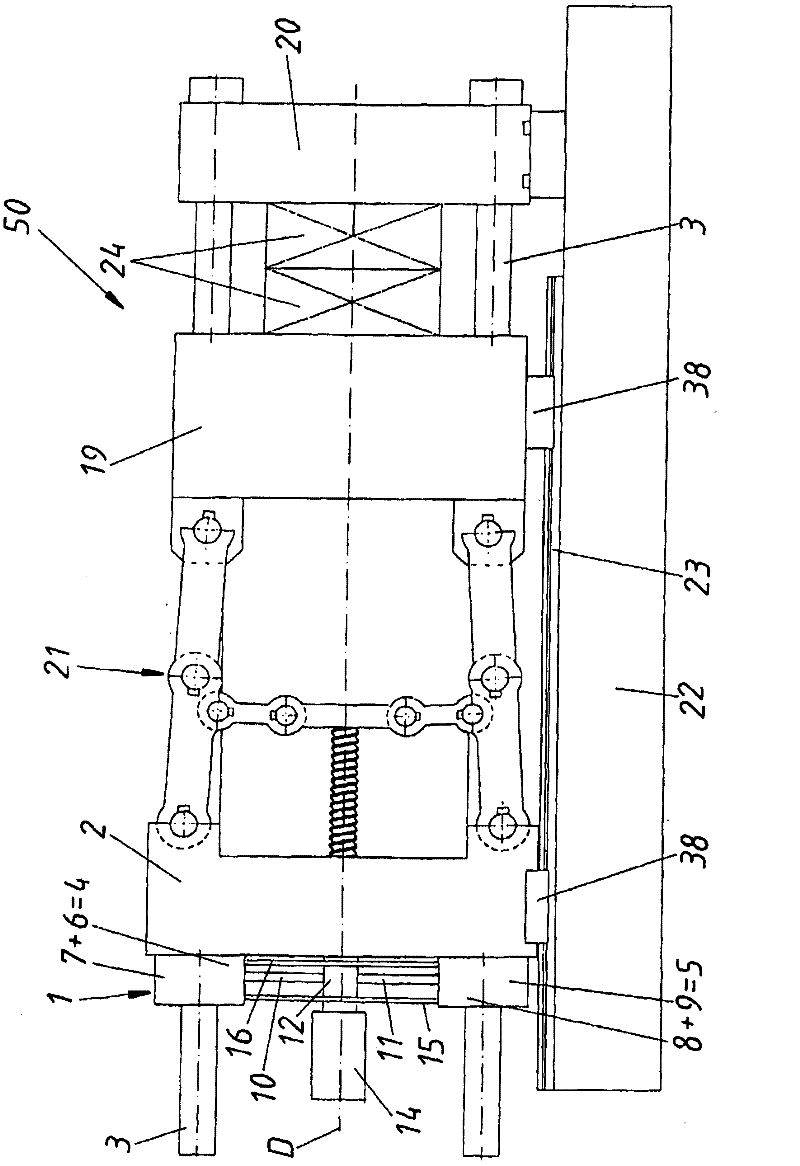

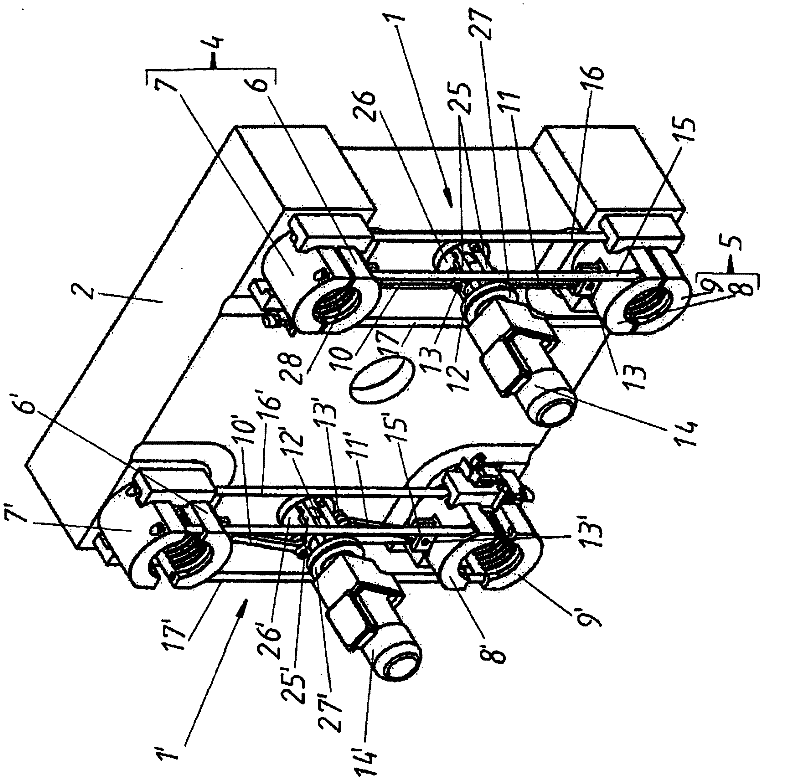

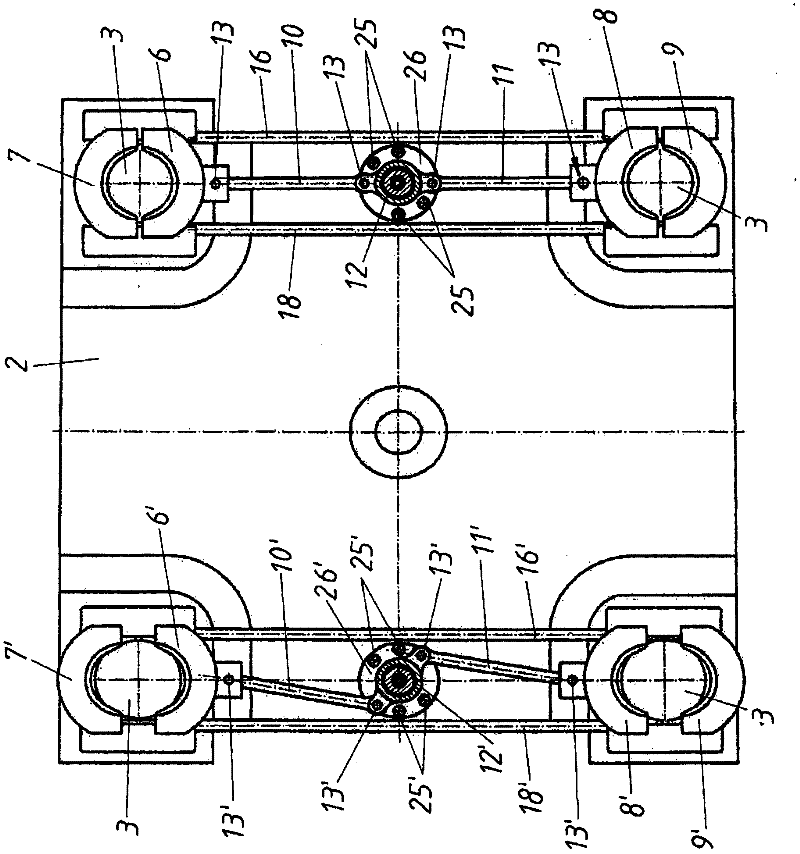

[0024] figure 1 Overall, a view of an injection molding machine 50 is shown, comprising a mold half 24 clamped between a stationary mold clamping plate 20 and a movable mold clamping plate 19 . A crank mechanism 21 is arranged between the movable mold clamping plate 19 and the end plate 2 . The movable mold clamping plate 19 and the end plate 2 are each mounted movably via slides 38 on guide rails 23 of the frame 22 of the injection molding machine 50 . All three plates 2 , 19 and 20 are passed through by a total of four crossbeams 3 , wherein the locking device 1 is shown schematically at the end of the crossbeams 3 on the plate side. This locking device 1 is mounted on the end plate 2 and holds the end plate 2 fixedly on the beam 3 by clamping together the half shells 7 and 6 or 8 and 9 of the clamping elements 4 or 5 . In order to be able to synchronize the two clamping elements 4 and 5, on the one hand the known per se rods 16 and 15 (as well as the connecting rods 17 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com