Method for processing coke by electrolytic aluminium waste and special device

A technology of electrolytic aluminum and coke, applied in coking ovens, petroleum industry, coking carbon-containing materials, etc., can solve problems such as secondary pollution and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

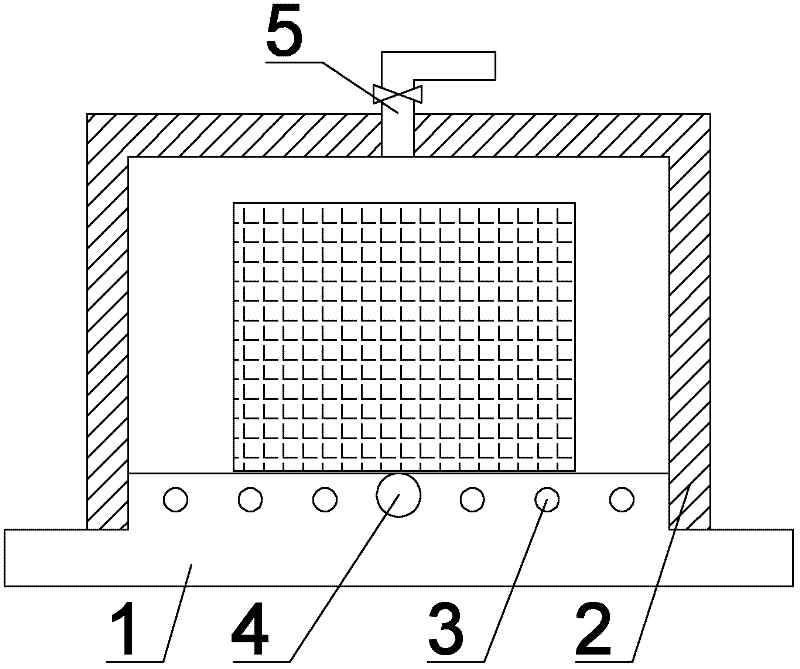

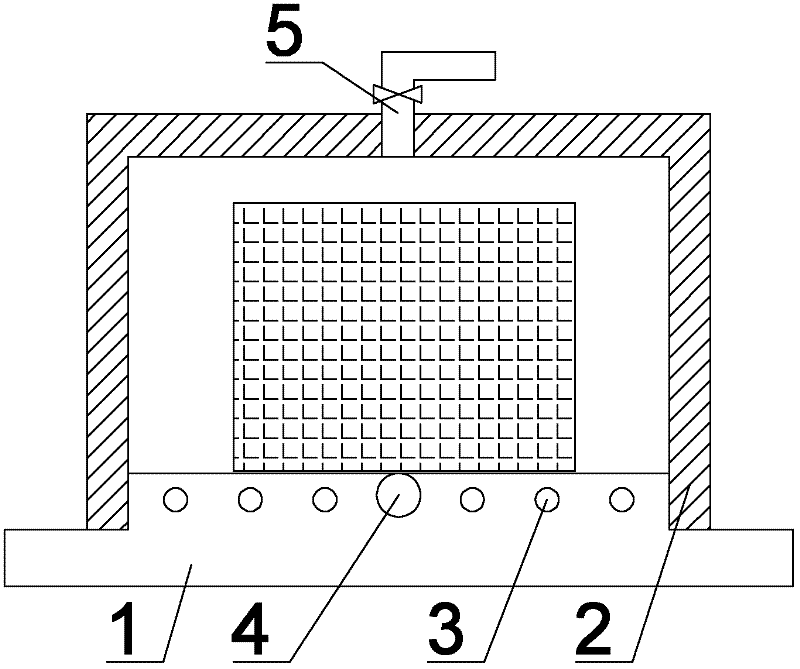

[0022] Embodiment 1 of the present invention. Such as figure 1 As shown, for the electrothermal dry distillation device, a base 1 is made, and a heat preservation cover 2 is arranged on the base 1. The heat preservation cover 2 should be sealed, and an electric heating wire 3 for heating and a thermocouple 4 for temperature measurement are installed in the base 1 to realize heating. For the control of temperature, a pipeline 5 connected to the shower system is installed on the top of the insulation cover body 2 .

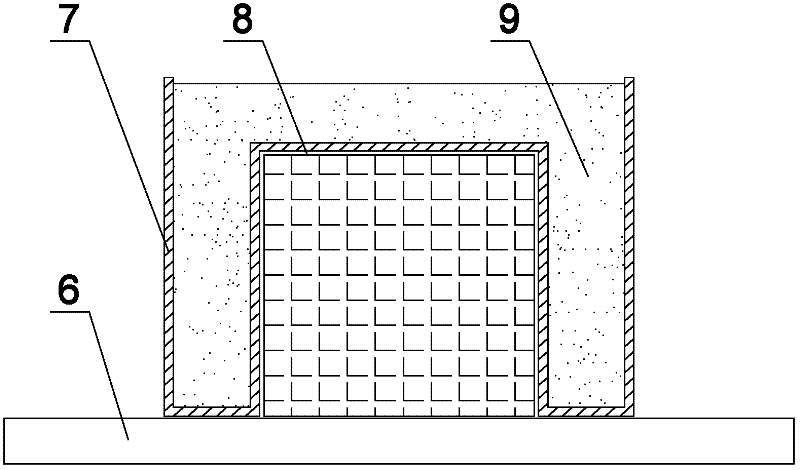

[0023] Such as figure 2 As shown in the waste heat utilization device, a bottom plate 6 is made, and a high-temperature coke product after dry distillation is placed, and a container 7 is placed on the bottom plate 6. In the middle of the container 7 is an inner cavity 8 for containing coke products. The empty groove 9 of plain material, the cross-sectional shape of the container 7 in this embodiment is like an inverted concave shape, which can cover the coke pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com