Electric spindle supported by multivariant bearing

A technology of bearing support and electric spindle, which is applied in the direction of bearings, shafts and bearings, sliding contact bearings, etc., to achieve the effects of large bearing capacity, convenient use and maintenance, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

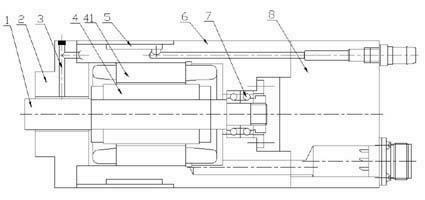

[0015] In order to further explain the technical means and functions adopted by the present invention to achieve the intended purpose of the invention, the specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0016] Such as figure 1 As shown, an electric spindle supported by multi-element bearings includes a casing, a rotating shaft arranged in the casing, a stator 41 of a built-in motor, and a rotor 4. The front end of the rotating shaft is arranged outside the casing and connected to the front cover 2 of the casing. Adjacent, the front cover 2 of the casing is provided with an oil inlet 3 for supplying pressure oil to the rotating shaft 1, and the pressure oil is supplied from the oil inlet 3 as a radial support for the output end of the electric spindle. Oil film dynamic and static pressure bearing, because the dynamic and static pressure oil film bearing has a larger ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com