Nanometer perovskite/graphene composite material and preparation method thereof

A composite material and graphene technology, applied in the field of electrocatalytic materials, can solve the problems of reducing the specific capacity of the battery, deteriorating the conductive properties of activated carbon, and reducing the performance of the battery, and achieve the effects of improving utilization efficiency, low cost, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

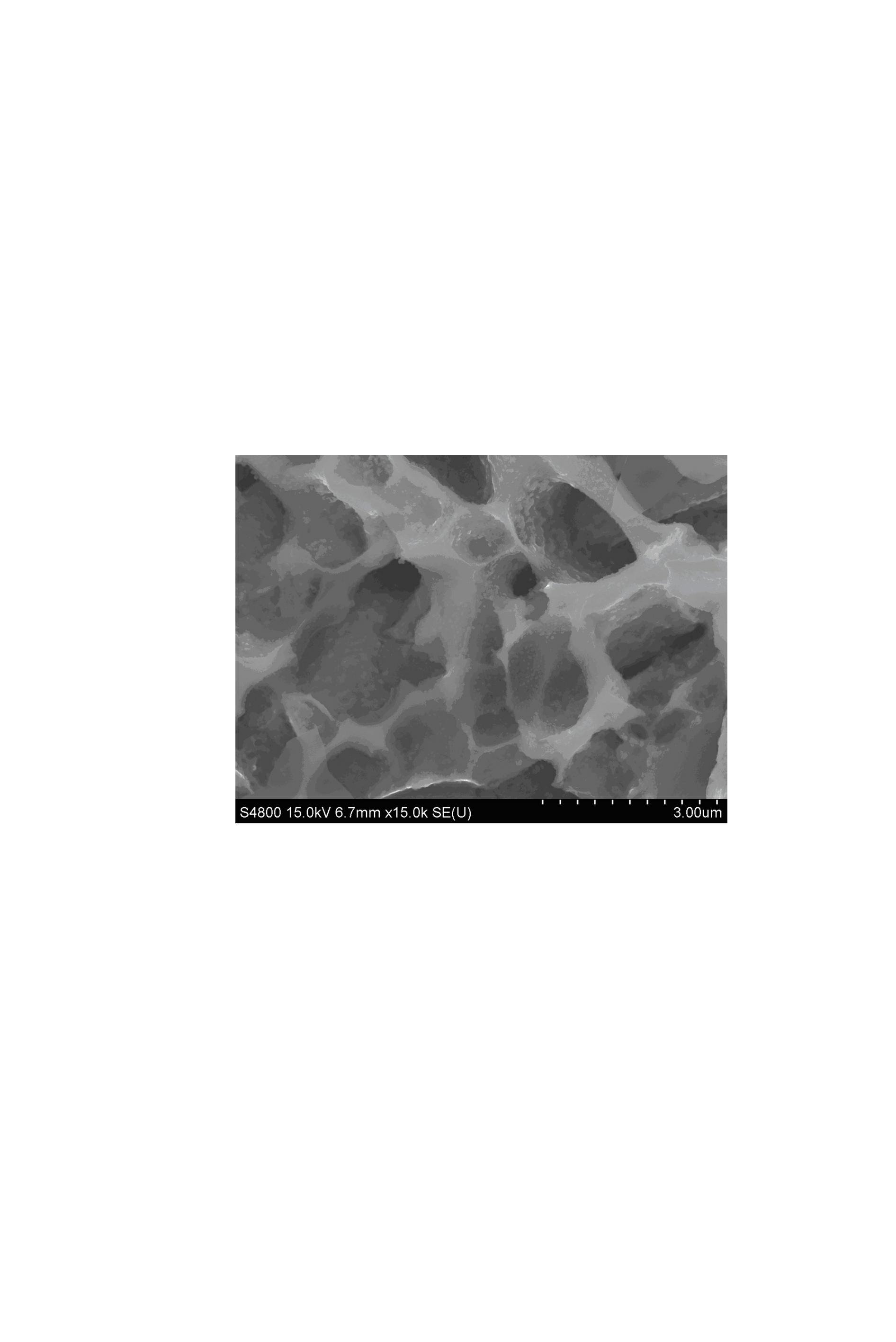

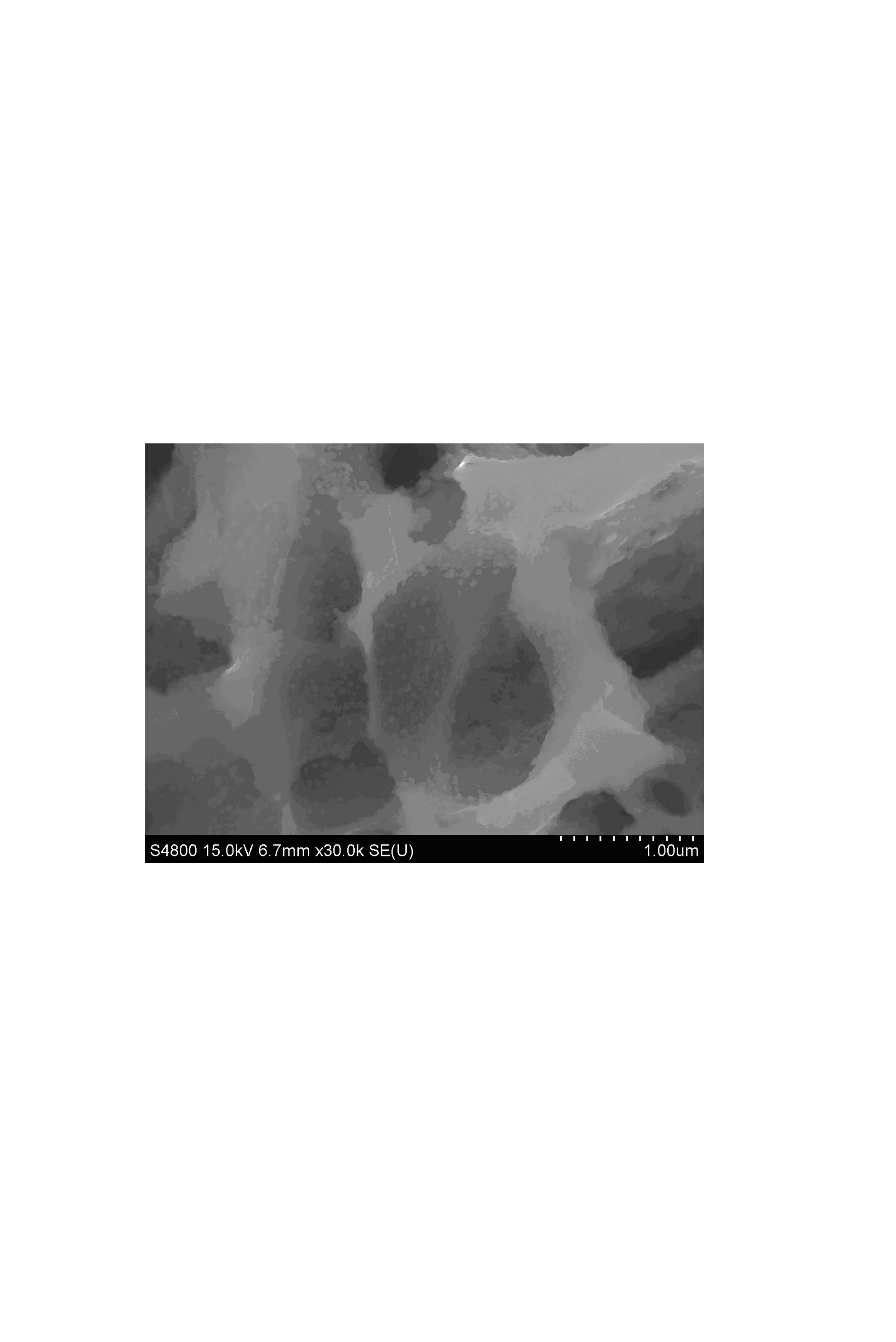

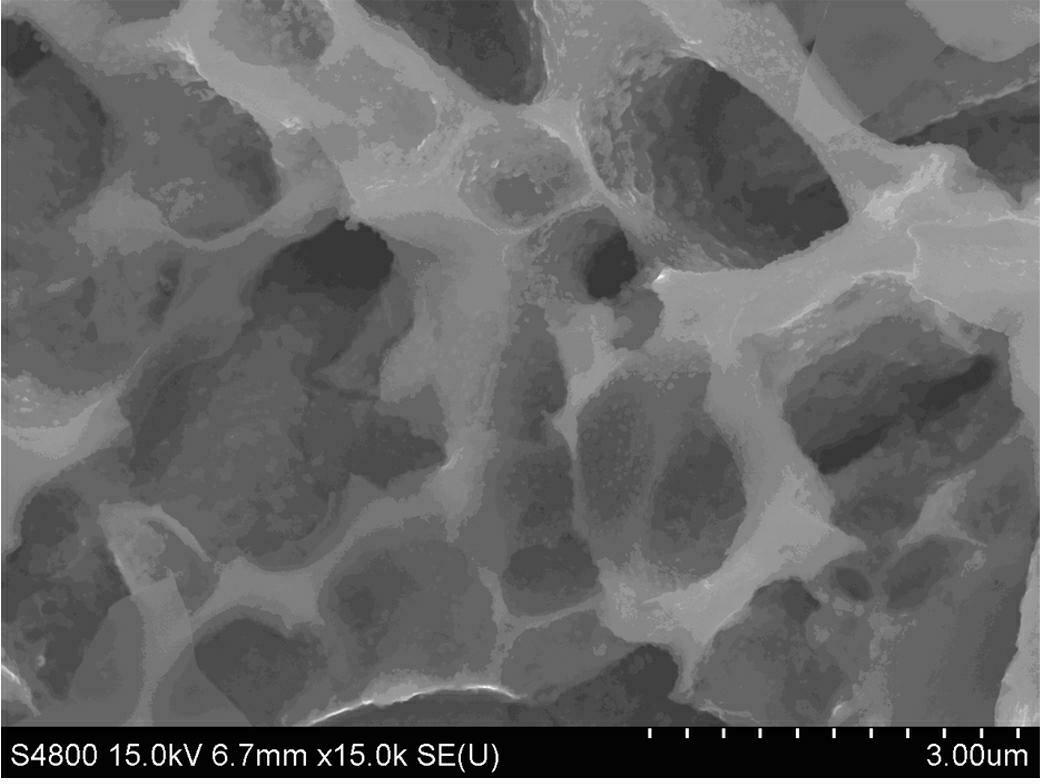

Image

Examples

Embodiment 1

[0017] Using graphite paper as the anode, carbon rod as the cathode, and concentrated sulfuric acid (98% concentration) as the electrolyte, the graphite paper is oxidized and peeled off at a constant current of 0.2A. After stripping for 24 hours, the electrolyte solution was diluted 10 times with distilled water, and after the solution was cooled to room temperature, it was separated and filtered by a high-speed centrifuge at 12,000 rpm. The filtered powder was fully washed with distilled water until neutral, and dried at 50°C under a vacuum of 100 Pa to obtain a graphene oxide powder. Take 