Lens separator for all-femtosecond microsurgery

A technology of microsurgery and separator, applied in the field of medical devices, can solve the problems of undiscovered patent documents, etc., and achieve the effects of facilitating recovery, reducing damage, and safe surgical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

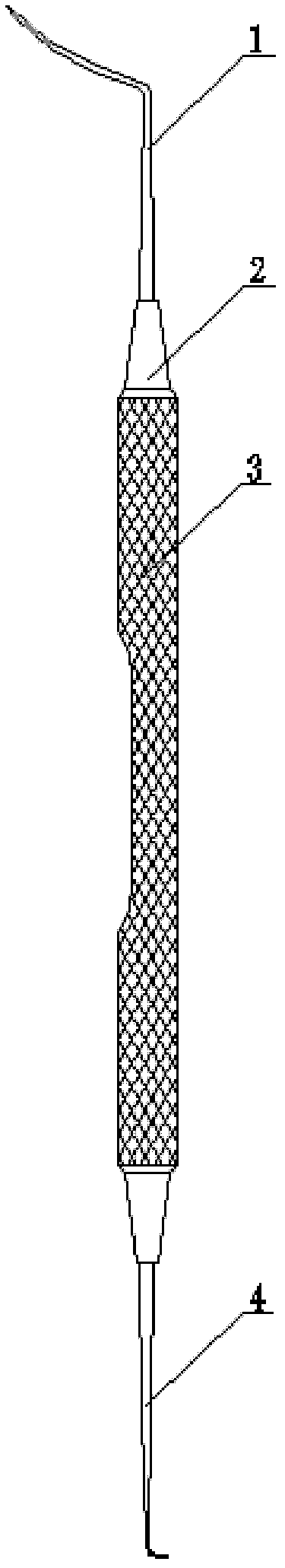

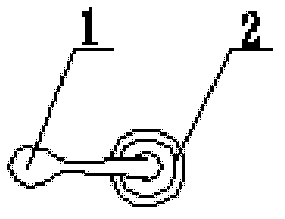

[0029] A lens separator for full femtosecond microsurgery, such as figure 1 , 2 As shown, it is composed of a separation shovel 1, a handle 2 and an incision hook 4. The separation shovel and the incision hook are coaxially fixed or integrated at both ends of the handle. The direction of the separation shovel and the incision hook is opposite; There are anti-skid lines 3 to prevent slippage of the instrument during the operation and make the operation safer.

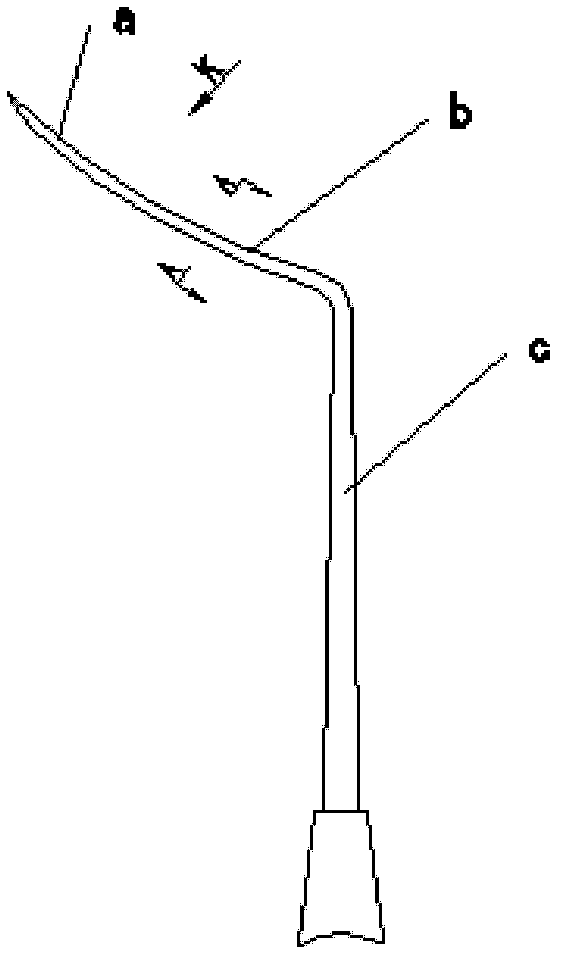

[0030] The structure of the separation shovel is as follows figure 2 , 3 , 4, 6, and 7, it is made by integrally connecting the straight bar section c, the arc section b and the round shovel section a, wherein the lower end of the straight bar section is coaxially fixed with the upper end of the handle, or it is made in one body, and its The cross-section is circular; with the extension of the upper part of the straight rod section, the diameter of the cross-section gradually becomes smaller, and turns after about 1....

Embodiment 2

[0037] A lens separator for full femtosecond microsurgery, see Figure 8 , 9 , 10, 11, 12. Its external structure also includes incision hook, handle and separation shovel, and the structure of the separation shovel 5 of the present embodiment is different from that of embodiment 1. Only the structure of the separation shovel is described below:

[0038] Such as Figure 8 , 9 As shown, the separation shovel includes a straight bar section, an arc section and a circular shovel section, but there is also a turning section f between the straight bar section and the arc section. The segment and the arc segment are reversed at an acute angle.

[0039] For the cross-sectional shapes of the straight bar section, between the turning section and the arc section, and the arc section, refer to Figure 10 , Figure 11 , Figure 12 .. The specific structure is described as follows:

[0040] The straight rod section is the direct continuation or fixed installation of the handle, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com