Preparation method for rapid-disintegrating directly-pressed particle mannitol preparation

A technology of mannitol and granules, which is applied in the field of preparation of fast-collapsing direct-pressure granule mannitol preparations, can solve the problems of increased difficulty, low pass rate, and high manufacturing costs, and achieve easy operation and control, good product quality, and low manufacturing costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Experiment with crushed mannitol:

[0010] Produce 99% granulated mannitol

[0011] formula:

[0012] Mannitol (pass 80 mesh crushing sieve) 1980g

[0013] Crospovidone 10g (internal addition)

[0014] Polyvinylpyrrolidone (K30) 10g (plus)

[0015] 1. Dissolve 10 g of polyvinylpyrrolidone (K30) in 260 g of purified water to prepare a binder slurry.

[0016] 2. Put 1980g of 80-mesh crushed mannitol and 10g of cross-linked povidone into a 4L high-speed stirring granulation pot, turn on the granulator, and add the prepared polyvinylpyrrolidone slurry for granulation. The way of low mixing and high cutting.

[0017] 3. Discharge after 240s of granulation and transfer to fluidized dryer for drying. After the material temperature is dried to 42℃, stop and discharge, use 20 mesh sieve to sieve, and the obtained upper sieve is sized on the rapid sizing machine with 20 mesh The granule sieve cage performs granulation, and then mixes to obtain the granule product.

[0018] 4. Test with 100 m...

Embodiment 2

[0023] Experiment with uncomminuted mannitol:

[0024] 99% granulated mannitol

[0025] formula:

[0026] Mannitol 1980g

[0027] Crospovidone 10g (internal addition)

[0028] Polyvinylpyrrolidone (K30) 10g (additional)

[0029] 1. Dissolve 10 g of polyvinylpyrrolidone (K30) in 240 g of purified water to prepare a binder slurry.

[0030] 2. Put 1980g of mannitol and 10g of cross-linked povidone into a 4L high-speed stirring granulation pot, turn on the granulator, add the prepared polyvinylpyrrolidone slurry for granulation, and use low agitation and high chopped the way.

[0031] 3. Discharge after 240s of granulation and transfer to fluidized dryer for drying. After the material temperature is dried to 42℃, stop and discharge, use 20 mesh sieve to sieve, and the obtained upper sieve is sized on the rapid sizing machine with 20 mesh The granule sieve cage performs granulation, and then mixes to obtain the granule product.

[0032] 4. Test with 100 mesh sieve, 22% under 100 mesh, bulk den...

Embodiment 3

[0036] Press directly with the uncomminuted crystal mannitol before:

[0037] formula:

