Recovery process of waste materials generated in industrial manufacture process of poly-p-phenylene terephthamide aramid fiber II

A poly-p-phenylene terephthalamide aramid fiber and poly-p-phenylene terephthalamide technology, which is applied in the field of synthetic fibers, can solve problems such as endangering environmental safety, and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043]Recycling process of waste generated during industrial manufacturing of polyparaphenylene terephthalamide aramid fiber II:

[0044] A. Waste pretreatment:

[0045] a. Dry the unwound aramid II dry yarn in an oven at 120°C for 20 minutes;

[0046] b. Immediately soak the unwound aramid II wet yarn in supersaturated NaHCO 3 In the solution, take it out after 2 hours, rinse it with industrial water for 4 times, until the surface of the wet yarn fiber is weakly alkaline and have a pH value of 7.0, then dry the wet yarn at 120°C for 4 hours, and the moisture content of the fiber is 8%; Add the wet yarn waste into the slurry mixing kettle, add 99% sulfuric acid to prepare a concentration of 19.4% by the weight of the waste yarn;

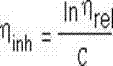

[0047] c. During the spinning operation, use a plastic bag to collect the leaked poly-p-phenylene terephthalamide / sulphuric acid spinning, then allow it to solidify at room temperature, and store it in a sealed barrel; The logarithmic viscosity o...

Embodiment 2

[0053] Recycling process of waste generated during industrial manufacturing of polyparaphenylene terephthalamide aramid fiber II:

[0054] A. Waste pretreatment:

[0055] a. Dry the unwound aramid II dry yarn in an oven at 140°C for 45 minutes;

[0056] b. Immediately soak the unwound aramid II wet yarn in supersaturated NaHCO 3 In the solution, take it out after 24 hours, rinse it with industrial water for 10 times, until the surface of the wet yarn fiber has a weakly alkaline pH value of 9.0, then dry the wet yarn at 140°C for 12 hours, and the moisture content of the fiber is 4%; Add the wet yarn waste material to the slurry mixing kettle, and add 100% sulfuric acid to prepare a concentration of 19.3% by the weight of the waste yarn;

[0057] c. During the spinning operation, use a plastic bag to collect the leaked poly-p-phenylene terephthalamide / sulphuric acid spinning, then allow it to solidify at room temperature, and store it in a sealed barrel; Polymers containing...

Embodiment 3

[0063] Recycling process of waste generated during industrial manufacturing of polyparaphenylene terephthalamide aramid fiber II:

[0064] A. Waste pretreatment:

[0065] a. Dry the unwound aramid II dry yarn in an oven at 130°C for 33 minutes

[0066] b. Immediately soak the unwound aramid II wet yarn in supersaturated NaHCO 3 In the solution, take it out after 13 hours, wash it with industrial water for 7 times, until the surface of the wet yarn fiber has a weak alkaline pH value of 8.0, then dry the wet yarn at 130°C for 8 hours, and the moisture content of the fiber is 6%; Add the wet yarn waste into the slurry mixing kettle, and add 99.5% sulfuric acid to prepare a slurry with a concentration of 19.35% by the weight of the waste yarn;

[0067] c. During the spinning operation, use a plastic bag to collect the leaked poly-p-phenylene terephthalamide / sulphuric acid spinning, then allow it to solidify at room temperature, and store it in a sealed barrel; Polymers contain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com