Continuous cold-roll forming method for stainless steel side wall bottom edge beam

A stainless steel, cold-formed forming technology, applied in the field of profile manufacturing, can solve the problems of low bending machine processing efficiency, long production length products difficult to overcome bending and torsion phenomenon, length limitation and other problems, and achieve economic and social benefits Significant, consistent, and less deformation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0036] Such as Figure 1-4 shown.

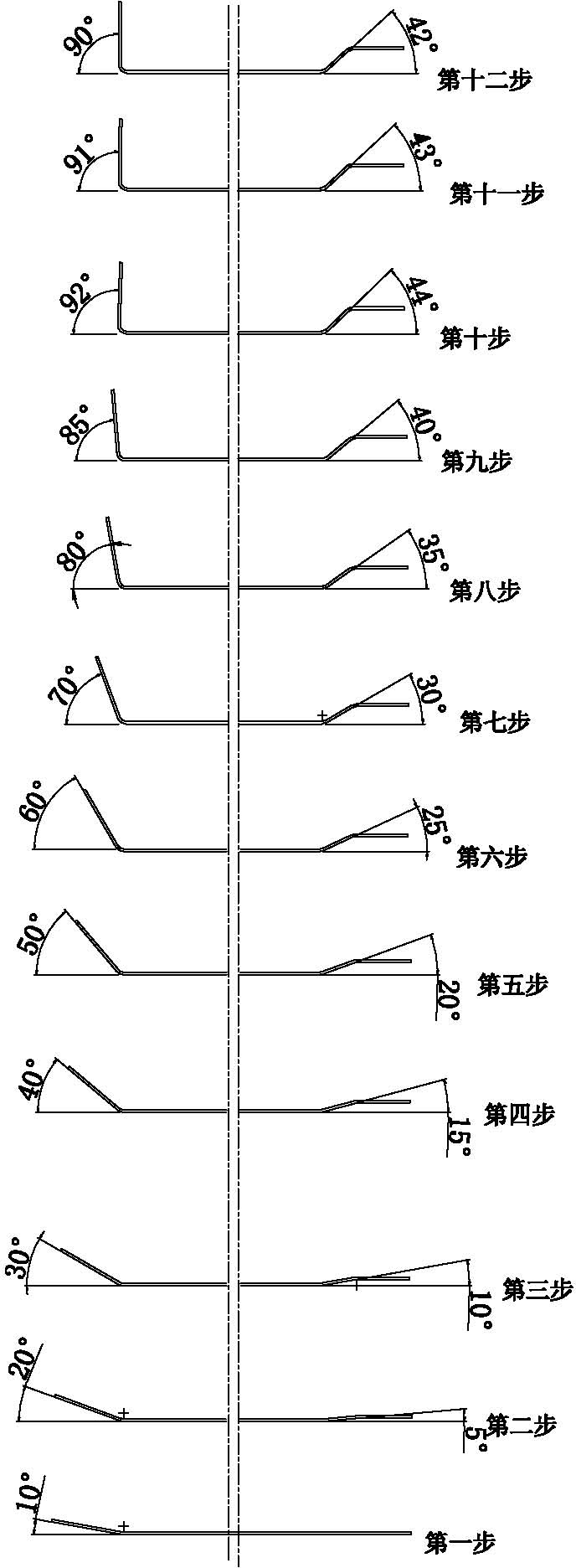

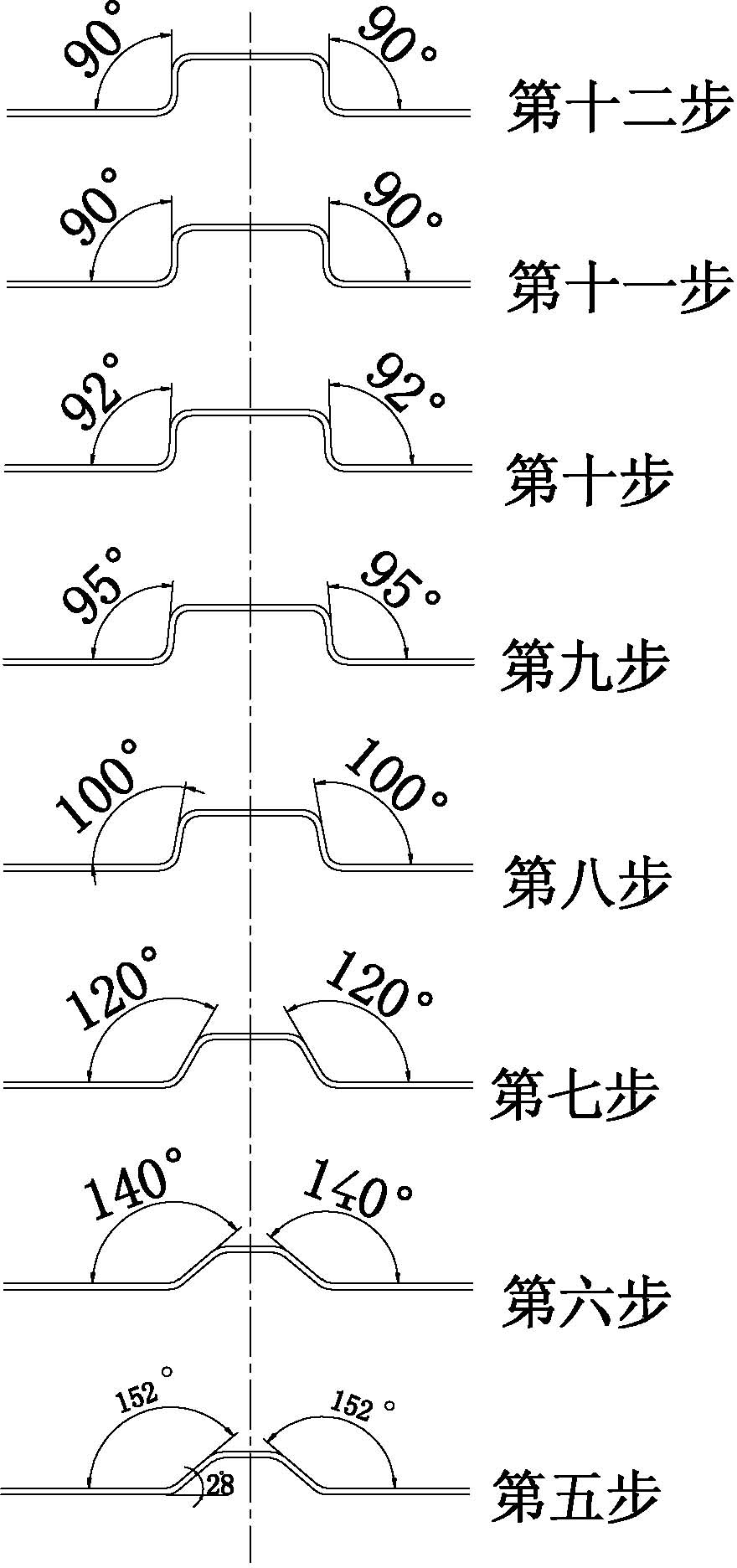

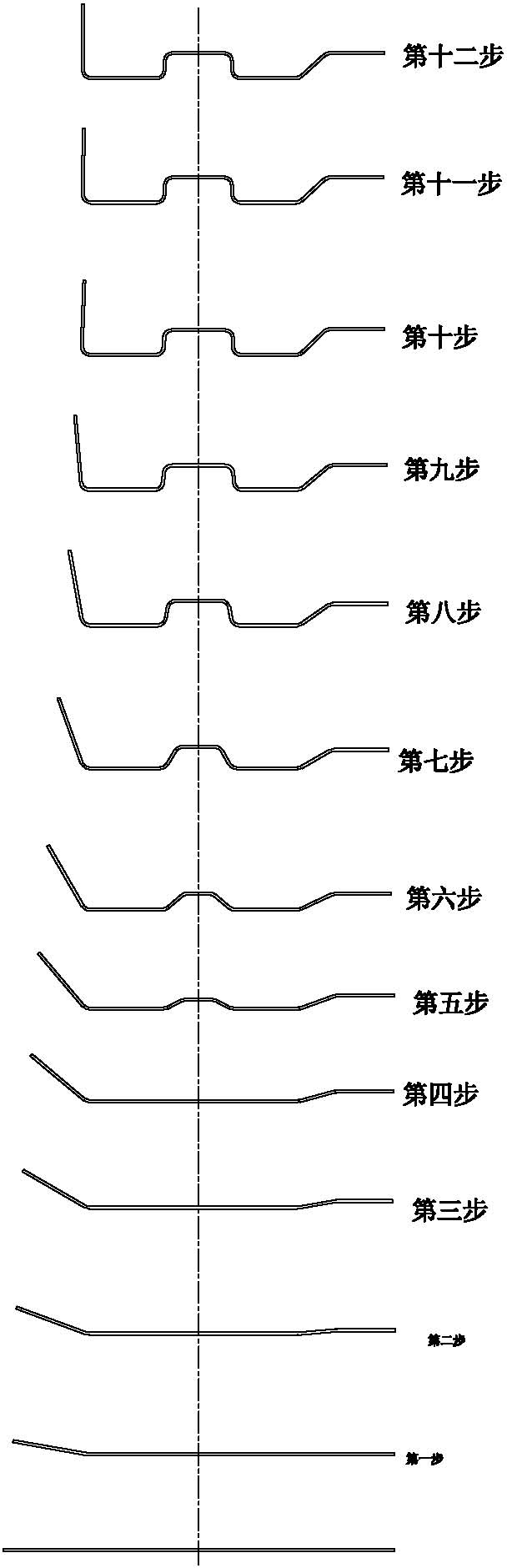

[0037] A stainless steel side wall lower side beam, forming the outer curling at the same time as forming the right-angled side, and forming the rib boss when it is about to be formed to the profile, such as figure 1 The schematic diagram of the simultaneous forming of the right-angled edge and the outer curling edge is shown, such as figure 2 Forming of the rib bosses shown, such as image 3 Forming roll patterns for stainless steel sidewall sill beams shown. Aiming at the performance of stainless steel material, two bends are used to make it better shaped. The thickness of the lower wall panel of the stainless steel side wall is 1.5mm. It can be formed by continuous roll cold bending, and the rolls are continuously rolled and deformed one by one. During the deformation process, the upper and lower rolls are use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com