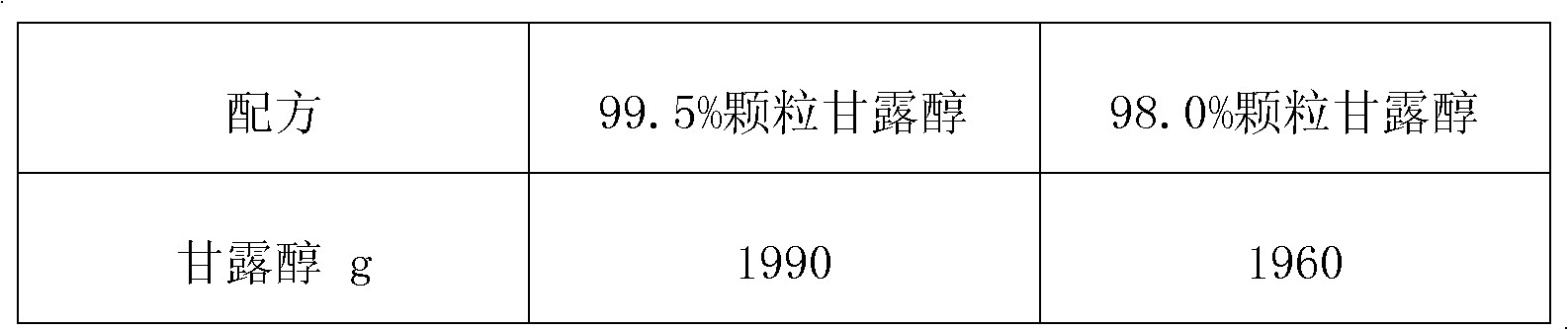

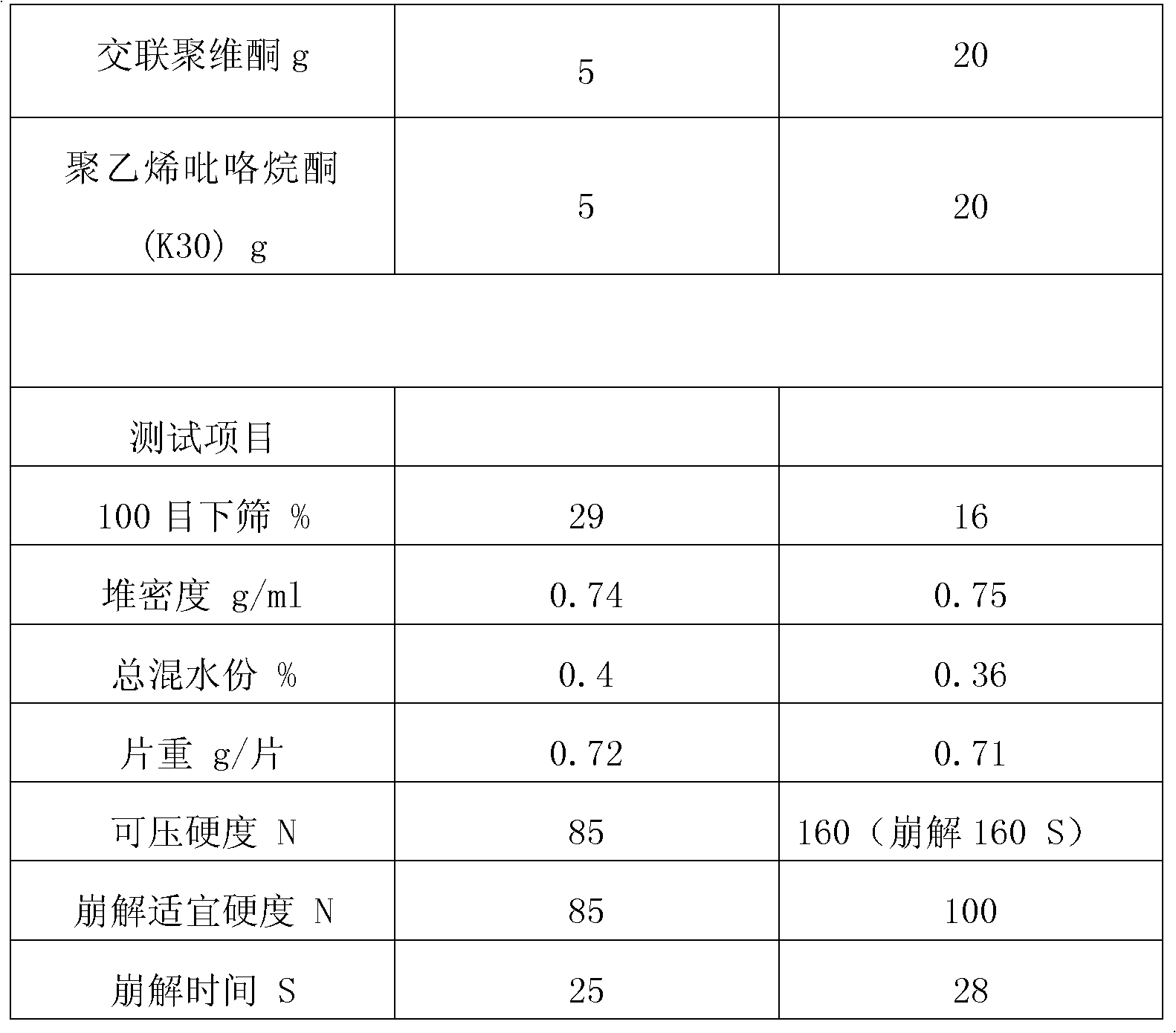

[0038]

[0039] The pressed tablet has less luster, scratches and splits on the side, which also proves that the mannitol crystal alone does need to increase the lubricant, so the lubricant is added to 1.1%, but the hardness cannot be suppressed, ¢12mm round punch, Average tablet weight: 0.724g, hardness: 24N.

[0040] In summary, it can be seen that:

[0041] 1. Domestic mannitol is directly used for tableting, with poor quality and low hardness.

[0042] 2. The present invention directly improves this situation, can achieve a very high level of hardness and content, and can ensure the disintegration time limit of the American sublingual tablet, and broaden the application field of mannitol.

[0043] 3. The use of crushed mannitol can make the hardness higher, the melting point of mannitol is higher, and there is no melting and sticking phenomenon, so it is convenient to crush and can be finer. Un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com