Aluminum ribbon for ultrasonic bonding

A technology of ultrasonic welding and aluminum strip, applied in thin material processing, semiconductor devices, electrical components, etc., can solve problems such as difficult bonding, fracture of aluminum strip, balance damage of welding conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

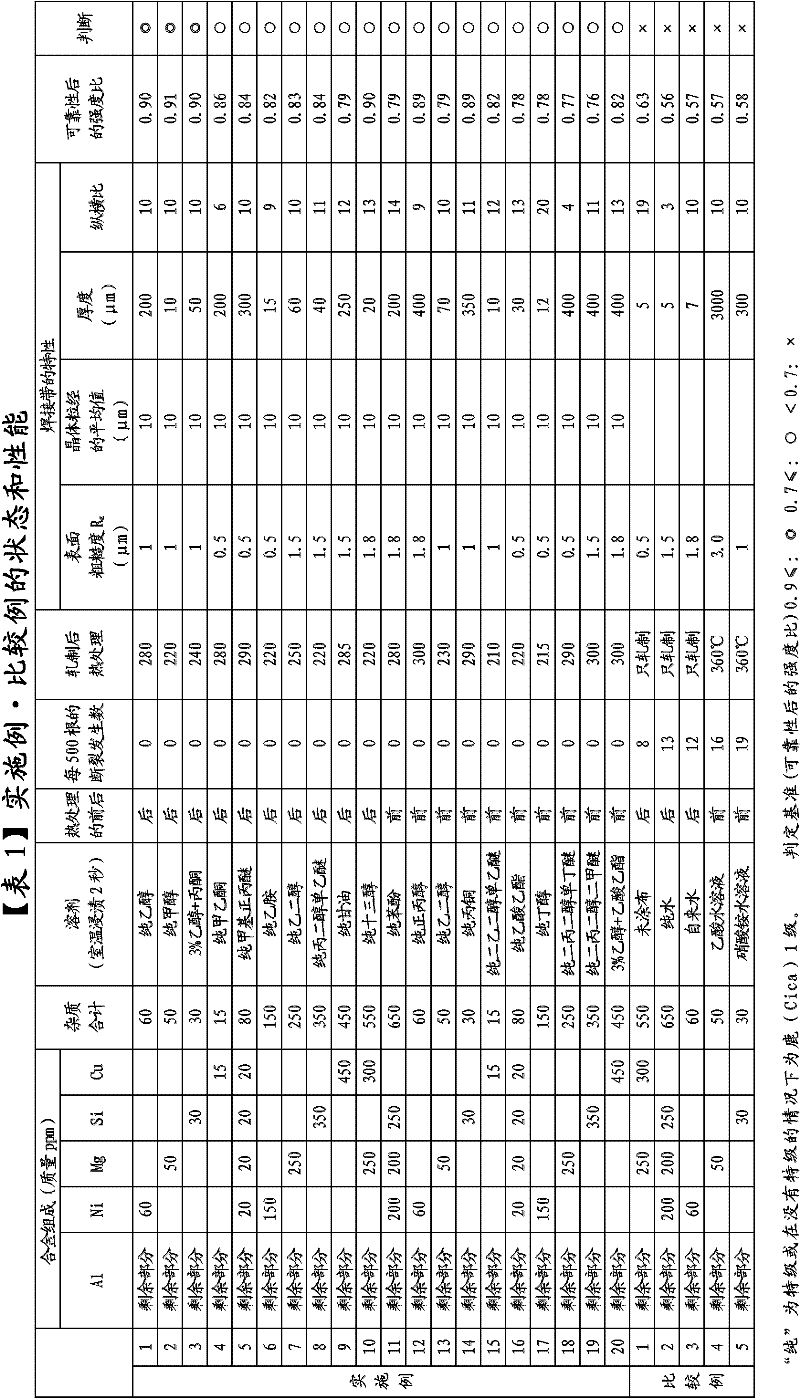

[0060] Next, examples of the present invention will be described.

[0061] The alloy composition shown in Table 1 (Although aluminum (Al) with a purity of 99.999% by mass was used as the raw material for preparation, the same result was obtained for aluminum (Al) with a purity of 99.99% by mass.) and a welding wire with a specified wire diameter was used to produce As a hair material, Examples 1-20 and Comparative Examples 1-5 of the welding tape shown in Table 1 were prepared. These welded strips were obtained by performing a one-stage heat treatment rolling process using a rolling device (not shown), and dipping them in a high-purity ethanol solution for 2 seconds before or after heat treatment at a predetermined temperature shown in Table 1. Welding strips.

[0062] Examples 1 to 20 and Comparative Examples 1 to 5 of the present invention thus obtained were ultrasonically welded to an Al plate (thickness 5 mm) with a purity of 99.99% by mass under the following number and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com