Process for production of hydrogen-storing alloy composition

A technology of hydrogen storage alloy and manufacturing method, applied in chemical instruments and methods, hydrogen, non-metallic elements, etc., can solve problems such as low recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] After freezing and deactivating the spent nickel metal hydride batteries with liquid nitrogen, dry crushing with a biaxial shear crusher, then wet crushing with a dismantling grinder, and washing with water to remove plastics and paper, etc. , and then use a sieve (28 mesh) to classify, and perform magnetic separation on the non-classified material on the sieve with 2000-3000 Gauss, thereby removing the negative electrode Fe substrate. The fractionated product under the sieve is a negative electrode active material main body recovery product (negative electrode main body recovery material) in which the hydrogen storage alloy of the negative electrode is concentrated.

[0101] The proportion of the negative electrode active material in this negative electrode body recovery product (also referred to as "recycled raw material") was 88% by mass, the positive electrode active material etc. were mixed in the remainder, and the Co concentration was 9.6% by mass.

[0102] In ad...

Embodiment 2-6

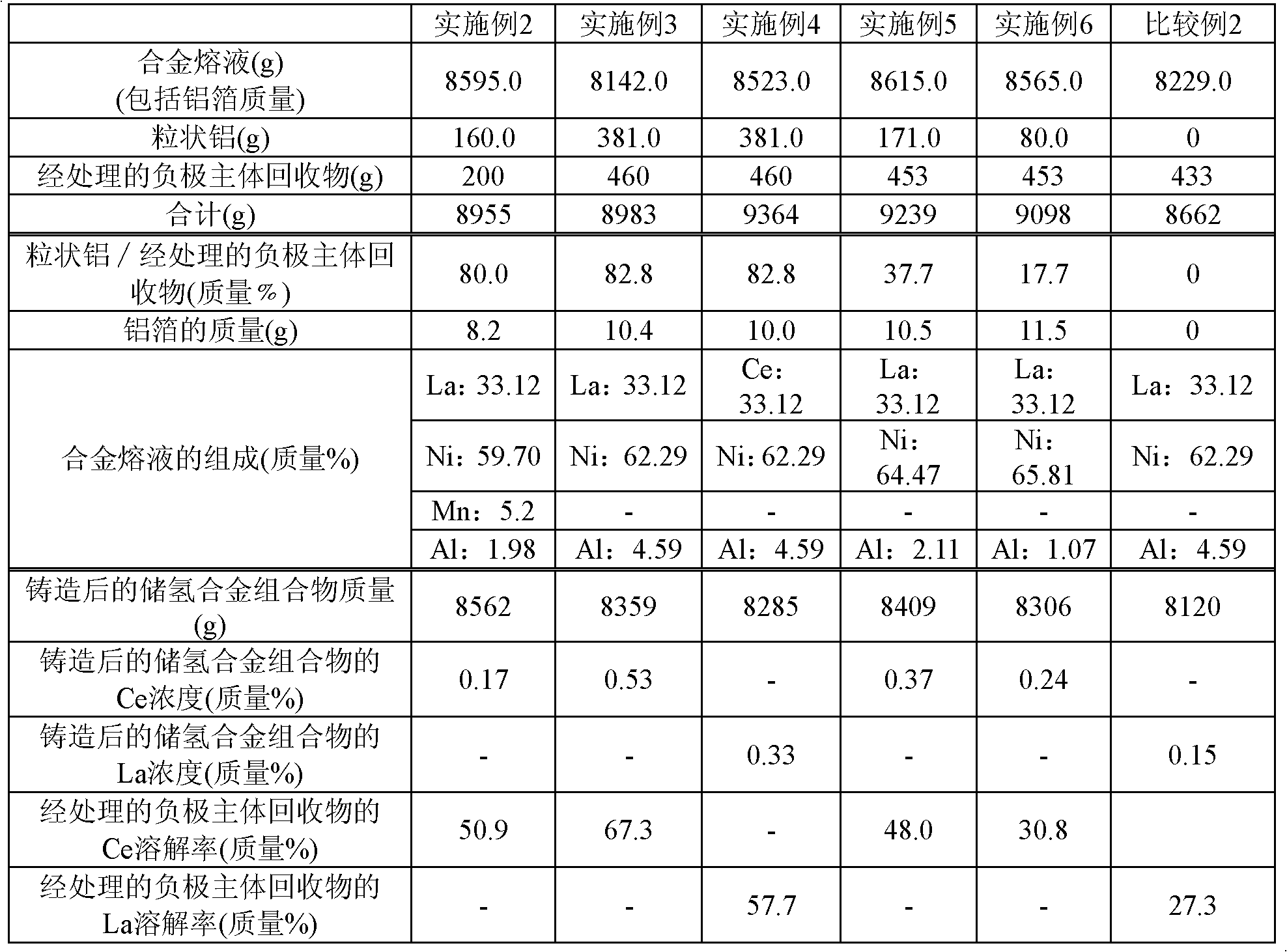

[0113] (Example 2-6, Comparative Example 2)

[0114] A product (hydrogen storage alloy composition) was obtained in the same manner as in Example 1, except that the amount of granular aluminum added, the mass of the aluminum foil wrapping it, and the composition of the molten alloy to which they were added were varied as shown in Table 2. .

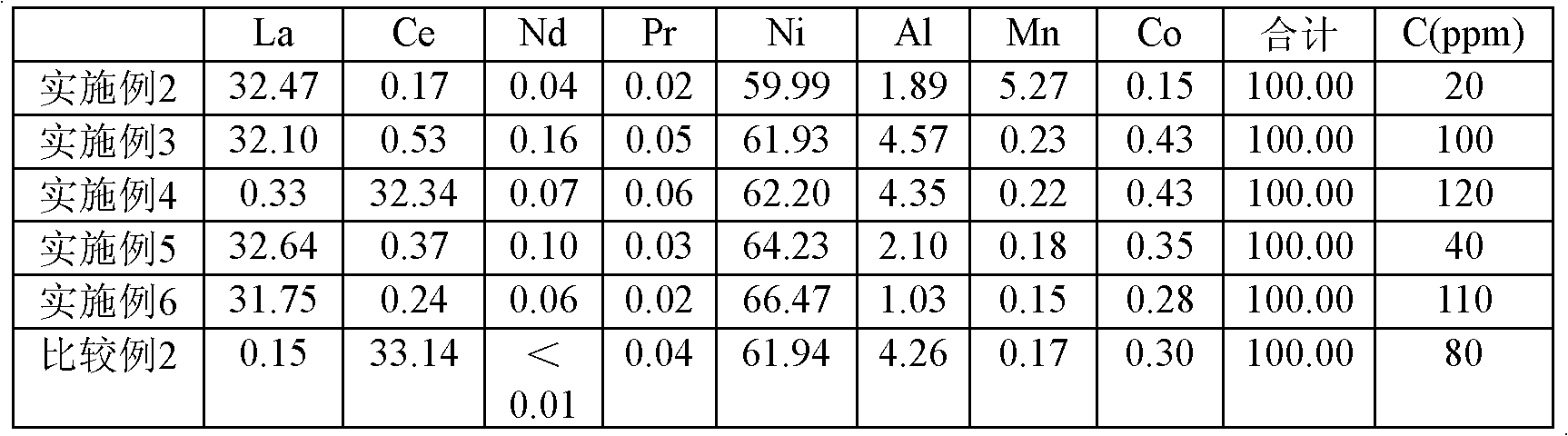

[0115] The obtained product (hydrogen storage alloy composition) was subjected to ICP analysis, and the results are shown in Table 1 below. Each numerical value in Table 1 is by mass %.

