Method and device for controlling the pressure inside a fuel tank

A technology of internal pressure and fuel tank, applied in power plant, layout, transportation and packaging combined with internal combustion engine fuel supply, etc., can solve problems such as unfavorable activated carbon filter uniform adsorption and separation of fuel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

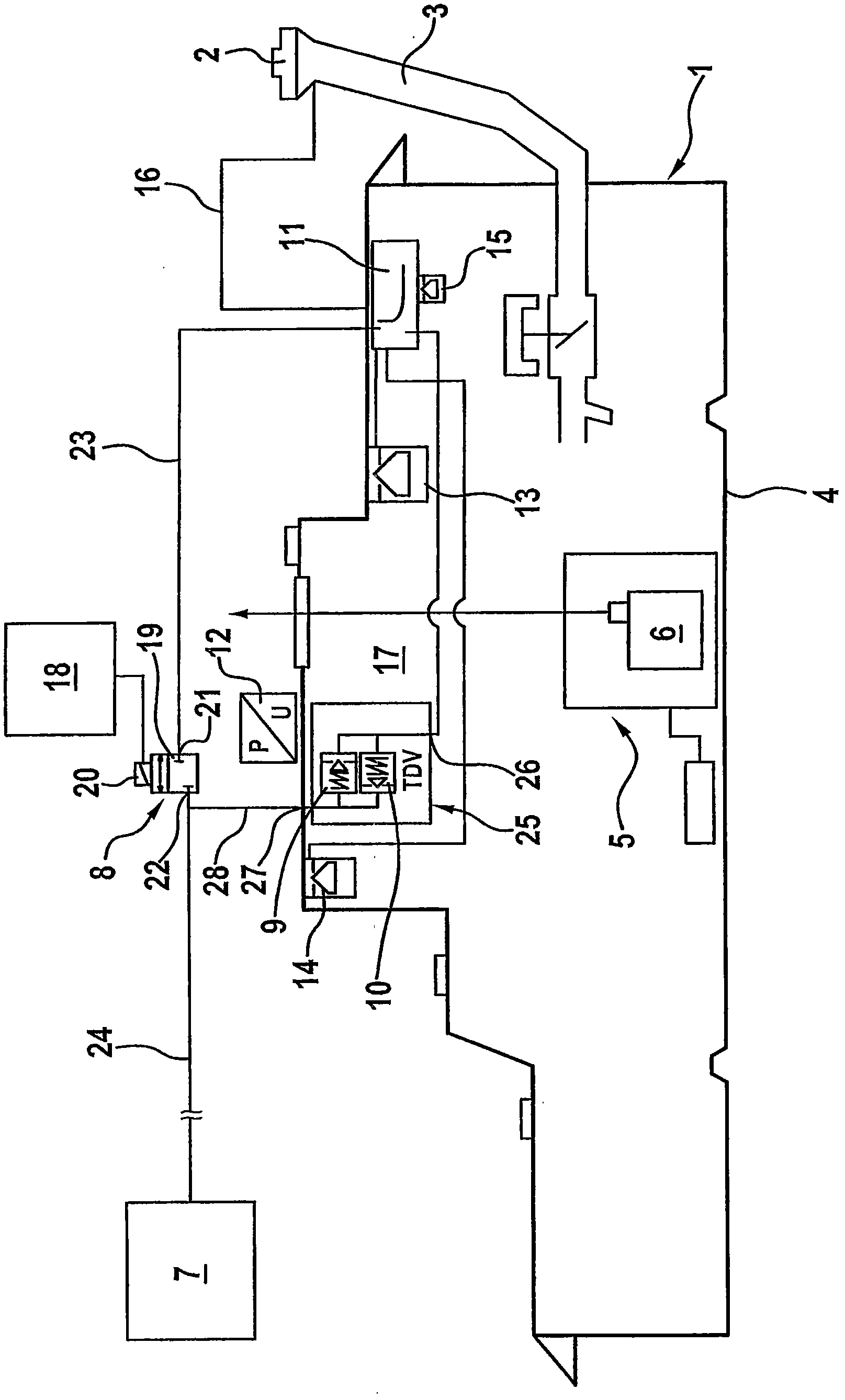

[0025] The fuel tank 1 for a motor vehicle shown in the drawings is a sealed fuel tank 1 made of an airtight and liquid-tight interlayer material by blow molding. For filling, the fuel tank 1 has a filler pipe 3 which can be closed by a fuel tank cap 2 . Near the bottom 4 of the fuel tank 1 there is a supply unit 5 with a fuel pump 6 immersed in the fuel.

