Dust collection device of grass cutter

A technology of dust removal device and grass cutter, which is applied in cutting equipment, agricultural machinery and implements, applications, etc., can solve the problems of dust, environmental pollution, and unhealthy livestock.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

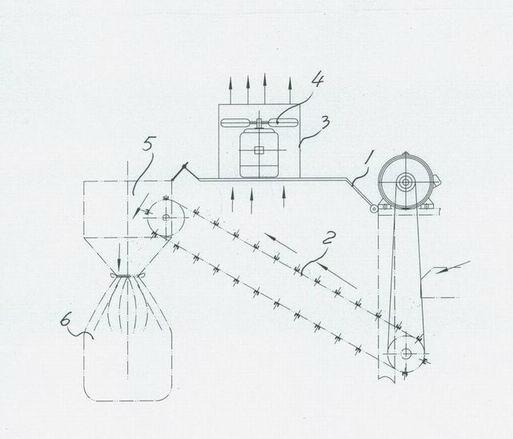

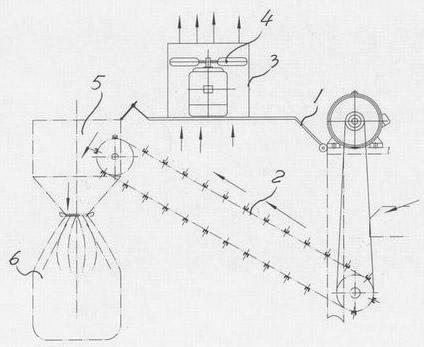

[0005] One embodiment of the present invention is, existing forage grass cutting machine has cutting grass roller and grass bucket 5 and the conveyer belt 2 between the grass outlet of grass cutting roller and the grass bucket, in order to solve the contained content of the good forage grass of processing Dust, on the sealed casing 1 above the above-mentioned conveyor belt 2, an outlet box 3 is provided, and an exhaust fan 4 is arranged in this outlet box.

[0006] The working principle of the present invention is that during the conveying process of the forage grass cut by the grass cutting roller, the exhaust fan draws air outwards to form a negative pressure above the conveyor belt, and the dust in the forage grass on the conveyor belt is discharged outside the machine by the exhaust fan, including The few forage grass of dust falls in the straw bag 6 from the outlet of receiving hopper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com