Crystallization tower for purifying phosphoric acid

A crystallization tower, phosphoric acid technology, applied in crystallization separation, phosphorus compounds, inorganic chemistry and other directions, can solve the problems of low yield of purified phosphoric acid, complicated operation steps, inconvenient continuous production, etc., to improve the separation and purification effect, continuous and stable The effect of production and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

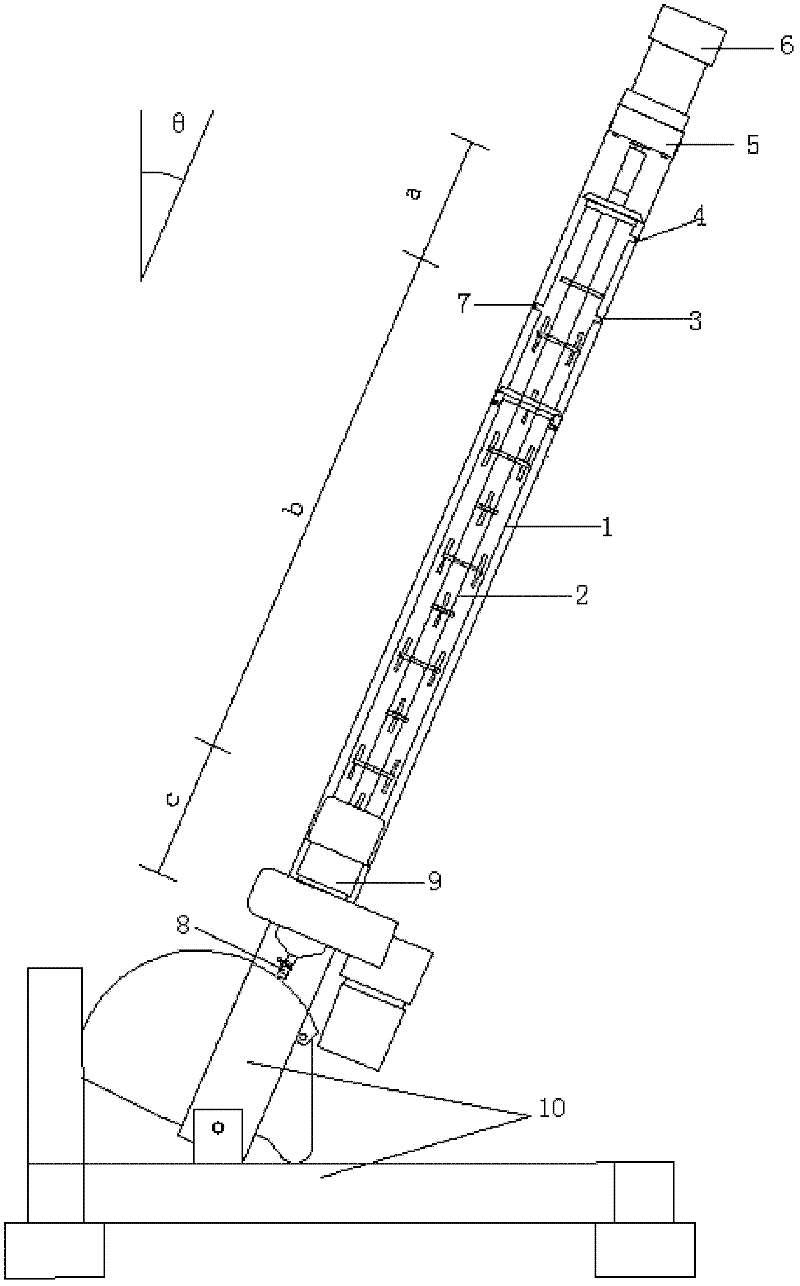

[0037] In this embodiment, the structure of the crystallization tower for purifying phosphoric acid is as follows figure 1 As shown, it includes a tower body 1, an agitator 2, a heater 9 and a driving mechanism.

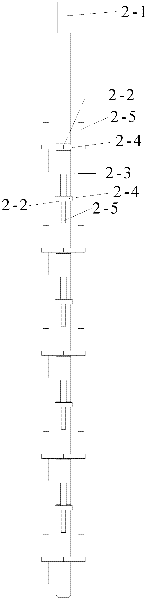

[0038] The tower body 1 is a cylindrical body, and its bottom and periphery are made of polytetrafluoroethylene. The tower body 1 is divided into a cooling crystallization section a, a separation and purification section b, and a crystal melting section c. The cooling crystallization section is located in the tower The upper part of the tower body has a length of 0.2m. The crystal melting section is located in the lower part of the tower body, and its length is 0.15m. The separation and purification section is located between the cooling crystallization section and the crystal melting section, and its length is 1m. There is a feed inlet 7 and a refrigerant inlet 3, the refrigerant inlet is located above the feed inlet 7, the upper part of the cooling crystallization ...

Embodiment 2

[0059] In this embodiment, the structure of the crystallization tower for purifying phosphoric acid is as follows figure 1 As shown, it includes a tower body 1, an agitator 2, a heater 9 and a driving mechanism. The difference from Embodiment 1 is that the tower body 1 is inclined by 5° relative to the vertical direction.

[0060] Use the crystallization tower described in this embodiment to prepare electronic-grade phosphoric acid with the same industrial phosphoric acid as in Example 1, and the process steps are as follows:

[0061] ① Arsenic removal

[0062] Add phosphorus pentasulfide to industrial phosphoric acid at a temperature of 40°C, and react for 100 minutes at 40°C under normal pressure under stirring (500r / min). After expiry, add the diatomite of phosphoric acid quality 8%, leave standstill 20min, then suction filtration, drip hydrogen peroxide in the phosphoric acid solution obtained by suction filtration, the dripping amount of hydrogen peroxide is 0.5% of des...

Embodiment 3

[0071] In this embodiment, the structure of the crystallization tower for purifying phosphoric acid is as follows figure 1 As shown, it includes a tower body 1, an agitator 2, a heater 9 and a driving mechanism. The difference from Embodiment 1 is that the tower body 1 is inclined 20° relative to the vertical direction.

[0072] Use the crystallization tower described in this embodiment to prepare electronic-grade phosphoric acid with the same industrial phosphoric acid as in Example 1, and the process steps are as follows:

[0073] ① Arsenic removal

[0074] Add phosphorus pentasulfide to industrial phosphoric acid at a temperature of 60°C, and react at normal pressure at 60°C for 60 minutes under stirring (500r / min), the amount of phosphorus pentasulfide added is twice the molar amount of arsenic contained in industrial phosphoric acid, and the reaction time After expiry, add the diatomite of phosphoric acid quality 10%, leave standstill 30min, then suction filtration, dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com