Thermal battery test system

A test system and thermal battery technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of low reliability, cumbersome operation, inconvenient use, etc., and achieve the effect of improving accuracy and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

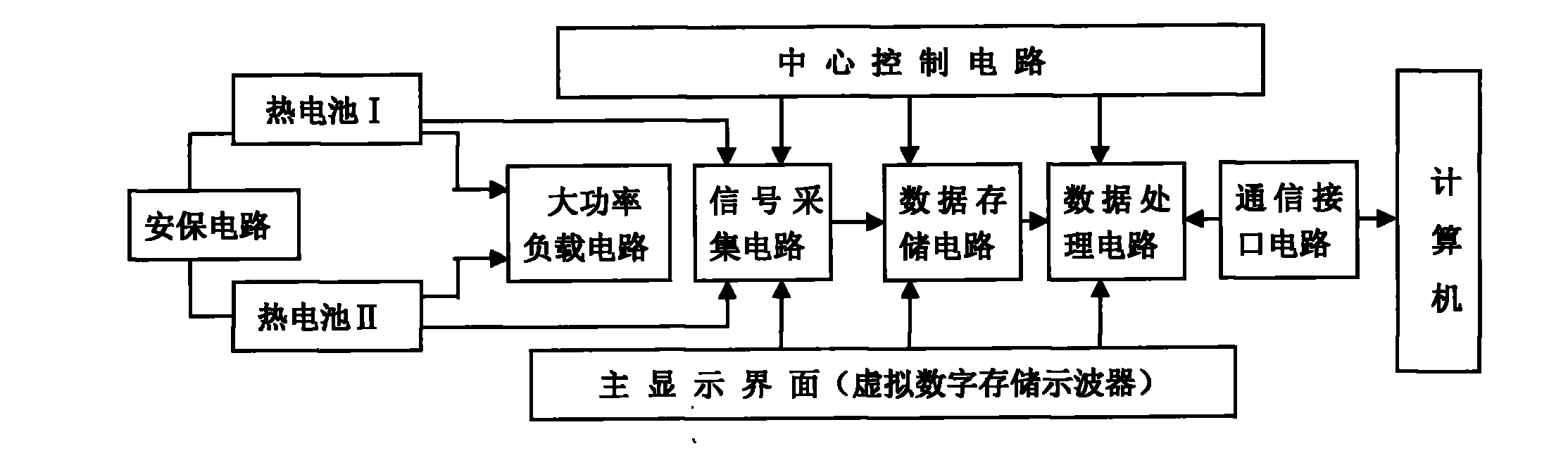

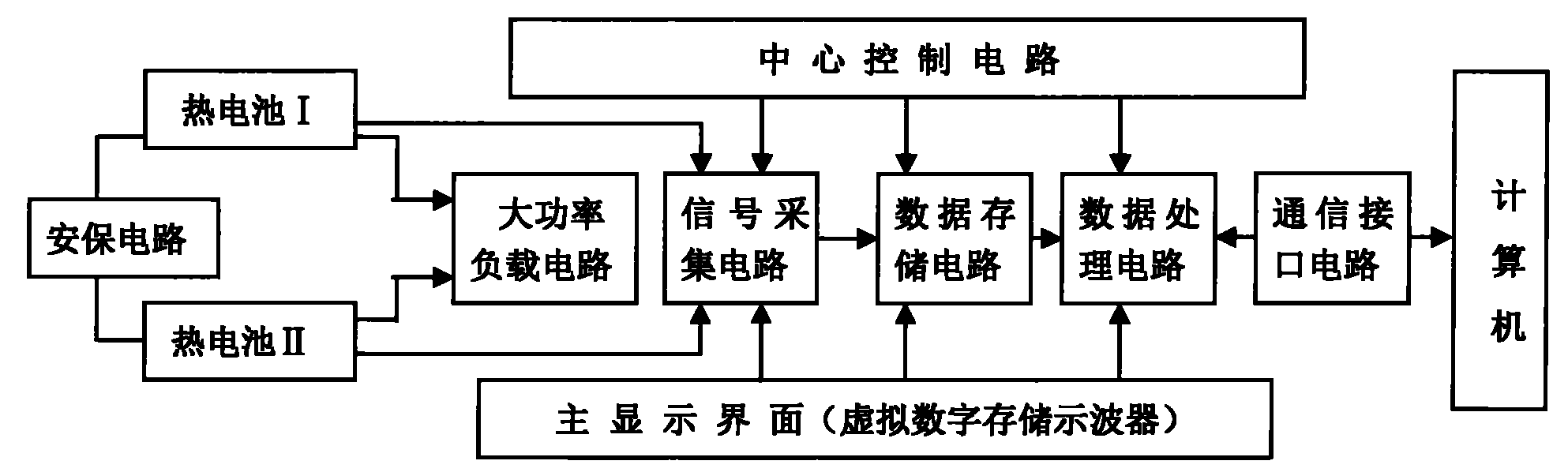

[0023] A kind of thermal battery testing system in the present embodiment, its structural composition is as follows figure 1 As shown, including thermal battery, central control circuit, high-power load circuit, signal acquisition circuit, data storage circuit, data processing circuit system, security circuit and main display module;

[0024] The connection relationship of the above components is as follows:

[0025] The central control circuit is connected with the signal acquisition circuit, data storage circuit, and data processing circuit system; the comprehensive control circuit of CPLD+ARM is selected, and the characteristics of high density, high performance and strong driving ability of CPLD chip and the advanced control application of ARM microprocessor are used Technology, combining the advantages of both, to ensure the high-speed test functi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com