Guide arc current circuit for plasma cutting power supply

A technology of current circuit and pilot arc, which is applied in the field of ion cutting power supply, can solve the problems of waste of ferromagnetic materials and conductor materials in the main circuit, damage to personal and equipment safety, high-frequency interference, etc., achieve saving and conductor materials, and improve The success rate of arc striking and the effect of reducing high-frequency interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

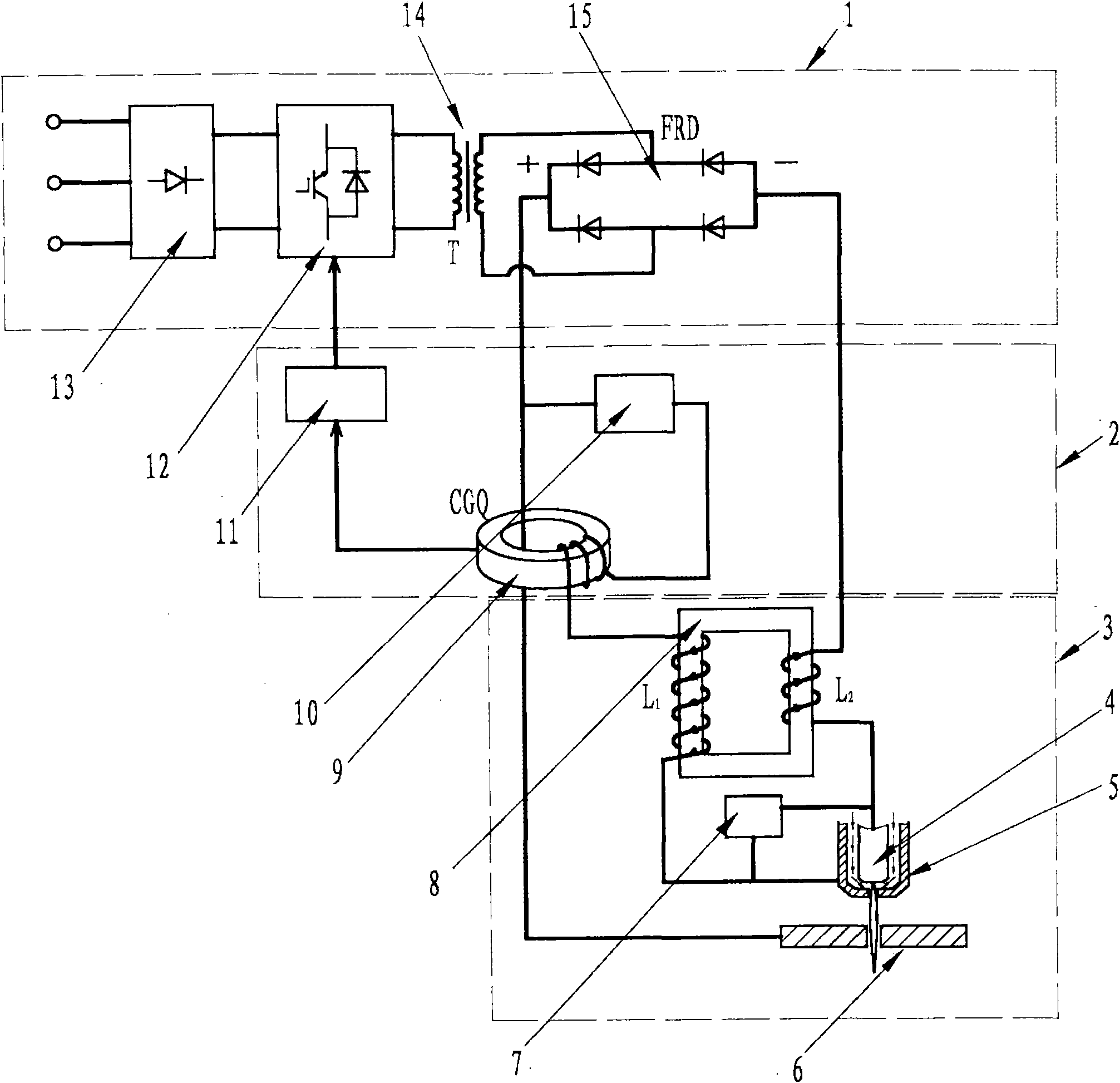

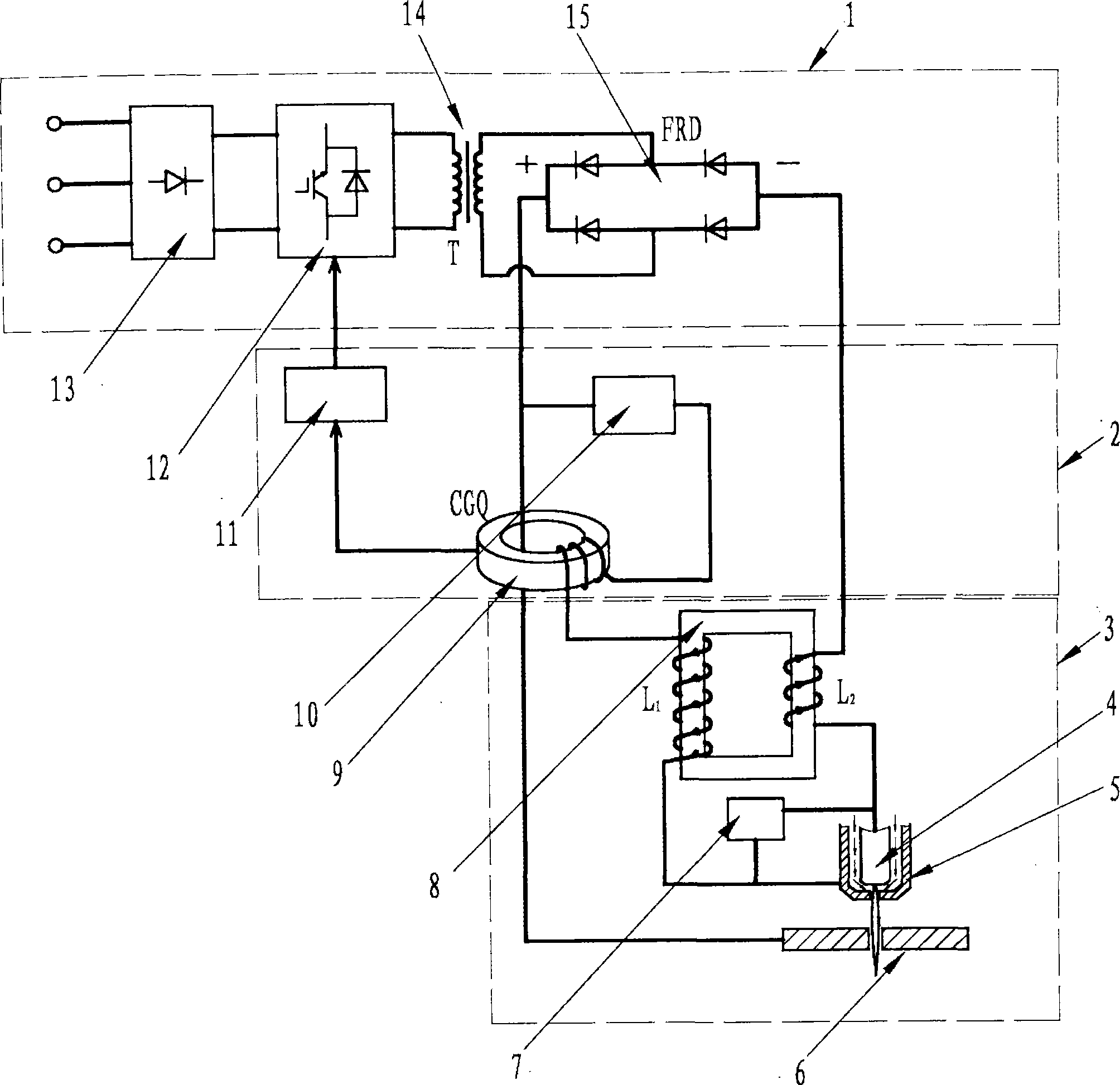

[0013] figure 1 The circuit principle diagram of the present invention is given. The plasma pilot arc current circuit of the plasma cutting power supply includes three parts: the inverter and rectification output circuit (1), the pilot arc and cutting arc control circuit (2), and the pilot arc freewheeling circuit (3).

[0014] The inverter and rectification circuit (1) includes a three-phase input rectification circuit (13), an IGBT inverter bridge circuit (12), an intermediate frequency transformer (14), an FRD fast recovery rectification output circuit (15), an IGBT inverter The input terminal of the variable bridge circuit (12) is connected to the three-phase input power supply through the three-phase input rectifier circuit (13), the output terminal of the IGBT inverter bridge circuit is connected to the primary winding of the intermediate frequency transformer (14), and the secondary winding of the intermediate frequency transformer (14) The primary winding is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com