Plate-type membrane bioreactor

A technology of membrane bioreactor and bioreactor, which is applied in the direction of sustainable biological treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problems of low gas utilization rate and inability to ensure membrane plate gas flushing, etc., to achieve The flushing effect is obvious, the utilization rate is improved, and the effect of preventing the formation of the pollution layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

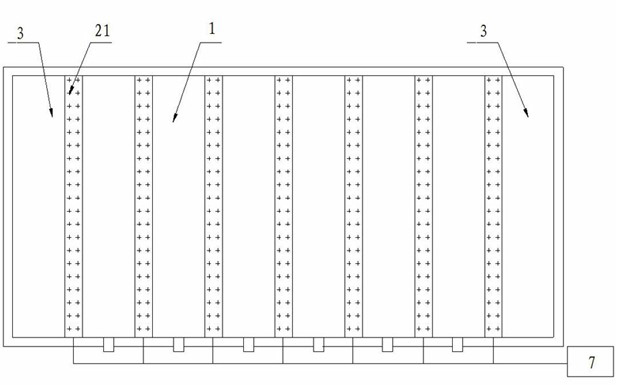

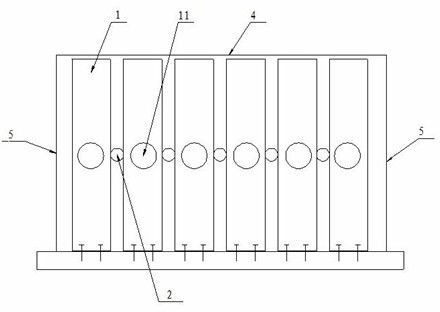

[0053] The plate type membrane bioreactor disclosed by the present invention is as figure 1 , figure 2Shown, comprise membrane support 6, described membrane support 6 is placed at the bottom of described membrane bioreactor, and apart from membrane bioreactor bottom 40cm; Sludge is relatively separated. The membrane plate assembly includes several regularly arranged membrane plates 1, and there is a distance between the adjacent membrane plates 1, and the distance between the upper end surface of the membrane plate assembly and the sewage upper surface of the membrane bioreactor is 40cm, so as to ensure filter effect. An aeration device is also included, and the aeration device includes an aeration tube 2 placed between adjacent membrane plates, and the axis of the aeration tube 2 is parallel to the upper and lower end surfaces of the membrane plates 1 . The aeration pipe 2 communicates with a gas generator 7; the gas generator 7 in this embodiment is an aeration pump.

...

Embodiment 2

[0062] This embodiment is another embodiment of the present invention, such as image 3 , Figure 4 Shown, comprise membrane support 6, described membrane support 6 is placed on the bottom of described membrane bioreactor and apart from membrane bioreactor bottom 30cm; The mud is relatively separated. The membrane plate assembly includes several regularly arranged membrane plates 1, and there is a distance between adjacent membrane plates 1, and the distance between the upper end surface of the membrane plate assembly and the sewage upper surface of the membrane bioreactor is 30 cm, so as to ensure filter effect. An aeration device is also included, the aeration device includes an aeration tube 2 placed between adjacent membrane plates and the bottom is flush with the bottom surface of the membrane plate, and the aeration tube 2 communicates with the gas generating device 7; The gas generating device described in this embodiment is an aeration pump.

[0063] Two rows of ae...

Embodiment 3

[0075] This embodiment is another implementation of the plate membrane bioreactor, such as Figure 5 shown. The structure of this embodiment is generally consistent with the structure described in Embodiment 1, the difference lies in the position of the aeration tube and the aeration holes on the aeration tube. Specifically:

[0076] The aeration tube 2 is placed between the adjacent membrane plates, its axis is parallel to the upper and lower end surfaces of the membrane plates 1 , and the distance from the upper and lower end surfaces of the membrane plates 1 is equal. The upper pipe wall of the aeration pipe 2 is provided with several irregularly arranged aeration holes 21 of different sizes, and the gas ejected from the aeration holes 21 forms a gas that directly acts on the surface of the membrane plate. For flushing the water flow, the angle between the air outlet direction of the aeration hole 21 and the surface of the membrane plate is 20-80 degrees.

[0077] The ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com