Optical diffusion film and preparation method thereof

A technology of optical diffusion and diffusion film, which is applied to chemical instruments and methods, flat products, and other household appliances, etc., can solve problems such as poor adhesion and complicated process, and achieve environmental protection, good comprehensive performance, and improved adhesion. The effect of knot strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of the optical diffusion film provided by the invention comprises the following steps:

[0052] (1) Preparation of scattering masterbatch

[0053] Mix the calculated amount of scattering particles and polyester chips evenly so that the weight content of scattering particles in the masterbatch is 4g-8g / kg, preferably 6g / kg (6000ppm), and then melt, extrude, and pelletize to obtain scattering masterbatch;

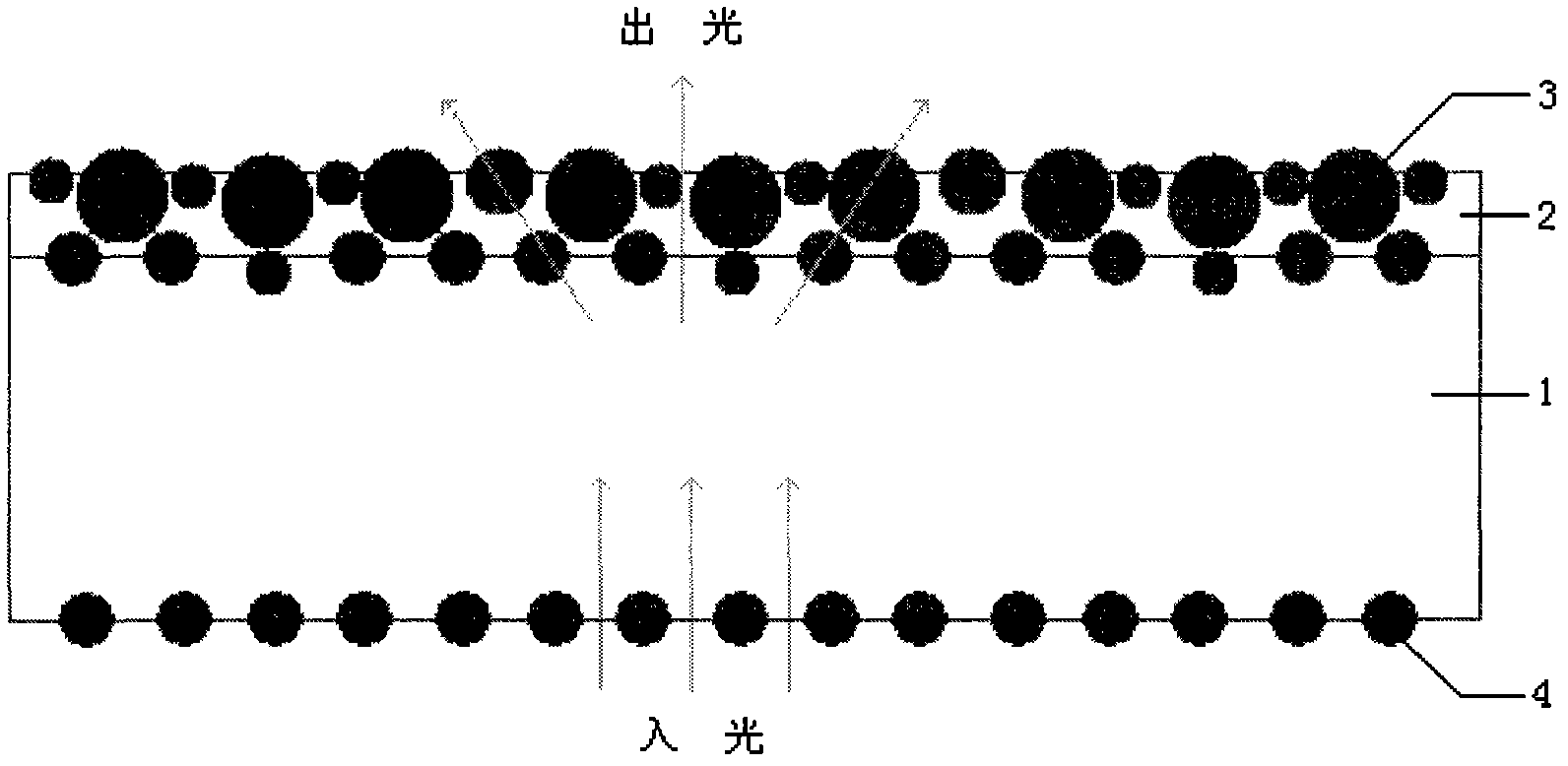

[0054] (2) Preparation of diffusion membrane

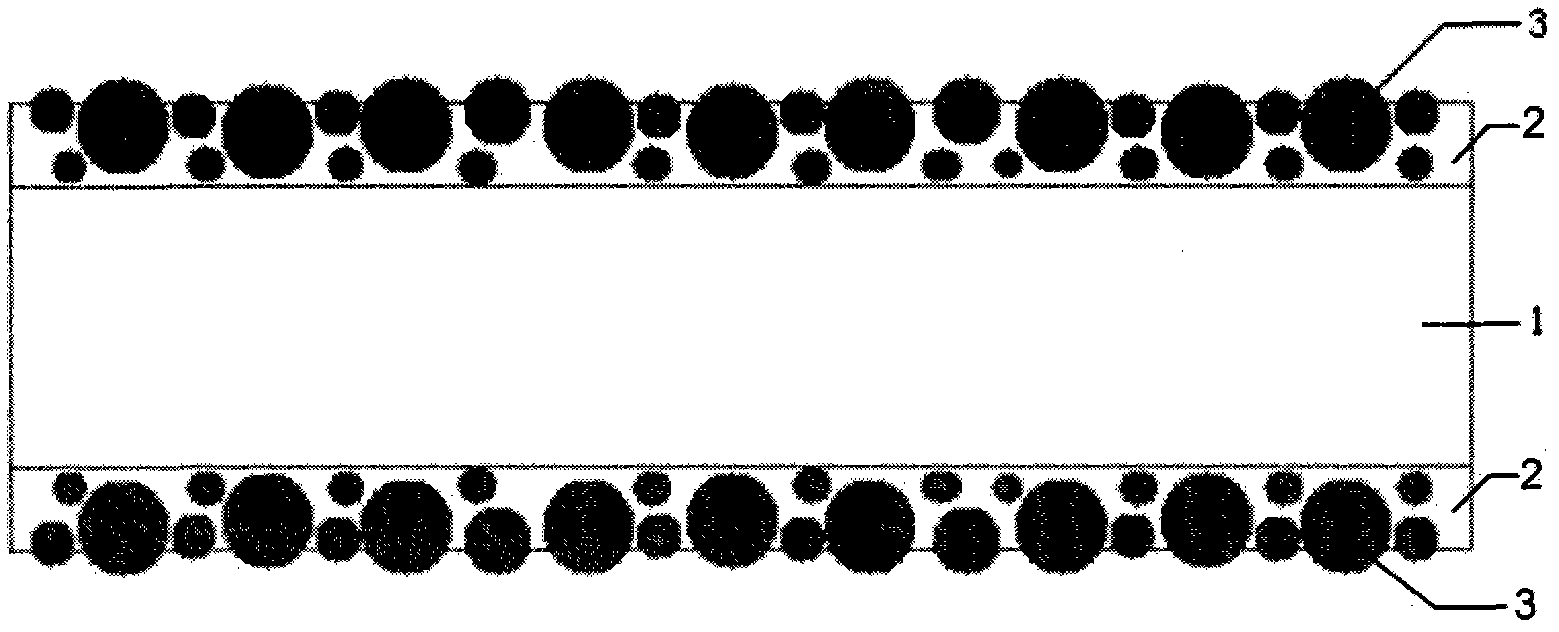

[0055] Mix the scattering masterbatch obtained in step (1) with the polyester chip, wherein the weight ratio of the scattering masterbatch and the polyester chip is 30-50:70-50 to make a mixture A, and the obtained mixture A is mixed with the substrate Raw material B is melted and plasticized separately, and the resulting melt enters the die head of the three-layer co-extruder through a distributor. The two outer layers are compound A, and the middle layer is base material B. The resulting thick s...

