Sweet potato vine harvesting machine

A harvester and potato vine technology, which is applied to excavator harvesters, harvesters, excavators, etc., can solve the problems of time-consuming, wasteful, and time-consuming sweet potato harvesting, and achieve the effect of overcoming time-consuming and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

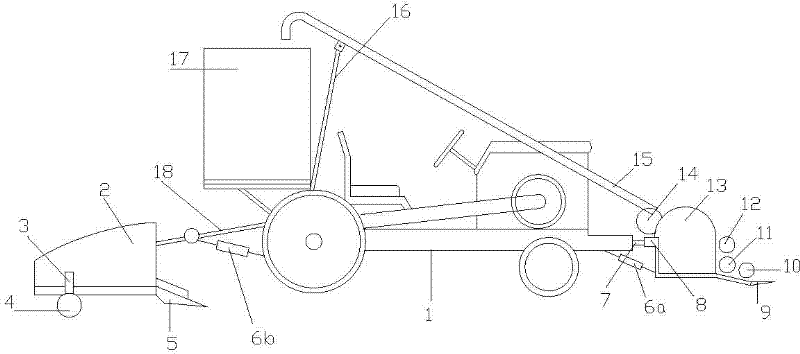

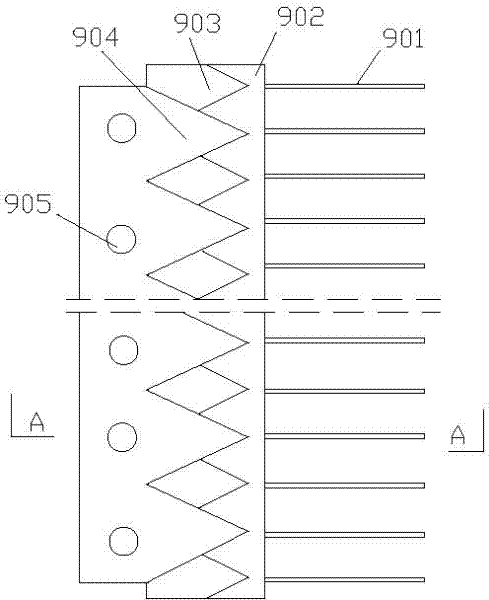

[0016] Depend on Figure 1-9 Shown, the present invention comprises tractor, rattan cutter, rattan picker, feeding roller, seedling pulverizer, blower fan, seedling conveying pipe, material storage box and potato piece harvester, it is characterized in that, tractor 1 front bumper The frame 8 is connected by a hinge 7, a hydraulic cylinder 6a is installed between the tractor and the frame 8, a seedling crusher 13 is installed on the frame 8, and a matching rattan cutter is installed on the frame at the front of the seedling crusher. 9, rattan picker 10, upper feeding roller 12, lower feeding roller 11, fan 14 and the ricer and rattan conveying pipe 15 that is connected with fan are housed on the seedling rattan pulverizer 13, a material storage box 17 is housed in the back of the tractor , a potato piece harvester 2 and hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com