Method for manufacturing aluminum sheet circle for soft aluminum tube by aluminum rod

A technology of aluminum discs and aluminum rods, applied in metal processing equipment and other directions, can solve the problems of pitting, pinholes, scabs, hair pulling, complicated steps, etc., so as to save the car skin process, change the processing method, and realize automatic production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

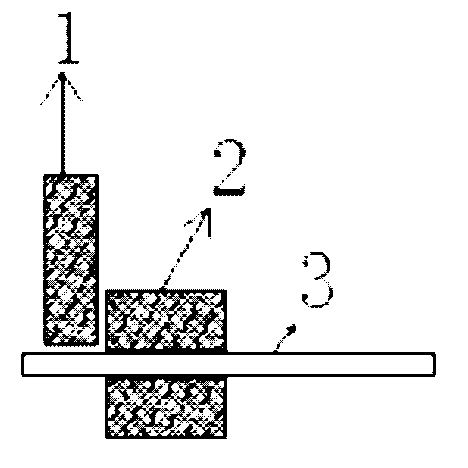

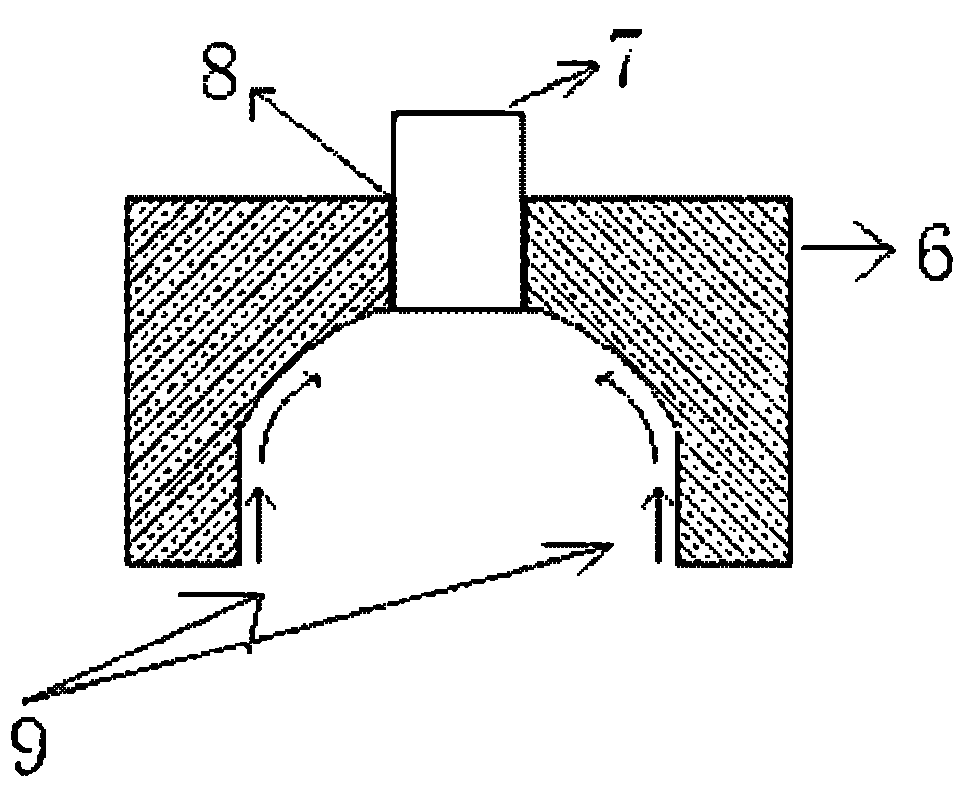

[0044] The present invention is described further in conjunction with accompanying drawing, and the manufacturing technology of this device is very clear to those skilled in the art.

[0045] Concrete production process of the present invention is as Figure 10 shown.

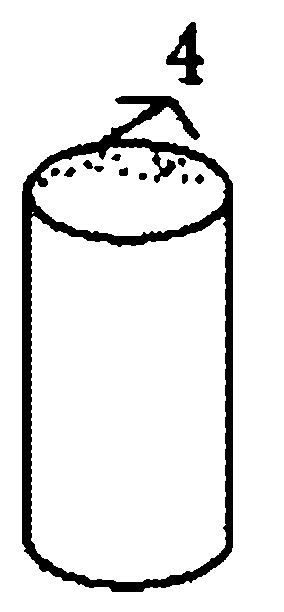

[0046] (1) Raw materials: directly purchase electrical round aluminum rods manufactured by electrolytic aluminum factories that meet the GB / T3954-2001 standard, or aluminum rods produced by other methods with a purity greater than 99.50%. When extruded aluminum rods are used as raw materials, they can be directly imported Directional extrusion process;

[0047] (2) Axial cold deformation: (drawing, drawing) In the production, the aluminum rod is subjected to axial cold deformation by wire drawing or drawing process (generally, the deformation amount is 20%-30%), and the details can be seen in the next process. It depends on the process matching and the smoothness of the surface of the aluminum rod. It can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com