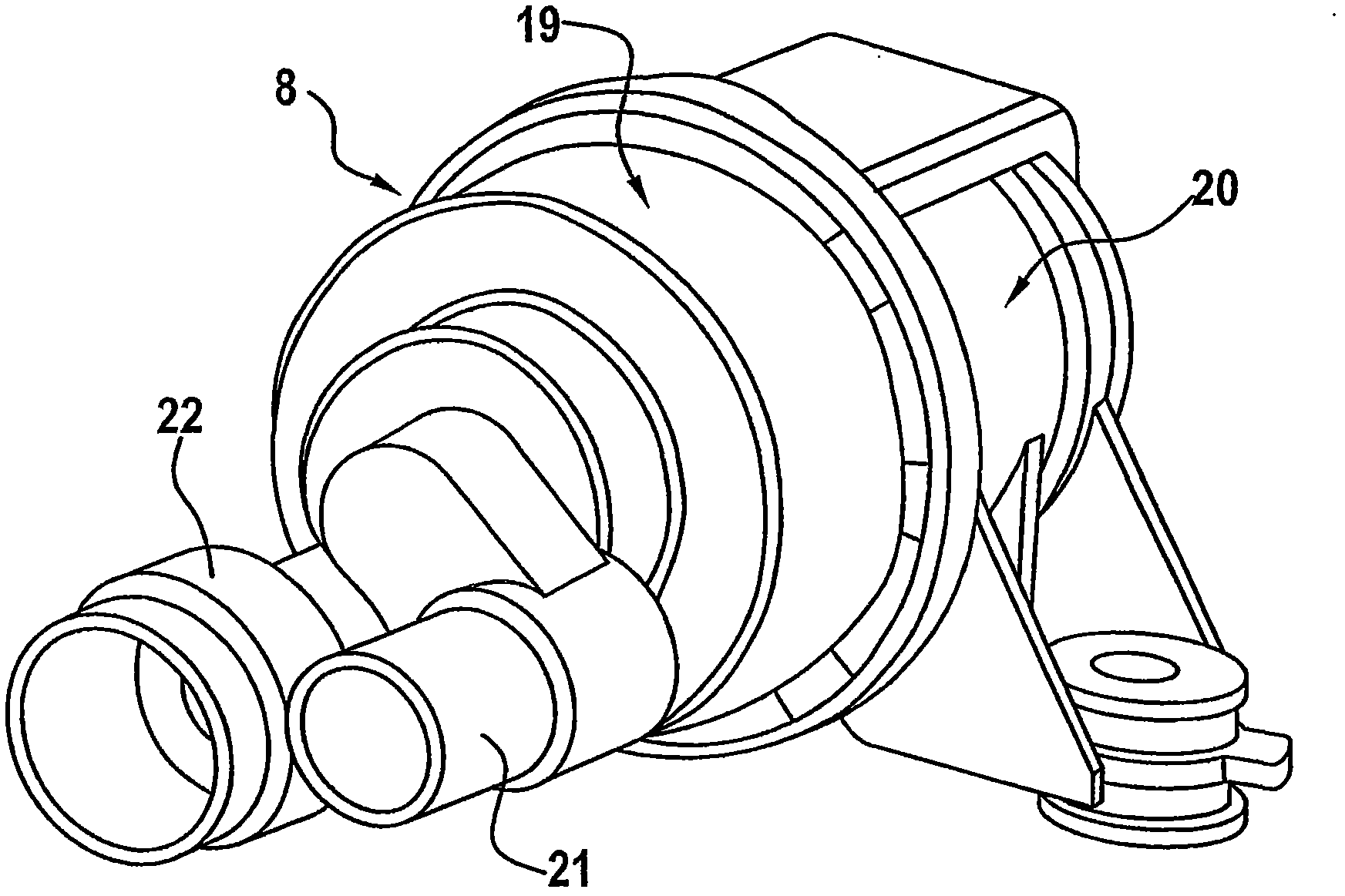

[0026] The fuel tank 1 is equipped with a ventilation and ventilation device, by means of which the pressure inside the fuel tank 1 can also be controlled. Ventilation and ventilation unit including activated carbon filter 7, fuel tank shut-off valve 8, two fuel tank pressure regulator valves 9 and 10, liquid trap 11, fuel tank pressure sensor 12 and multiple rollover safety valves 13, 14, 15 . The liquid trap 11 arranged in the gas space or the head space of the fuel tank 1 adjacent to the upper side of the fuel tank 1 shall prevent the mixed gas flowing from the inside of the fuel tank 1 when the fuel tank 1 is ventilat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com