Auxiliary engagement device for clutch

A technology for engaging devices and clutches, applied to clutches, mechanical equipment, etc., which can solve problems such as high cost, high operating level requirements, and clutch wear, and achieve the effects of low cost, simple control mode, and extended life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following are specific embodiments of the present invention, and further describe the technical solution of the present invention in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

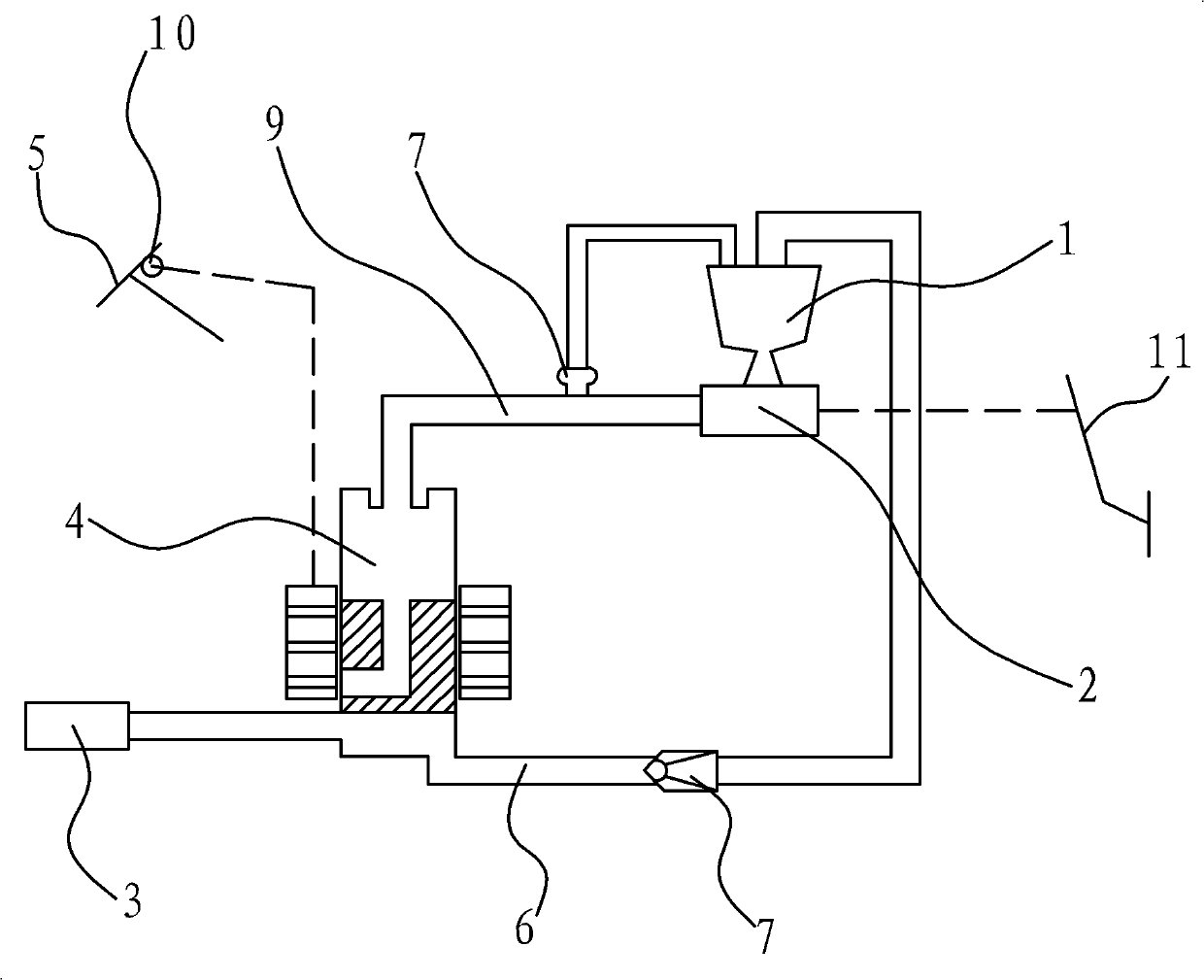

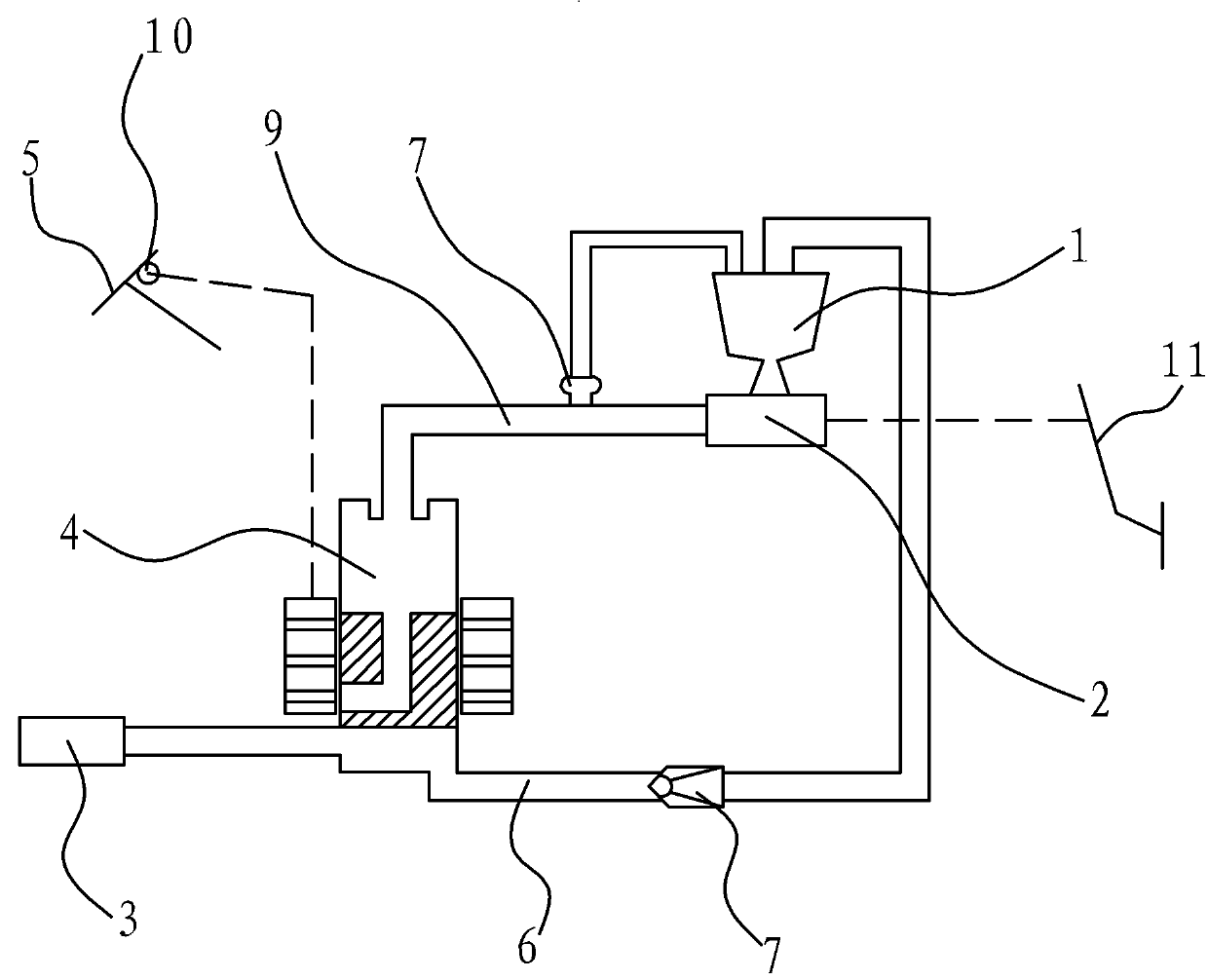

[0018] Such as figure 1 As shown, the clutch auxiliary engagement device is set in the clutch hydraulic control mechanism, which is mainly composed of a liquid storage cylinder 1, a master cylinder 2 communicated with the liquid storage cylinder 1, and a working cylinder 3 connected with the clutch. The clutch auxiliary engagement device is mainly located between the master cylinder 2 and the working cylinder 3 of the clutch hydraulic control mechanism. The clutch auxiliary engagement device is mainly composed of a solenoid valve 4 and a control circuit for controlling the opening or closing of the solenoid valve 4. The specific details of the control circuit The structure includes an automobile ECU and a position sensor 10 conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com