Blending device

A technology of mixed gas and gas mixer, which is applied in the direction of mixer, mixing method, gas and gas/steam mixing, etc. It can solve the problems of small mixing capacity, low mixing precision, and inability to adjust, and achieve high mixing precision , the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

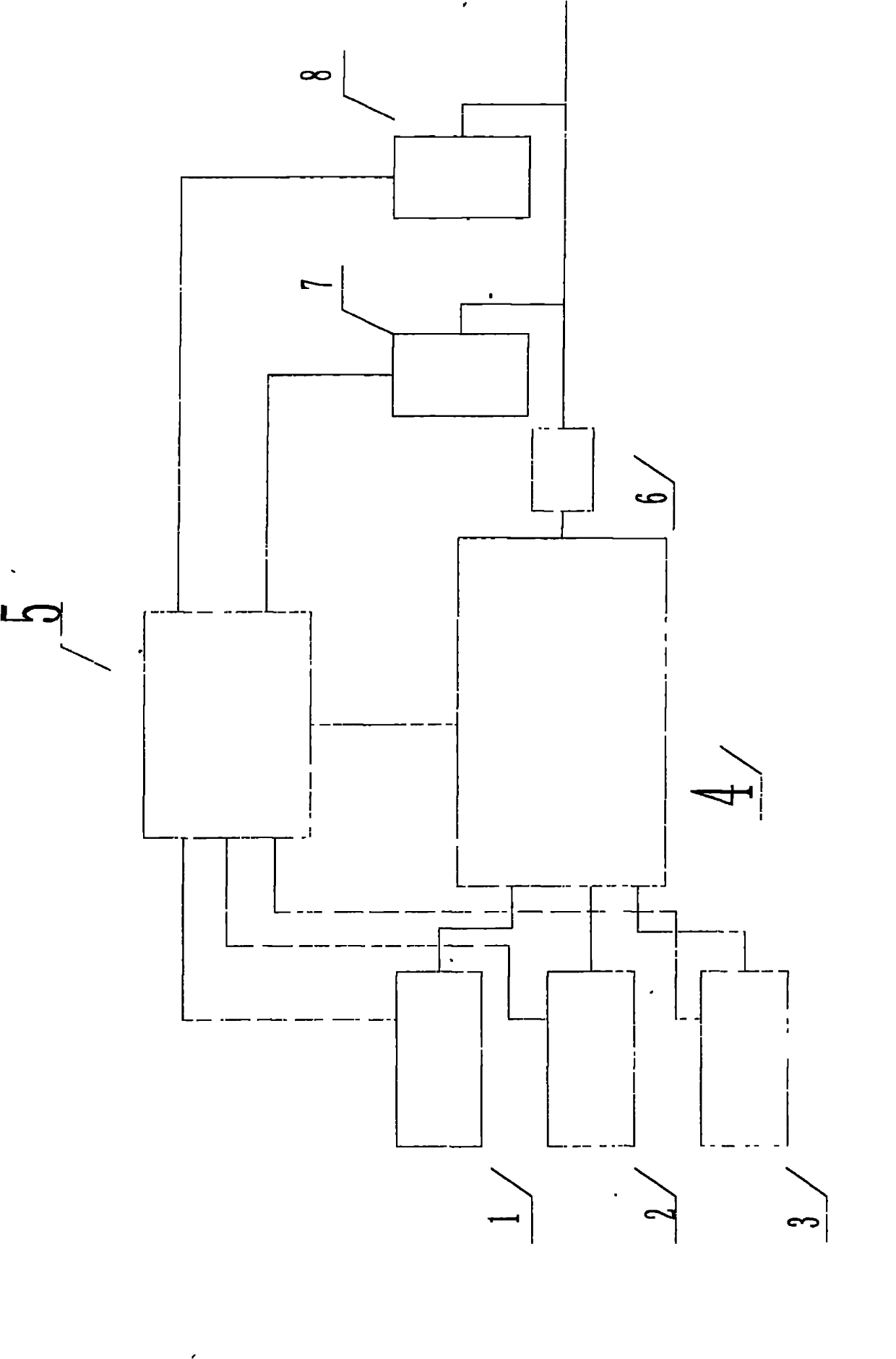

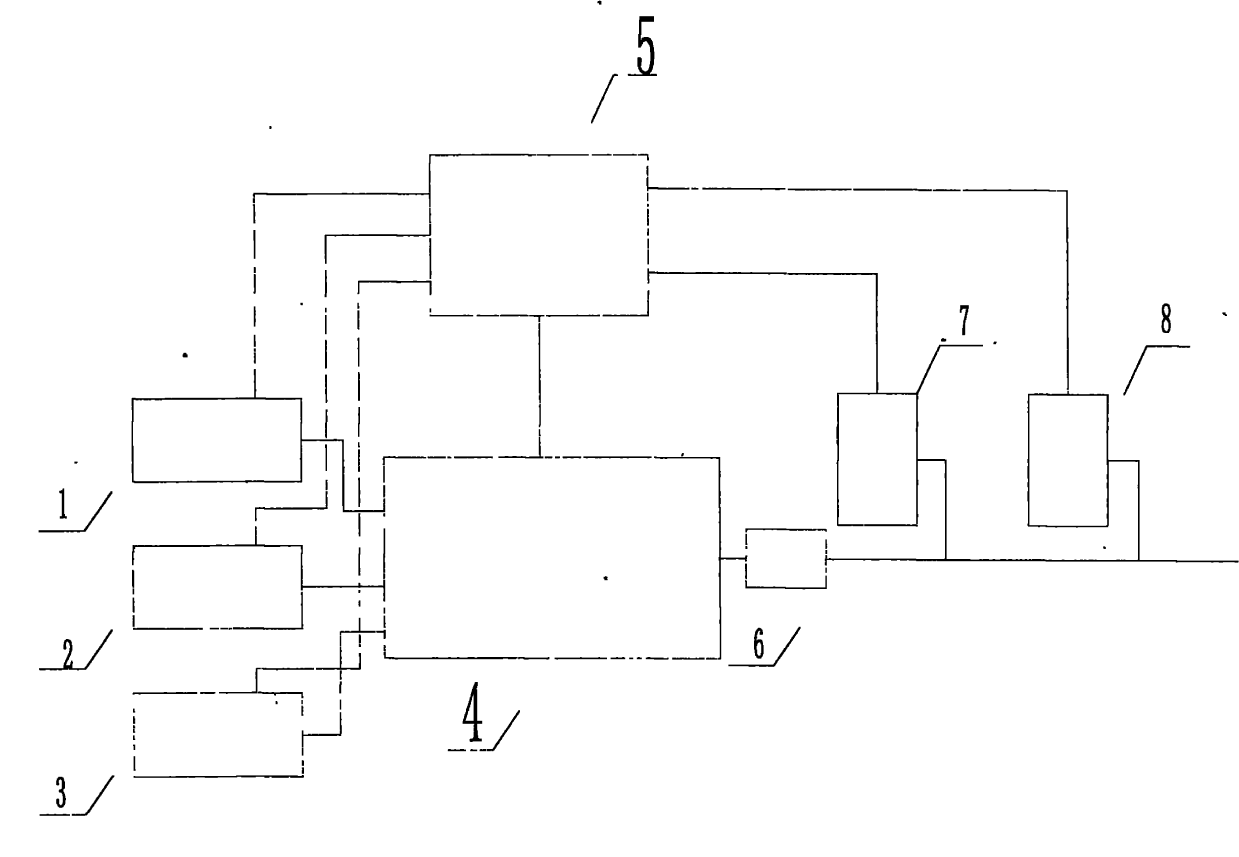

[0008] A coalbed methane device, including a low-concentration coalbed methane pipeline 1, a high-concentration coalbed methane pipeline 2, an air pipeline 3, a gas mixer 4, a controller 5, a mixed gas pipeline 6, an oxygen analyzer 7, a calorific value instrument 8, and a gas One side of the mixer 4 is respectively connected to the low-concentration coalbed methane pipeline 1, the high-concentration coalbed methane pipeline 2, and the air pipeline 3; the other side of the gas mixer 4 is connected to the mixed gas pipeline 6; 1. High-concentration coalbed methane pipeline 2, air pipeline 3, and gas mixer 4 are connected, and gas mixer 4 and controller 5 are connected to oxygen analyzer 7 and calorific value instrument 8 respectively.

[0009] According to the consideration of the pressure of the incoming air pipeline, it is more reasonable to choose the method of boosting first and then mixing. The compressed air is first boosted to 0.5-0.7MPa with an air compressor, and then d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com