Dye sensitized solar cell photoanode, cell and manufacturing method of photoanode

A technology of solar cells and dye sensitization, which is applied in the field of solar cells, can solve the problems of low electron transfer rate and achieve the effects of short electron transfer path, high electron transfer rate and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

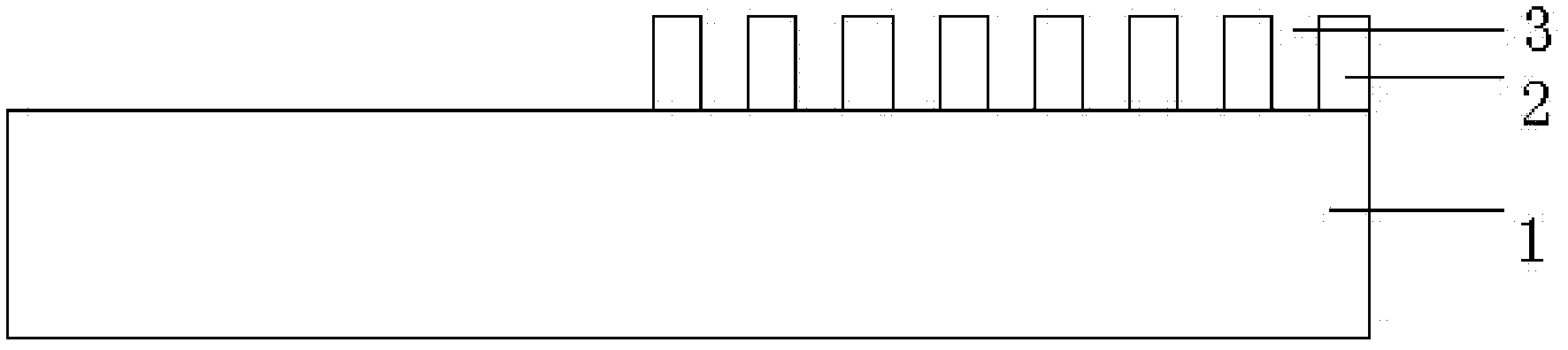

[0021] Cleaning the Ti substrate: The Ti substrate is a Ti foil plate, and the Ti substrate is ultrasonically cleaned with acetone and deionized water for 10 minutes, and then, the Ti substrate is cleaned in HF and HNO 3 Chemically polish in a mixed solution with a volume ratio of 1:1, then clean the Ti foil plate with deionized water and acetone, and finally dry it at low temperature.

[0022] form TiO 2 Nano layer: the Ti substrate is soaked in 40mmol / L TiCl 4 In the solution, the temperature was raised to 70° C., treated in a water bath for 30 minutes, and then dried.

[0023] form TiO 2 Grid layer: TiO formed by laser etching 2 nanolayer, exposing the Ti substrate, thus, forming the TiO 2 Grid layer, grid line width 0.05mm, pitch 0.05mm.

[0024] Configure the electrolyte: the electrolyte consists of NaHSO 4 h 2 O, C 6 h 5 Na 3 o 7 2H 2 O and NaF are mixed according to the material ratio of 2:2:1, and then adjusted with HF to configure the pH to be 5.0. In oth...

Embodiment 2

[0028] Cleaning the Ti substrate: The Ti substrate is a Ti foil plate, and the Ti substrate is ultrasonically cleaned with acetone and deionized water for 10 minutes, and then, the Ti substrate is cleaned in HF and HNO 3 Chemically polish in a mixed solution with a volume ratio of 1:1, then clean the Ti foil plate with deionized water and acetone, and finally dry it at low temperature.

[0029] form TiO 2 Nano layer: the Ti substrate is soaked in 40mmol / L TiCl 4 In the solution, the temperature was raised to 70° C., treated in a water bath for 30 minutes, and then dried.

[0030] form TiO 2 Grid layer: TiO formed by laser etching 2 nanolayer, exposing the Ti substrate, thus, forming the TiO 2 Grid layer, grid line width 0.05mm, pitch 0.05mm.

[0031] Configure the electrolyte: the electrolyte consists of NaHSO 4h 2 O, C 6 h 5 Na 3 o 7 2H 2 O and NaF are mixed according to the mass ratio of 4:2:1, and then the pH is adjusted to 5.0 with HF.

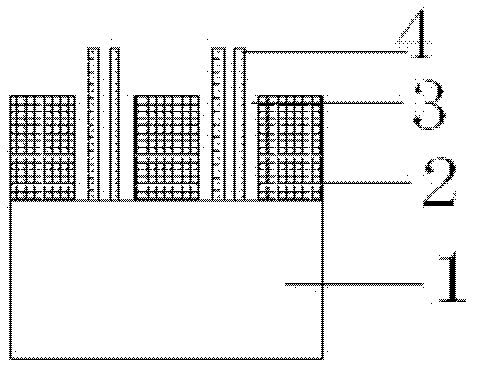

[0032] Form the TiO 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grid width | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com