Heat pipe radiator for high-power LED lamp

A heat pipe radiator, LED lamp technology, applied in semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, lighting and heating equipment, etc., to achieve the effects of reducing weight, reducing installation difficulty, and improving safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but this is not intended to limit the present invention. The scope of protection of the present invention is subject to the contents of the claims. protection scope of the present invention.

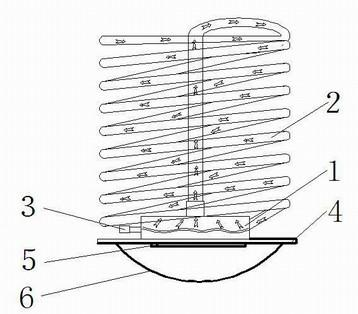

[0023] Such as figure 1 As shown, the evaporation chamber 1 and the pipeline 2 on it are sealed and connected to form a closed circulation loop, and chemical working fluid is injected inside to form a heat pipe.

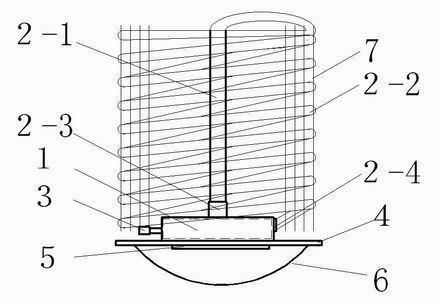

[0024] Such as figure 2 As shown, the hollow box-shaped evaporation chamber 1 is sealed and connected to the linear evaporation section 2-1 of the pipeline through the evaporation port 2-3, and the return port 2-4 is connected to the evaporation chamber 1 through the spiral return section 2-2 of the pipeline. Sealed connection, vacuuming from the filling port 3, filling chemical working fluid, sealing the filling port 3 to form a heat pipe, welding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com