Experiment system and method for tangential filtration of high pressure resistant flat reverse osmosis (RO) membrane

An experimental system and flat-plate technology, applied in the field of flat-plate RO membrane filtration experimental devices, can solve the problems of insufficient pressure bearing capacity, adjusting the speed of filtration, and inability to change the flat-plate filter, so as to achieve the effect of reducing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

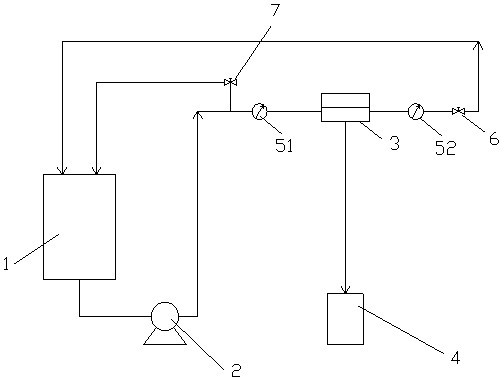

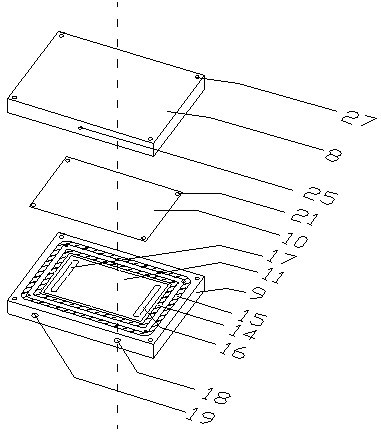

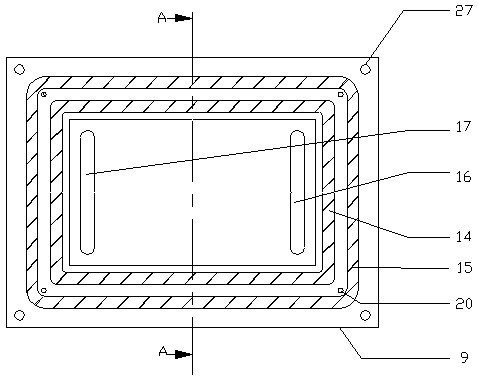

[0046] Example: see Figure 1 to Figure 8 , A high-pressure flat RO membrane tangential filtration experimental system, including:

[0047] Feeding tank 1, used to hold the material liquid;

[0048] The pressure pump 2 is set between the feed tank and the flat RO membrane filter device, and its two ends are connected with the feed tank and the flat RO membrane filter device through pipelines to transport the liquid in the feed tank to the flat RO membrane filter. Membrane filtration device, while providing high pressure required for filtration experiments;

[0049] Flat-plate RO membrane filtration device 3, used to separate the material in the liquid and split the liquid obtained after filtration; the permeate (that is, the liquid that penetrates the RO membrane) is transported to the storage tank through the pipeline for storage, and the concentrated liquid (that is The liquid that has not passed through the RO membrane) is returned to the feed tank through the return pipeline;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com