Self-centering of Worktable and Control Method of Workpiece Clamping Device

The technology of a clamping device and a control method is applied in the field of workbench self-centering and workpiece clamping device and its control, which can solve the problems of high purchase cost, low clamping efficiency, injury to operators, etc., and achieve simple structure of the device, Stable and reliable performance, the effect of improving clamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

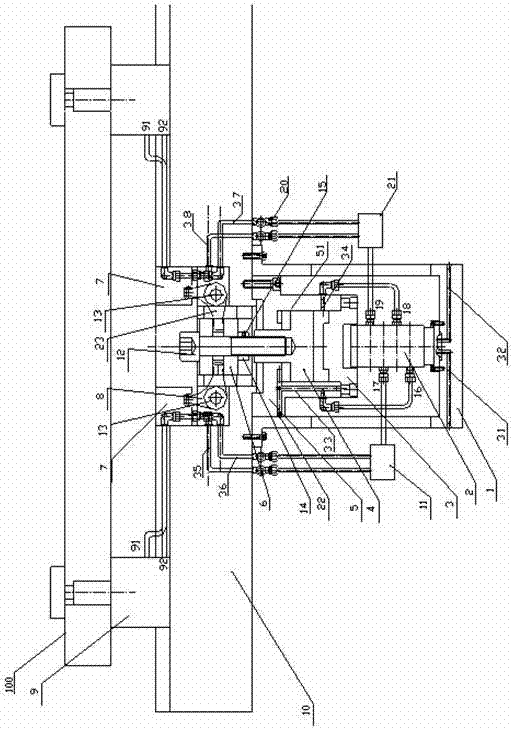

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The specific embodiments described here are only used to explain the present invention, and are not used to limit the protection scope of the present invention.

[0039] combined reference figure 1 The shown workbench 10 self-centering and workpiece clamping device specifically includes a workbench 10; a fixed support 1 is fixed under the workbench 10 and remains concentric with the workbench 10, and the fixed support 1 The first oil passage 31 and the second oil passage 32 are arranged in it; the integrated solenoid valve 2 is arranged at the bottom of the fixed bracket 1 involved, and the integrated solenoid valve 2 includes a first oil outlet 16, a second oil outlet 17, The third oil outlet 18, the fourth oil outlet 19 and two oil inlets ( figure 1 unmarked), the two oil inlets are respectively connected to the first oil passage 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com