Rootstock opening-cleaving device and application thereof

A rootstock and splitting technology, applied in the field of plant reproduction, can solve the problems of difficult to guarantee grafting quality, cut fingers, increase costs, etc., and achieve the effects of improving work efficiency and success rate, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

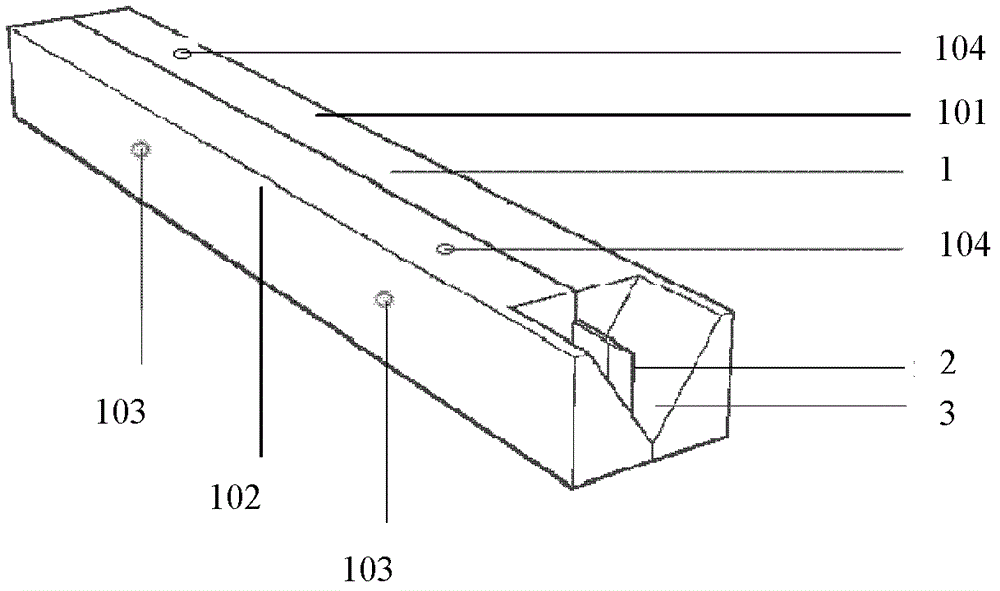

[0015] combine figure 1 The rootstock splitting device of the present invention is described in detail.

[0016] figure 1 The rootstock splitting device shown includes a detachable main body 1 and a blade 2, wherein the main body 1 includes main bodies a101 and b102, and the main bodies a101 and b102 are clamped by a clamping device 103, and one end of the detachable main body 1 is provided with A "V"-shaped groove 3, the blade 2 is located in the middle of the "V"-shaped groove 3.

[0017] In this embodiment, the clamping device 103 is a tightening screw, which can disassemble the main body 1 and the blade 3 and adjust the position of the blade 3 .

[0018] In this embodiment, the main bodies a101 and b102 are hardwood, and the "V" shaped groove 3 is coated with iron sheet to increase its wear resistance and smoothness.

[0019] In this embodiment, the rootstock splitting device is fixed on the operating table by a fixing device (104), specifically a fixing screw.

Embodiment 2

[0021] The rootstock splitting device of the present embodiment is basically the same as embodiment 1, except that what is coated on the "V" shape groove 3 is copper skin.

Embodiment 3

[0022] Embodiment 3 Grape rootstock grafting

[0023] Put the grafted end of the grape rootstock at the "V"-shaped groove 3 of the rootstock splitting device in Example 1, push the grafted end against the splitting blade 2, and gently push the grafted end of the rootstock to the "V"-shaped groove 3, the blade 2 automatically splits a kerf in the middle of the grafted end of the rootstock, and takes it down and puts it aside for subsequent use;

[0024] Use a scion cutter to cut the grafted end of the scion into a flat wedge shape on both sides, insert the prepared scion along the cut of the rootstock so that the cambium on the eye side of the scion is aligned with the cambium on the same side of the rootstock, and finally cover it with a strip of plastic film Firmly hold the grafted parts of the scion and rootstock, and the grafting operation can be completed.

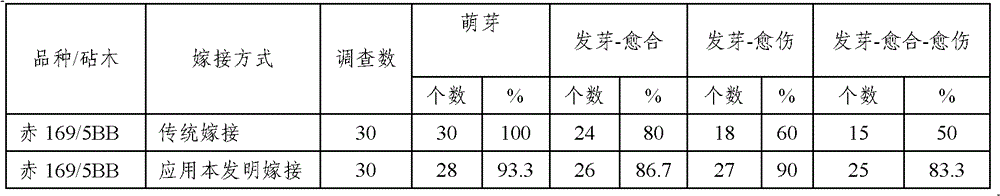

[0025] Compared with the traditional grafting method, the application rate of the present invention is doubled, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com