100 mg of the powder and add it into 100 mL of distilled water, and adjust its pH to 10 with ammonia water. Sonicate for 3 h at a power of 150 W to obtain a stable graphene oxide suspension. Add 1.5 mL of hydrazine hydrate dropwise to the above suspension, heat it in a constant temperature water bath at 80oC for 10h, wash the reactant until neutral, and dry it at 50oC under a vacuum of 100...

Embodiment 2

[0021] Using graphite paper as the anode, carbon rod as the cathode, and concentrated sulfuric acid (98% concentration) as the electrolyte, the graphite paper is oxidized and peeled off at a constant current of 0.2A. After stripping for 24 hours, the electrolyte solution was diluted 10 times with distilled water, and after the solution was cooled to room temperature, it was separated and filtered by a high-speed centrifuge at 12,000 rpm. The filtered powder was fully washed with distilled water until neutral, and dried at 50°C under a vacuum of 100 Pa to obtain a graphene oxide powder. Take 100 mg of the powder and add it into 100 mL of distilled water, and adjust its pH to 10 with ammonia water. Sonicate for 3 h at a power of 150 W to obtain a stable graphene oxide suspension. Add 1.5 mL of hydrazine hydrate dropwise to the above suspension, heat it in a constant temperature water bath at 80oC for 10h, wash the reactant until neutral, and dry it at 50oC under a vacuum of 100...

Embodiment 3

[0025] Using graphite paper as the anode, carbon rod as the cathode, and concentrated sulfuric acid (98% concentration) as the electrolyte, the graphite paper is oxidized and peeled off at a constant current of 0.2A. After stripping for 24 hours, the electrolyte solution was diluted 10 times with distilled water, and after the solution was cooled to room temperature, it was separated and filtered by a high-speed centrifuge at 12,000 rpm. The filtered powder was fully washed with distilled water until neutral, and dried at 50°C under a vacuum of 100 Pa to obtain a graphene oxide powder. Take 100 mg of the powder and add it into 100 mL of distilled water, and adjust its pH to 10 with ammonia water. Sonicate for 3 h at a power of 150 W to obtain a stable graphene oxide suspension. Add 1.5 mL of hydrazine hydrate dropwise to the above suspension, heat it in a constant temperature water bath at 80oC for 10h, wash the reactant until neutral, and dry it at 50oC under a vacuum of 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com