NTC (negative temperature coefficient) thermistor chip, resistor and manufacturing method thereof

A thermistor chip, negative temperature coefficient technology, applied in resistors with negative temperature coefficient, resistance manufacturing, resistors and other directions, can solve the problems of easy melting of tin layer, circuit failure, thermistor falling off, etc. The effect of good resistance value consistency, high B value and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

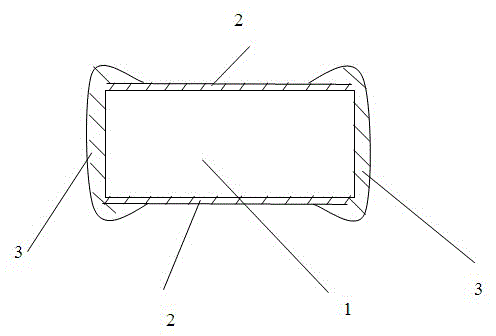

Image

Examples

Embodiment 1

[0018] MnO 2 、Ni 2 o 3 、Al 2 o 3 , Y 2 o 3 The powder is mixed according to the ratio (mole percentage) 50%: 35%: 11%: 4% to form transition metal oxide powder, which is sintered to form a negative temperature coefficient thermistor chip. The time at the sintering temperature is between 3 and 9 hours. In this example, MnO 2 、Ni 2 o 3 、Al 2 o 3 , Y 2 o 3 The molar percentage of the powder can also be: 89%: 5%: 5%: 1%, or 70%: 20%: 5%: 5%, or 55%: 30%: 13%: 2%.

Embodiment 2

[0020] MnO 2 、Co 3 o 4 、Ni 2 o 3 、Al 2 o 3 , Y 2 o 3 The powder is mixed according to the ratio (mole percentage) 60%: 15%: 15%: 15%: 5% to form transition metal oxide powder, which is sintered to form a negative temperature coefficient thermistor chip. The specific maximum sintering temperature is 1200 to 1270 °C , the time to maintain the highest sintering temperature is between 3 and 9 hours. MnO 2 、Co 3 o 4 、Ni 2 o 3 、Al 2 o 3 , Y 2 o 3 The molar percentage can also be: 50%: 10%: 25%: 11%: 4%, or 69%: 10%: 15%: 5%: 1%, or 55%: 20%: 16%: 6% : 3%.

Embodiment 3

[0022] (1) MnO 2 、Ni 2 o 3 、Al 2 o 3 , Y 2 o 3 The powder is mixed according to the ratio (mole percentage) 60%: 20%: 15%: 5% to form transition metal oxide powder, and then add a certain proportion of organic solvent and binder to prepare a slurry suitable for casting. The organic solvent can be a mixture of propyl acetate and ethanol in a ratio of 1:2 (mass percentage), and the adhesive can be polyvinyl butyral (PVB), transition metal oxide powder, organic solvent and adhesive. The ratio (mass percentage) is: 1:1.2:0.2.

[0023] (2) Prepare a 30um thick raw film sheet by casting the prepared powder slurry, and then press 20 layers of raw film sheets together to make a green sheet with a thickness of about 0.5mm, and finally place the green sheet The slices are cut into semi-finished products with a size of 1.6X0.8X0.5mm.

[0024] (3) Place the cut semi-finished product in an alumina sagger at a high temperature of 300°C for debinding (that is, organic solvents and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com