Electric motor and vehicle drive device using the same

A technology of electric motors and assemblies, which is applied in the field of vehicle drive devices and electric motors, and can solve problems such as temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

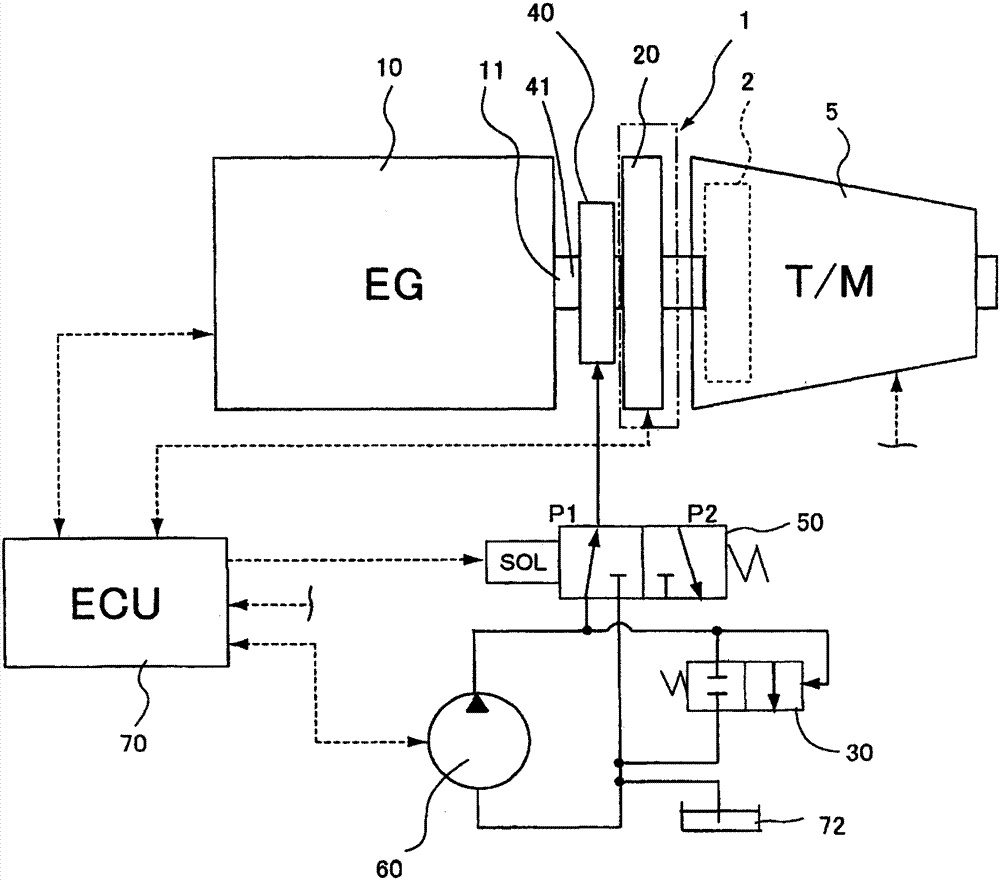

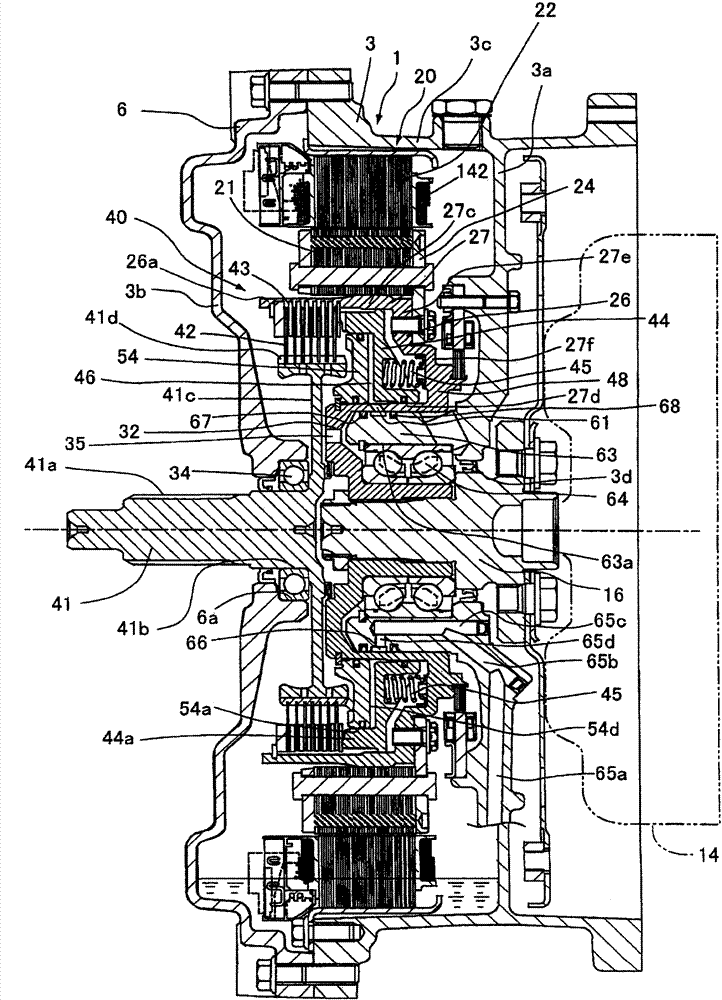

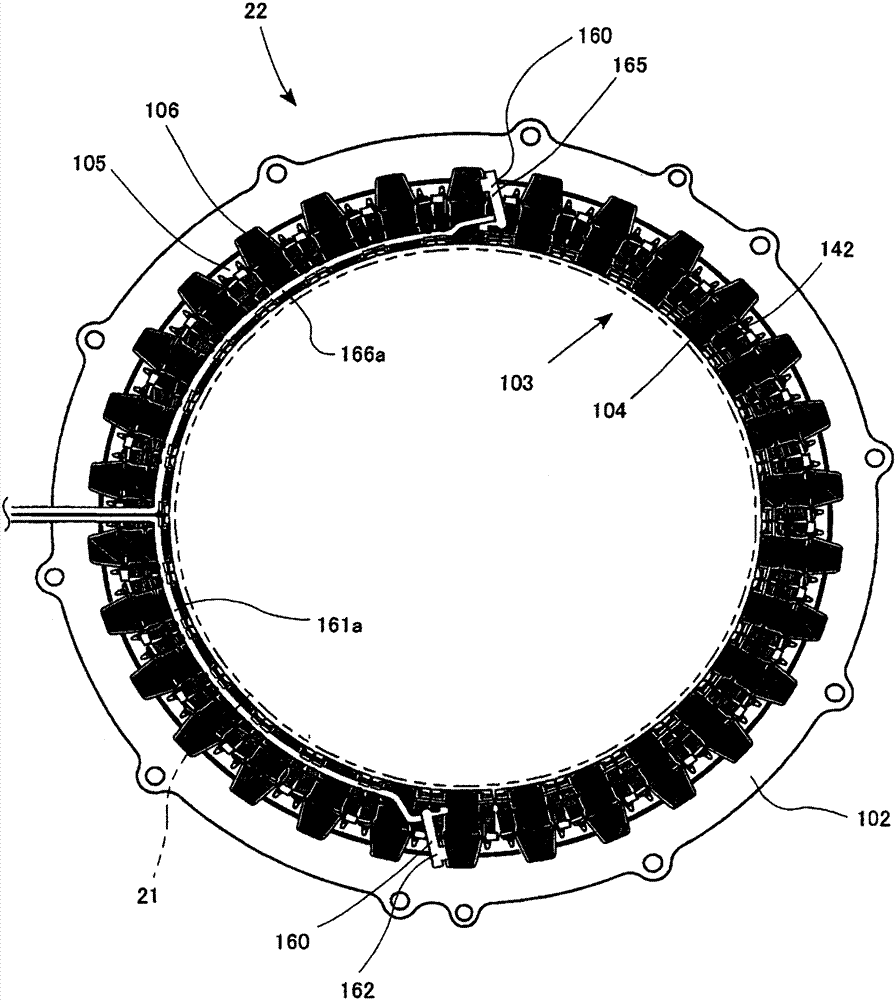

[0042] Hereinafter, embodiments according to the present invention will be described with reference to the drawings embodied as a hybrid vehicle. figure 1 A schematic diagram showing a hybrid vehicle drive system using the electric motor 20 according to the present invention and the vehicle drive device 1 using the electric motor 20 . In addition, if figure 2 As shown, the drive device 1 for a vehicle is composed of a casing 3, an output shaft 26, and an electric motor 20, wherein the output shaft 26 is pivotally supported on the casing 3 so as to be rotatable around a rotation axis, and the electric motor 20 has a rotor 21 integrally rotating Combined with the output shaft 26 , the stator 22 opposite to the rotor 21 is fixed on the housing 3 .

[0043] exist figure 1 In , the arrows of the solid line indicate the hydraulic piping connecting each device, and the arrows of the broken line indicate the signal lines for control. In addition, in figure 1 In the figure, the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com