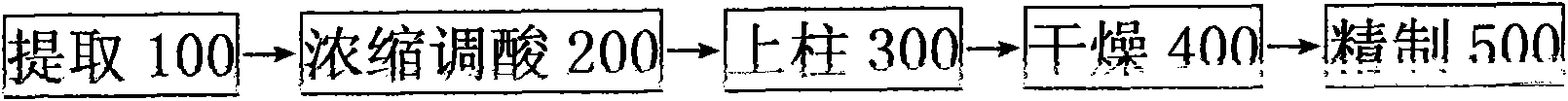

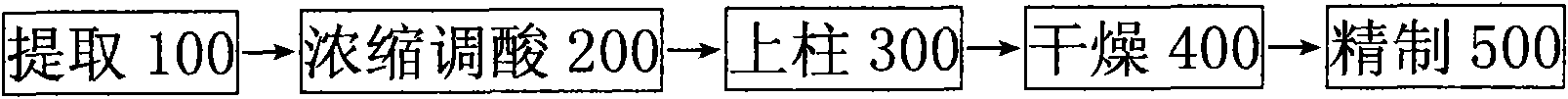

Production process of secoisolariciresinol diglucoside

A technology of flax lignans and production process, which is applied in the field of phytochemistry, and can solve the problems that cannot be directly applied to the column for adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] ①Crush flaxseed dregs, pass through a 100-mesh sieve, add 5 times the amount of 70% ethanol and 0.015 times the amount of 98% sodium hydroxide to the oil residue, and extract under reflux for 2 hours at a temperature of 80°C, and filter the extract with a suction filter bottle .

[0043] ② Concentrate the alkali-alcohol extract obtained in ① to a specific gravity of 1.05-1.1 and adjust the pH to 6.5 with acetic acid.

[0044] ③Put the concentrated solution adjusted in ② directly on the macroporous adsorption resin D101, wash the resin with purified water at 10°C, then elute with 20-50% ethanol, concentrate the eluent, and spray dry to obtain 40-60% flax Lignans.

[0045] ④ Dissolve the crude flax lignans obtained in ③ with 5 times the amount of acetone and stir for 1 hour, filter with suction, concentrate the filtrate, and spray dry to obtain 98% flax lignans.

Embodiment 2

[0047] ① Grind linseed medicinal residues, pass through a 20-mesh sieve, add 20 times the amount of 99.9% ethanol and 0.02 times the amount of 95% sodium hydroxide to the oil residues, and extract under reflux for 4 hours at a temperature of 70°C, and filter the extract with a suction filter bottle .

[0048] ② Concentrate the alkali-alcohol extract obtained in ① to a specific gravity of 1.05-1.1 and adjust the pH to 7 with hydrochloric acid.

[0049] ③Put the concentrated solution adjusted in ② directly on the macroporous adsorption resin AB-8, wash the resin with purified water at 5°C, then elute with 20-50% ethanol, concentrate the eluent, and spray dry to obtain 40-60% of flax lignans.

[0050] ④ Dissolve the crude flax lignans obtained in ③ with 5 times the amount of n-butanol and stir for 1 hour, filter with suction, concentrate the filtrate, and spray dry to obtain ≥97.3% flax lignans.

Embodiment 3

[0052] ①Crush the linseed medicinal residue, pass through a 40-mesh sieve, add 20 times the amount of 80% ethanol and 0.03 times the amount of 95% sodium hydroxide to the oil residue, and extract under reflux for 3 hours at a temperature of 80°C, and filter the extract with a suction filter bottle .

[0053] ② Concentrate the alkali-alcohol extract obtained in ① to a specific gravity of 1.05-1.1 and adjust the pH to 7 with sulfuric acid.

[0054] ③Put the concentrated solution adjusted in ② directly on the macroporous adsorption resin DM130, wash the resin with purified water at 20°C, then elute with 20-50% ethanol, concentrate the eluent, and spray dry to obtain 40-60% flax Lignans.

[0055] ④ Dissolve the crude flax lignans obtained in ③ with 5 times the amount of ethyl acetate and stir for 1 hour, filter with suction, concentrate the filtrate, and spray dry to obtain ≥98.6% flax lignans.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com