Green sand single box feederless foundry method for glass mold

A technology of casting glass and glass molds, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve problems such as reduced pulmonary ventilation function, mental health impact, and increased positive rate, so as to ensure physical health, reduce operating intensity, The effect of improving density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

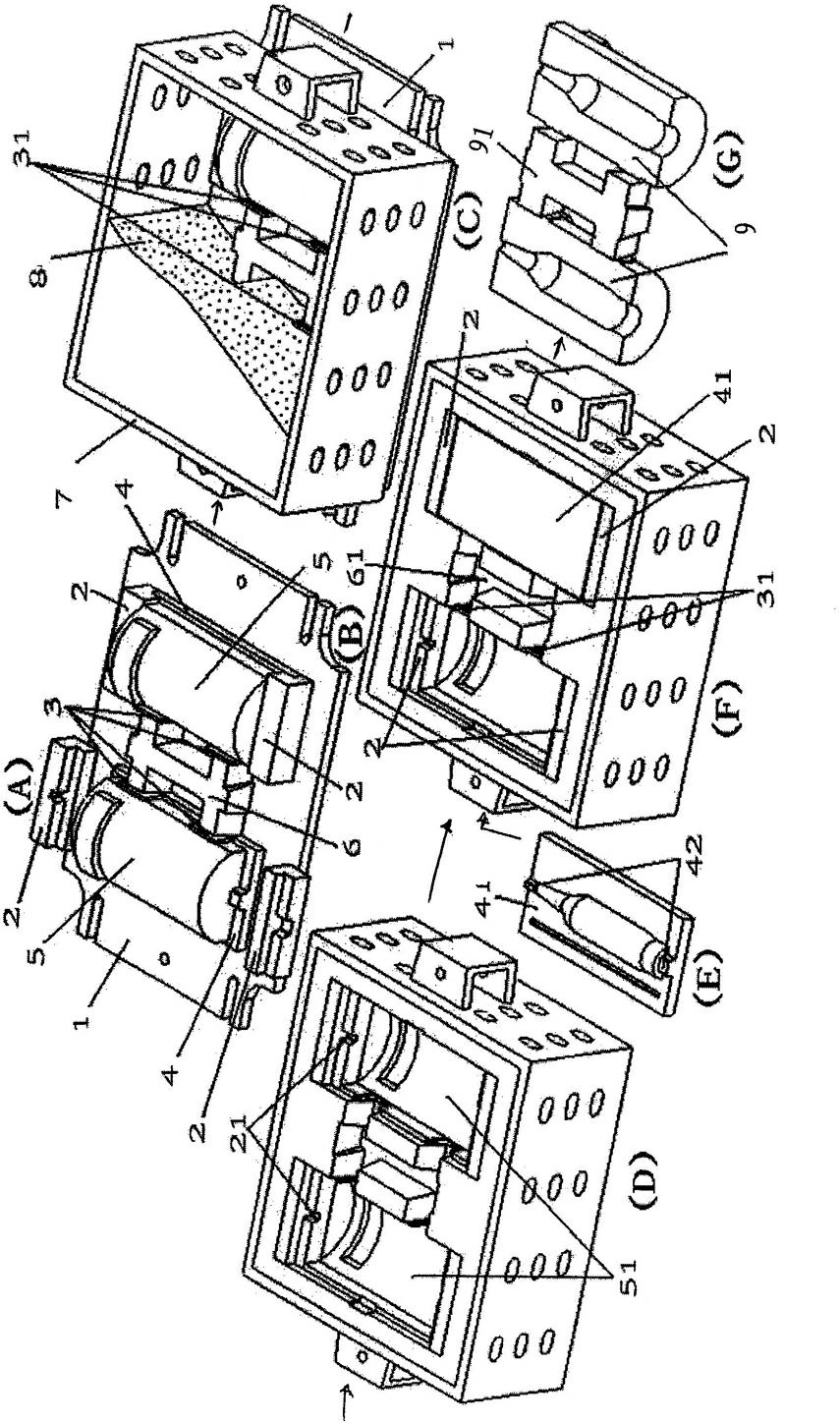

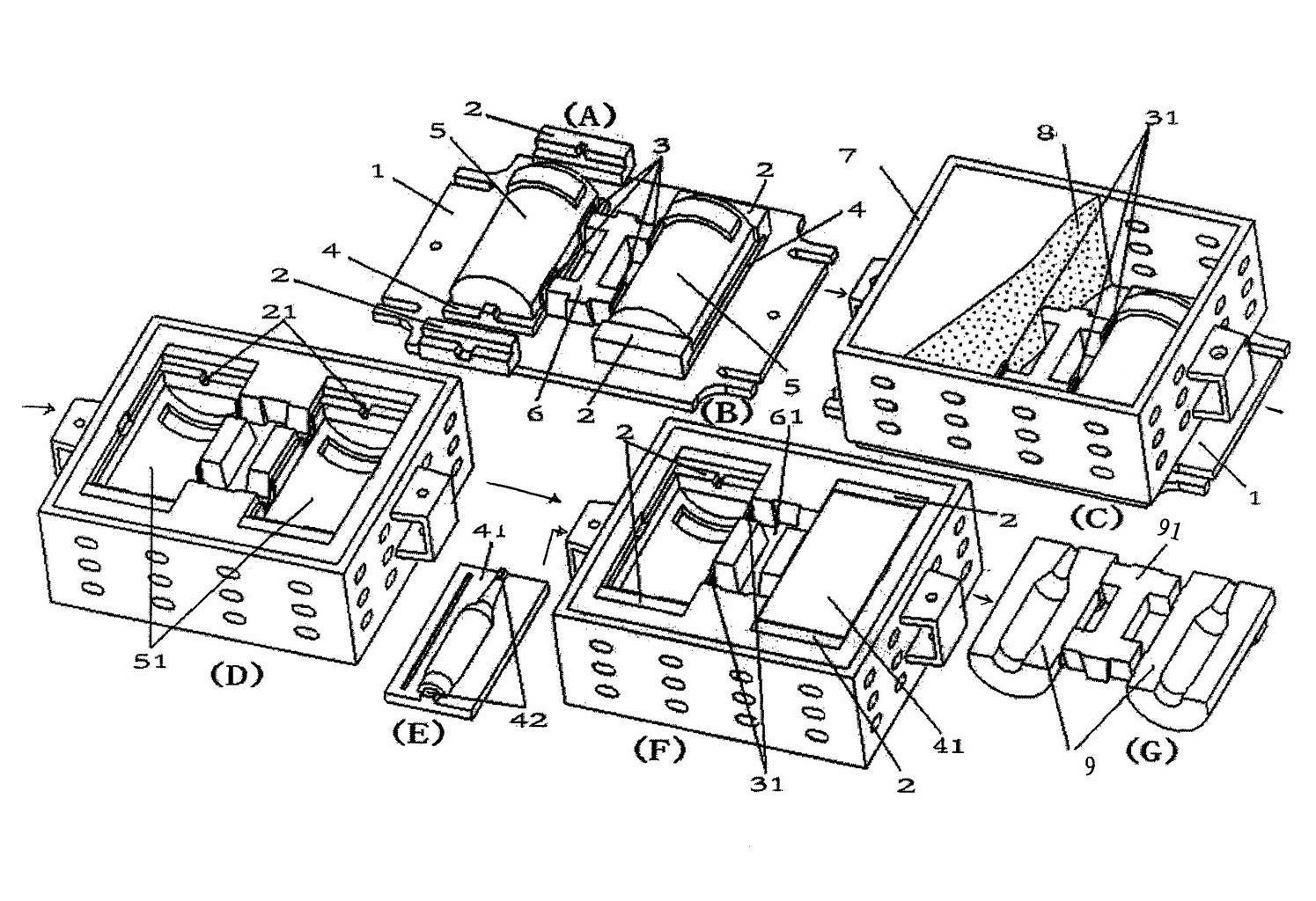

[0020] please see figure 1 and press figure 1 (A) to (G) flow shown.

[0021] First make the positioning mud core 2 for being arranged on the cold iron mud core 41 with coated sand, the quantity of positioning mud core 2 is twice of the quantity of the cold iron mud core 41, in the present embodiment, the cold iron mud core The quantity of 41 has a pair, promptly has two pieces, so the quantity of positioning mud core 2 is four, as shown in the figure, form a positioning datum groove 21 at the center position of one side of the longitudinal direction of each positioning mud core 2, here The coated sand is composed of the following raw materials in parts by weight: the original sand is silica sand for casting, and the silica sand for casting is SiO 2 98 parts of sedimentary sand with a content of 80-90%, 2 parts of phenolic resin, of which: 10 parts of urotropine and 2 parts of calcium stearate are added to every 100 parts by weight of phenolic resin; The size req...

Embodiment 2

[0024] Only change the recipe of coated sand to raw sand (SiO 2 Content is 80-90% deposition sand) 98.5 parts by weight, phenolic resin is changed into 1.5 parts by weight, wherein: the weight part of the urotropine added in every 100 parts of phenolic resin is changed into 8 parts, the weight of calcium stearate change the resin sand formula (by weight) to: 85 parts of quartz sand, 9 parts of bentonite, and 4 parts of coal powder, wherein the quartz sand is quartz sand with a moisture content of 4% over 140 mesh. All the other are the same as the description to embodiment 1.

[0025] Compared with the casting method in the prior art, the method provided by the present invention can greatly save labor and cost after switching to a single box, and reduce scrapping caused by sand falling (single box can intuitively find sand falling defects to facilitate timely cleaning of sand falling) , Put an end to the scrapping caused by the upper and lower boxes. Riser feeding is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com