Novel bamboo fiber/polypropylene composite material and method for preparing same

A composite material, bamboo fiber technology, applied in the field of polypropylene materials, can solve problems such as difficulties, and achieve the effects of increasing flow rate, reducing melt viscosity, and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

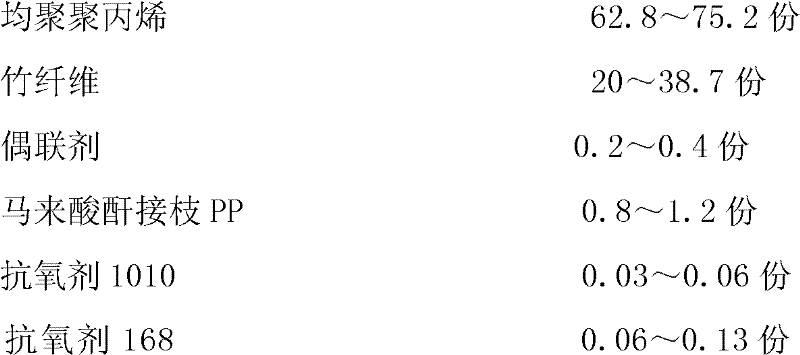

[0033] Get the raw material of following parts by weight:

[0034]

[0035]

[0036] Concrete preparation method carries out as follows:

[0037] 1. Surface treatment of bamboo fiber: Put the bamboo fiber into a high-speed mixer at 110°C and stir for 50 minutes. After the bamboo fiber is fully dried, cool it to 60°C, then add titanate coupling agent, and heat it at 70°C. Under the temperature condition, carry out the stirring treatment of 3 minutes;

[0038] 2. Put the above-mentioned treated bamboo fiber, homopolypropylene, maleic anhydride grafted PP, antioxidant 1010, antioxidant 168, lubricant and molecular weight regulator into a high-speed mixer and mix evenly, then add to Extruding and granulating in a twin-screw extruder is the novel bamboo fiber / polypropylene composite material, wherein the twin-screw extruder is a parallel meshing twin-screw extruder with a length-to-diameter ratio of 40-40. 48. The barrel is equipped with 6 to 9 heating units and 1 to 2 exha...

Embodiment 2

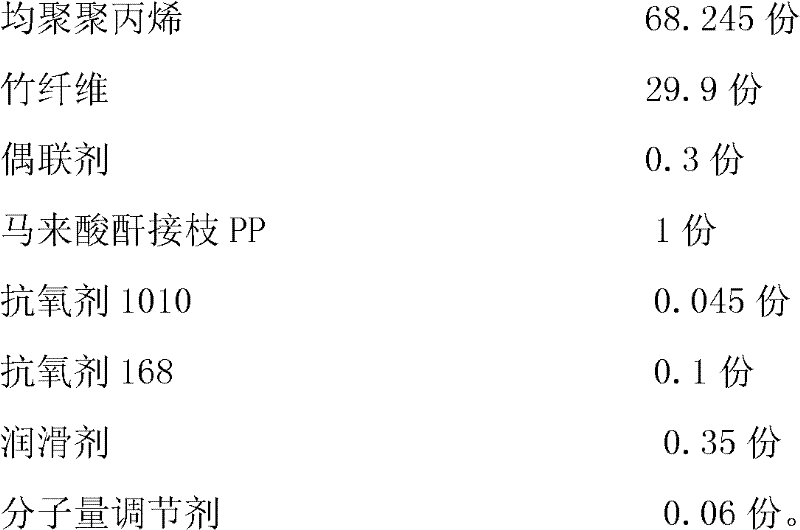

[0040] Get the raw material of following parts by weight:

[0041]

[0042] Concrete preparation method carries out as follows:

[0043] 1. Surface treatment of bamboo fiber: Put the bamboo fiber into a high-speed mixer at 100°C and stir for 60 minutes. After the bamboo fiber is fully dried, cool it to 65°C, then add titanate coupling agent, and heat it at 80°C. Under the temperature condition, carry out the stirring treatment of 5 minutes; Others are the same as embodiment 1.

Embodiment 3

[0045] Get the raw material of following parts by weight:

[0046]

[0047] Concrete preparation method carries out as follows:

[0048] 1. Surface treatment of bamboo fiber: Put the bamboo fiber into a high-speed mixer at 120°C and stir for 40 minutes. After the bamboo fiber is fully dried, cool it to 70°C, then add titanate coupling agent, and heat it at 75°C. Under the temperature condition, carry out the stirring treatment of 6 minutes; Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com