Soldering set for agitating friction welding with adjustable inclined angle and concave-top and convex-bottom type shaft shoulder and method thereof

A friction stir welding and shaft shoulder technology, applied in the field of friction stir welding welding tools, can solve the problems of difficulty in forming the weld, reduced joint performance, excessive heat input, etc., to ensure that the upper surface is formed, well formed, simplified The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

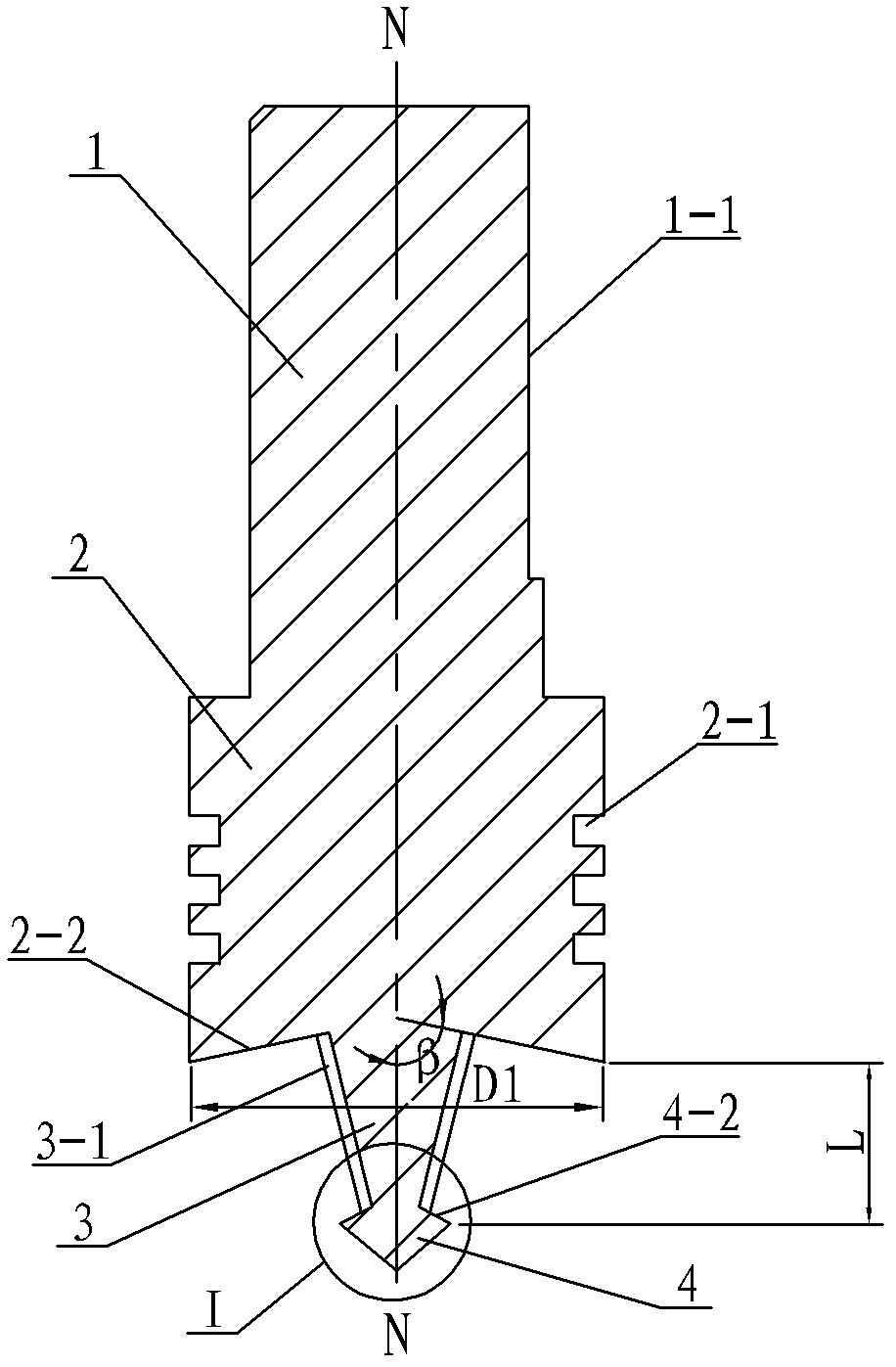

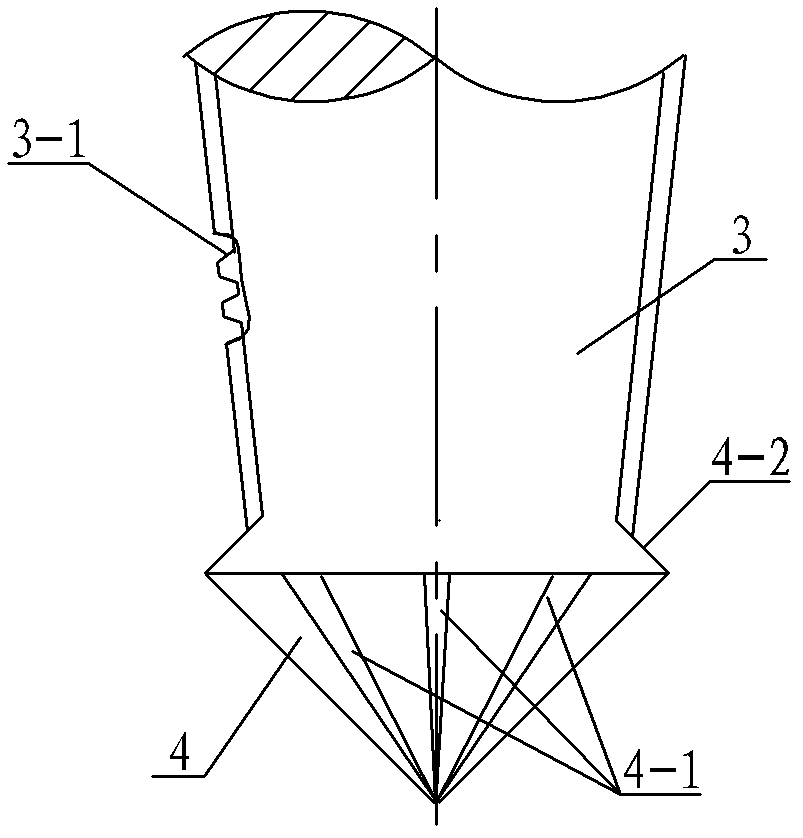

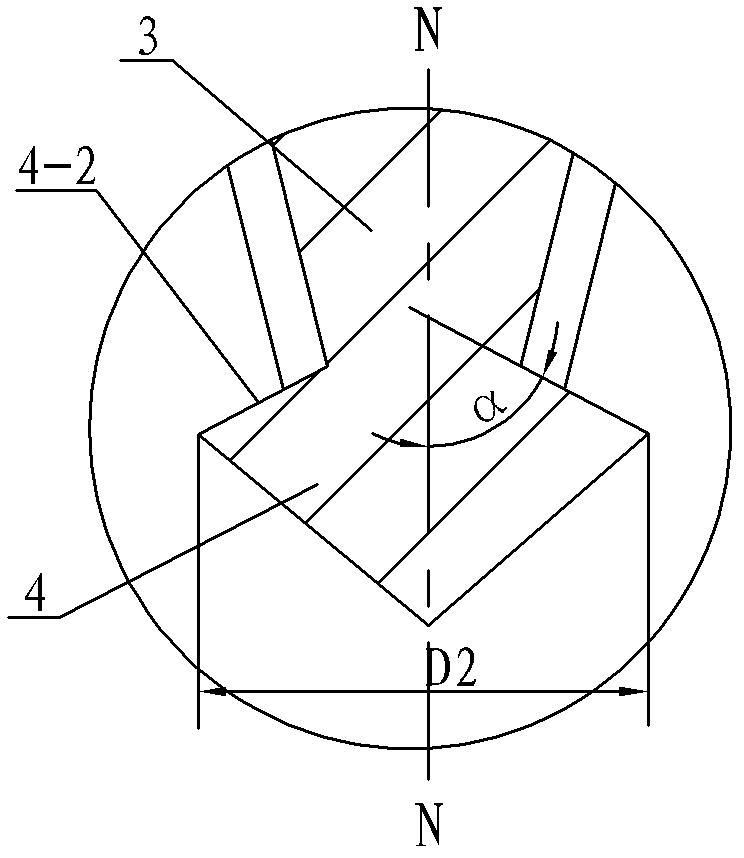

[0014] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment. This embodiment includes a clamping body and a stirring body. The clamping body includes an upper cylinder 1 and a lower cylinder 2. The stirring body includes a main stirring needle 3 and an auxiliary stirring needle 4. The upper cylinder 1 and the lower cylinder The body 2, the main stirring needle 3, and the auxiliary stirring needle 4 are arranged in sequence from top to bottom and are made into one body. The diameter of the upper cylinder 1 is smaller than the diameter of the lower cylinder 2, and a clip is provided on the outer surface of the upper cylinder 1. The holding surface 1-1, the outer surface of the lower cylinder 2 is provided with at least two annular heat insulation grooves 2-1, the main stirring needle 3 is a cone, the diameter of the upper end of the main stirring needle 3 is greater than the diameter of the lower end, the main stirring needle 3 The outer surfac...

specific Embodiment approach 2

[0015] Specific implementation mode two: combination image 3 To describe this embodiment, the angle between the convex shoulder surface 4-2 and the central axis N-N of the welding tool in this embodiment is the lower angle α, and the lower angle α is 45°-75°. The convex shoulder surface 4-2 is the shoulder surface of the auxiliary stirring needle 4. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0016] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the angle between the concave shoulder surface 2-2 and the central axis N-N of the welding tool in this embodiment is an upper angle β, and the upper angle β is 78°-82°. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com