Packaging method for realizing separation of fluorescent powder glue away from coating in light emitting diode (LED) package and application

A technology of LED encapsulation and encapsulation method, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve problems such as difficulties in realization, achieve high optical requirements and performance, and improve the effect of light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

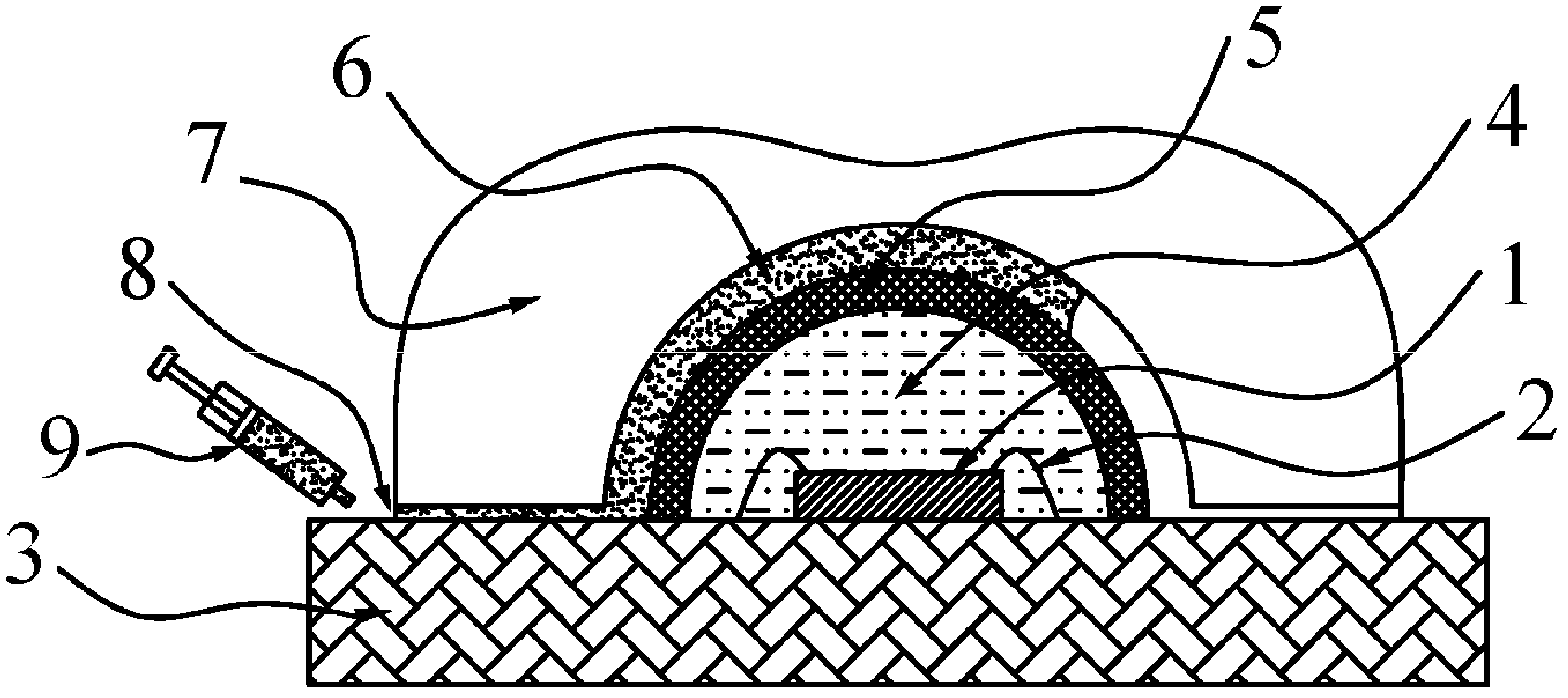

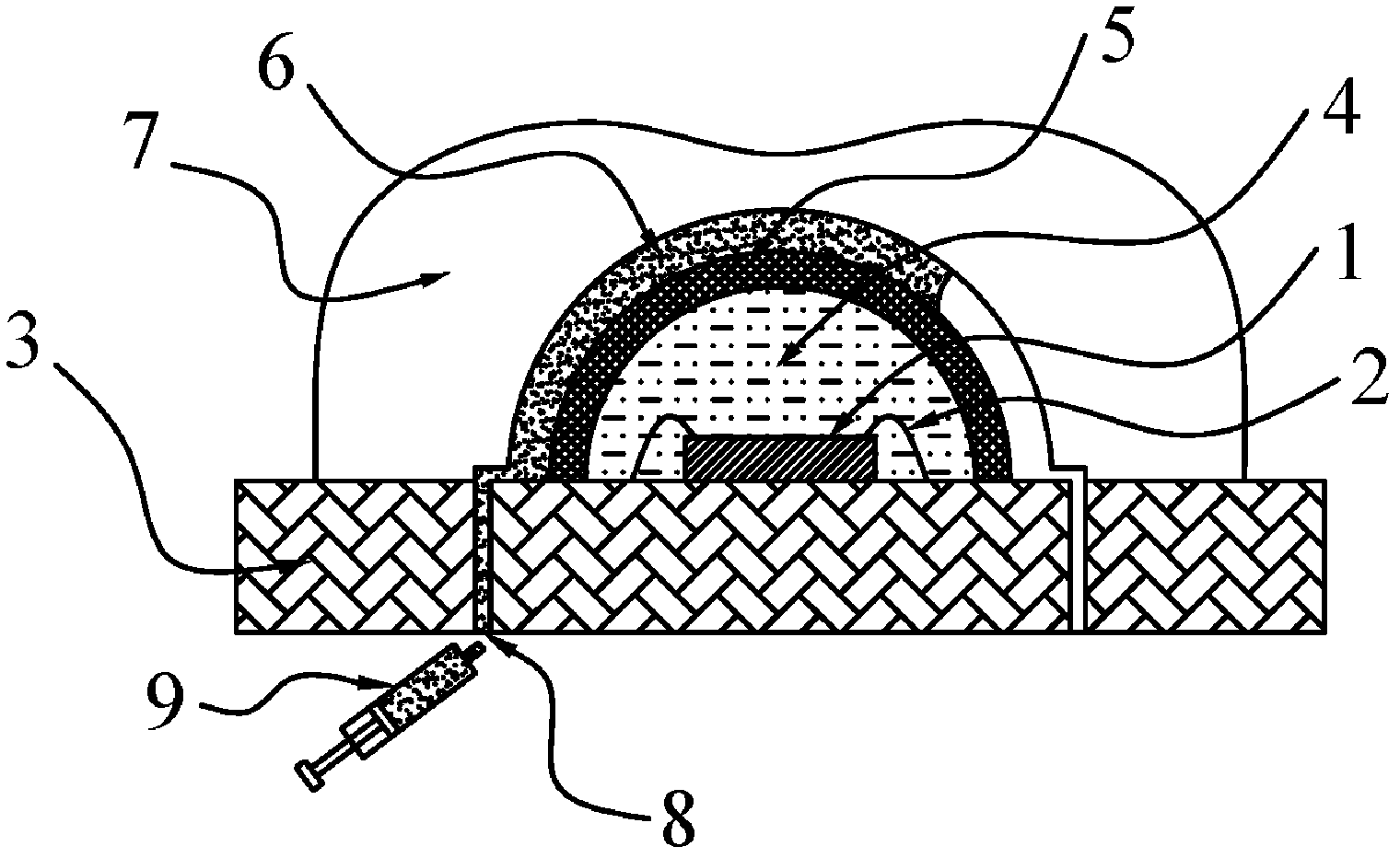

[0028] see figure 1 The LED chip 1 is fixed on the package substrate 3 by solder, and the gold wire 2 connects the LED chip 1 with the package substrate 3 to form a continuous circuit. After the traditional hemispherical primary lens 5 is installed on the substrate, it is filled with silica gel 4 . Install the secondary lens 7 on the packaging substrate 3 , and then fill the phosphor glue 6 between the primary lens 5 and the secondary lens 7 . The inner surface of the secondary lens 7 is also hemispherical, and the thickness of the phosphor glue 4 is the difference between the radius of the inner surface of the secondary lens and the radius of the outer surface of the primary lens, so that the fluorescent powder far away from the coating with uniform thickness can be obtained. Powder glue layer.

[0029] see figure 2 and image 3 , the process of filling phosphor glue 6 between the primary lens 5 and the secondary lens 7 is: inject the phosphor glue 6 in the syringe 9 fro...

Embodiment 2

[0039] see Figure 5 and Figure 6 , the difference between this embodiment and Embodiment 1 is that the inner surface of the secondary lens 7 is not hemispherical, but semi-ellipsoidal, and the thickness of the fluorescent powder glue obtained away from the coating is not uniform, but the phosphor powder glue The top thickness is small and the bottom thickness is large. The advantage of doing this is: according to the light-emitting principle of white light LED, when the blue light from LED chip 1 passes through the phosphor powder glue 6, part of the blue light will be absorbed by the phosphor powder and converted into yellow light. The yellow light converted by the phosphor is mixed to obtain white light. However, the blue light emitted by the LED chip 1 conforms to the Lambertian distribution characteristics, the light intensity at the top is the largest, and gradually decreases with the increase of the angle, while the phosphor particles have scattering characteristics,...

Embodiment 3

[0041] see Figure 7 and Figure 8 The difference between this embodiment and Embodiment 1 is that the inner surface of the secondary lens 7 is not hemispherical, and its cross section is rectangular or trapezoidal or other shapes whose inner surface top surface is a plane; the outer surface of the primary lens 5 It is a hemisphere or other shapes with a flat top surface. The advantage of this is that the flat phosphor glue with uniform or non-uniform thickness can be kept away from the coating layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com