Calendering shaping device for polyethylene glycol terephthalate (PET) nano reinforced plate production line

A shaping device and strengthening board technology, which is applied in the field of calendering shaping devices, can solve the problems of affecting the quality of PET board products and not being able to obtain heat, and achieve the effect of improving shaping quality, increasing heating effect, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

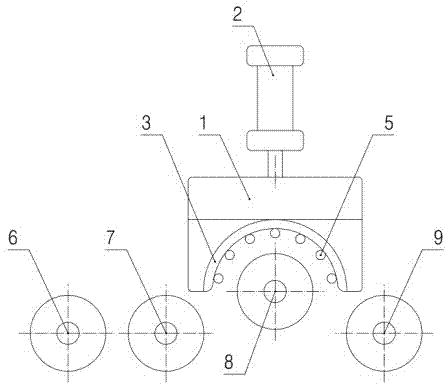

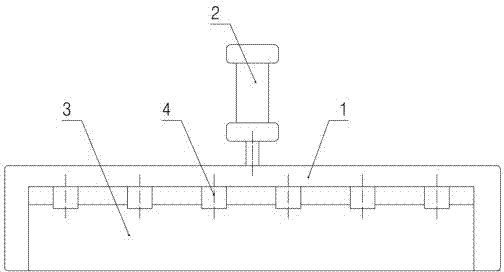

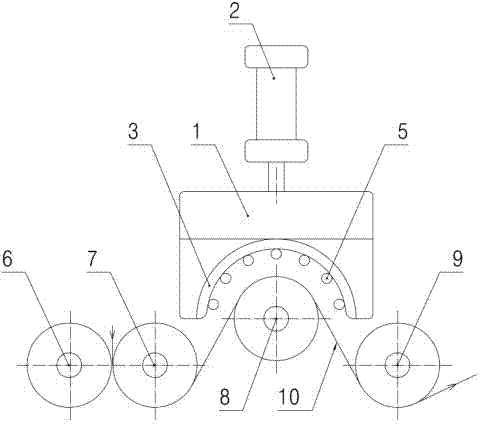

[0017] Such as figure 1 As shown, a calendering and setting device for a PET nano-reinforced board production line includes a frame (which belongs to the usual technology in the art, not shown in the figure), and a pair of cooling calender rollers 6 parallel to each other are sequentially arranged on the frame And 7 and front sizing heating roll 8 and rear sizing heating roll 9, front sizing heating roll 8 and cooling calender roll 6 and 7 and rear sizing heating roll 9 are all staggered mutually in vertical direction, on the frame before sizing heating roll 8 A sizing heating device matched with the front sizing heating roller 8 is arranged above the top of the sizing heating device, and the specific structure of the sizing heating device includes a bracket 1, and an arc-shaped casing 3 matched with the front sizing heating roller 8 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com