[0116] Table 1

[0117]

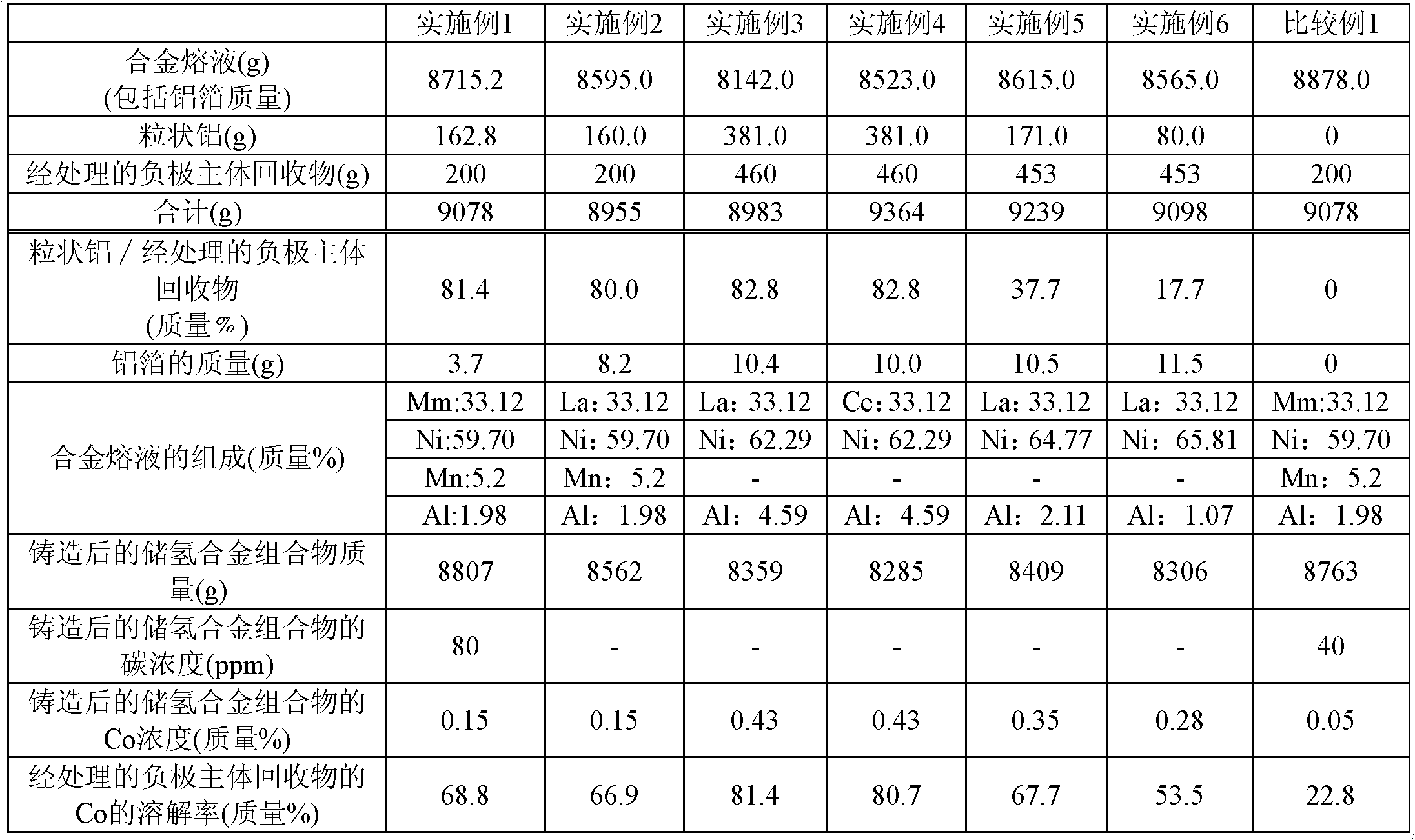

[0118] The dissolution rate (mass %) of the treated negative electrode body recovery material in Table 2 below is a value calculated by the following formula.

[0119] Dissolution rate of Co (%)=(Co content in hydrogen storage alloy composition after casting / Co content in recycled raw material)×100

[0120] Table 2

[0121]

[0122] (investigation)

[0123] From this, it can be seen that by putting aluminum and the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com