Self-starting permanent magnet synchronous motor rotor adopting conductive sleeve

A technology of permanent magnet synchronous motor and conductive sleeve, which is applied to the rotating parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc. It can solve the problems of affecting the distribution of the air gap magnetic field, large torque pulsation components, and motor vibration, etc., to achieve Effects of reducing eddy current loss and stray loss, large asynchronous starting torque, and suppressing running noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

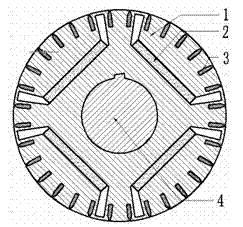

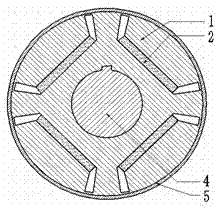

[0018] refer to figure 2 , the self-starting permanent magnet synchronous motor rotor using a conductive sleeve includes an iron core 1, a permanent magnet 2, a shaft 4 and a conductive sleeve 5, wherein the permanent magnet 2 is embedded in the iron core 1, the iron core 2 is installed outside the shaft 4, and the conductive sleeve 5 is wrapped On the outside of the rotor core 1, a rotor starting winding is formed. The material of the conductive sleeve 5 is copper, aluminum alloy or stainless steel.

[0019] The conductive sleeve 5 fixes the conductive sleeve and the rotor core by means of interference fit, glue, pins and the like.

[0020] The asynchronous starting torque is provided during the starting stage of the motor, which improves the starting ability of the motor. When the motor is running in a steady state, the rotor speed is at synchronous speed, and the eddy current in the conductive sleeve is small, which has little impact on the steady-state running performanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com