Embodiment 1

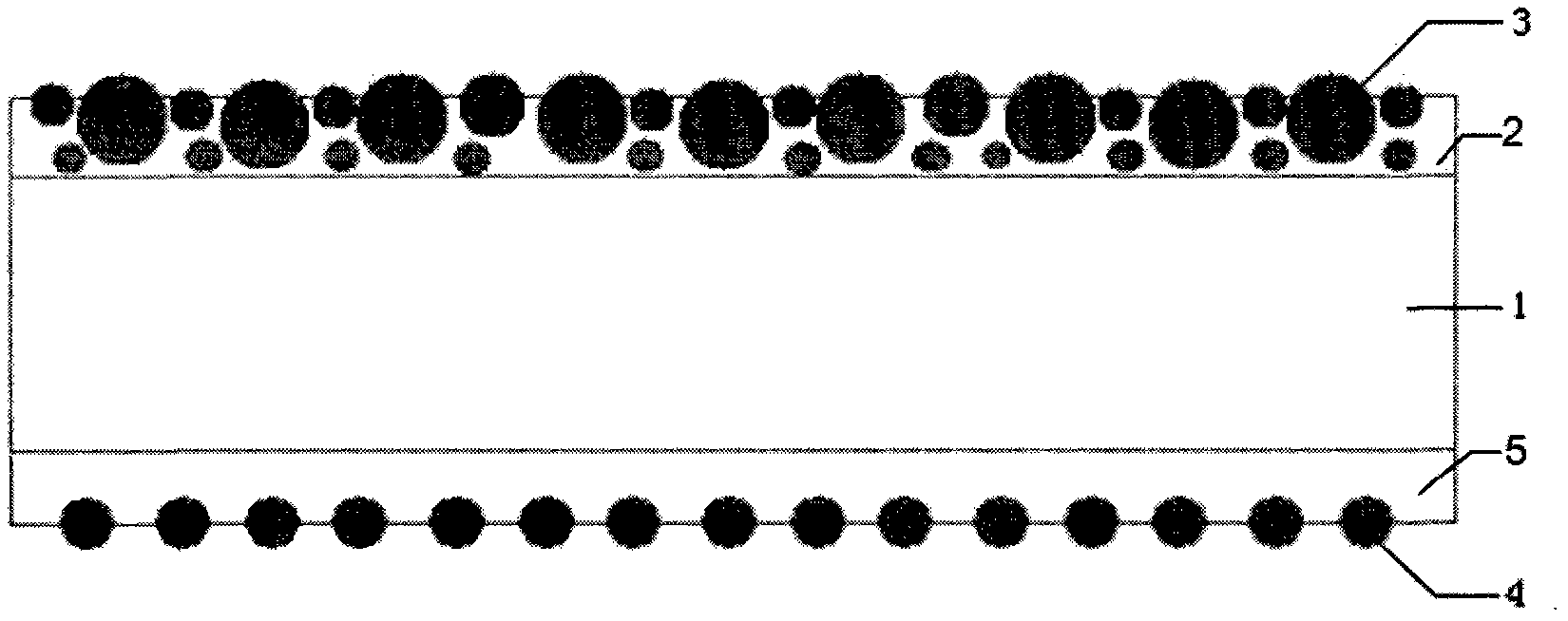

[0063] Diffusion film is prepared according to the aforementioned method, the gained film thickness is 75um, single diffusion layer, the weight ratio of scattering masterbatch and bright section in the diffusion layer is 32: 68, PMMA particle size is 2-10um, the weight in masterbatch The content is 6g / kg, the weight ratio of the anti-adhesion masterbatch to the glossy chip in the anti-blocking layer is 35:65, and the middle layer uses the glossy chip entirely. The resulting diffuser membrane is figure 2 As shown, the film surface anti-blocking performance and optical properties (light transmittance, haze) measurement results are shown in Table 1.

Embodiment 2

[0065] Prepare the diffusion film according to the aforementioned method, the obtained film thickness is 125um, single diffusion layer, the proportioning of scattering masterbatch and bright slice in the diffusion layer is 36:64, PMMA particle size is 2-20um, the weight in masterbatch The content is 6g / kg, the weight ratio of the anti-adhesion masterbatch to the glossy chip in the anti-blocking layer is 35:65, and the middle layer uses the glossy chip entirely. The resulting diffuser membrane is figure 2 As shown, the film surface anti-blocking performance and optical properties (light transmittance, haze) measurement results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com