Overlap-connected shape-adjusting device used for reflecting mirror for heliostat

A technology for mirrors and heliostats, applied in the field of mirror docking and shape-adjusting devices, can solve problems such as easy interference, mirror damage, and difficulty in control, so as to reduce material breakage, adjust focus quality, and reduce The effect of strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is a detailed description of the docking shape-adjusting device for the reflector of the heliostat of the present invention in conjunction with the accompanying drawings.

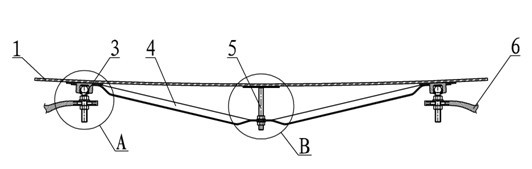

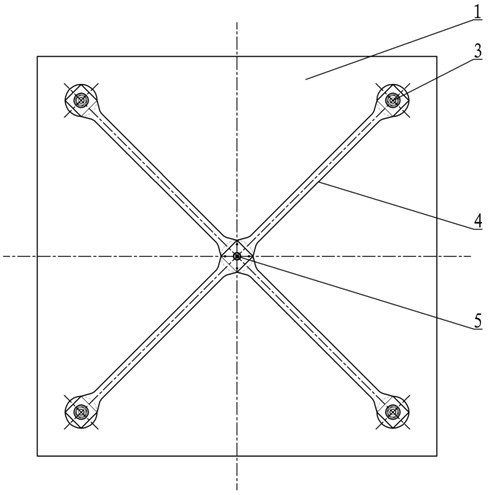

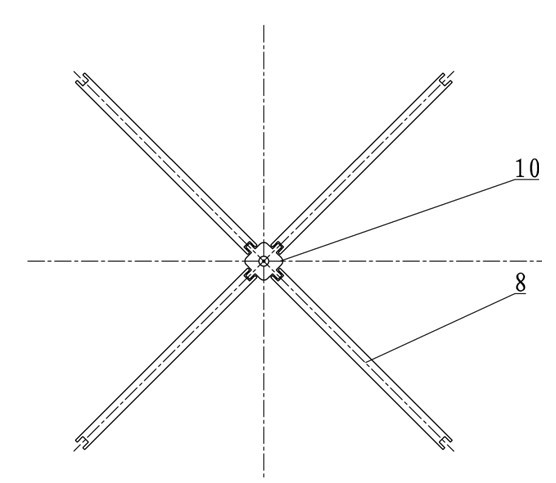

[0025] Such as figure 1 and figure 2 As shown, the reflector of the heliostat of the present invention is provided on the back of the reflector 1 of the heliostat, and is fixedly connected with the bracket 6 of the heliostat; the adjuster of the heliostat includes four Connect the shape-adjusting connector 3, a shape-adjusting claw 4 and a central shape-adjusting connector 5, the central shape-adjusting connector 5 is used to adjust the curvature of the reflector, and the docked shape-adjusting connector 3 is used to adjust the surface of the reflector type and spatial angle. During specific implementation, the number of docked shape-adjusting connectors 3 and center-adjusting shape-adjusting connectors 5 can be set according to the size and shape of the reflector, but the docking-ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com