Method for measuring time constant of rotor of asynchronous machine

A rotor time constant and asynchronous motor technology, which is applied in motor generator testing, AC motor control, electrical components, etc., can solve problems such as complex calculations and large measurement errors, and achieve the effects of accurate values, simple algorithms, and simple measurement methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further illustrate the present invention below in conjunction with accompanying drawing.

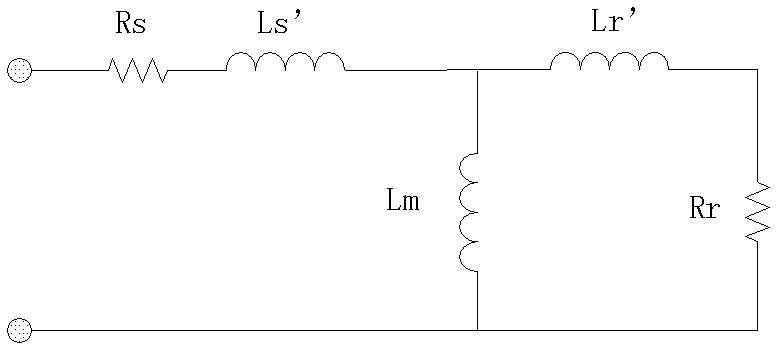

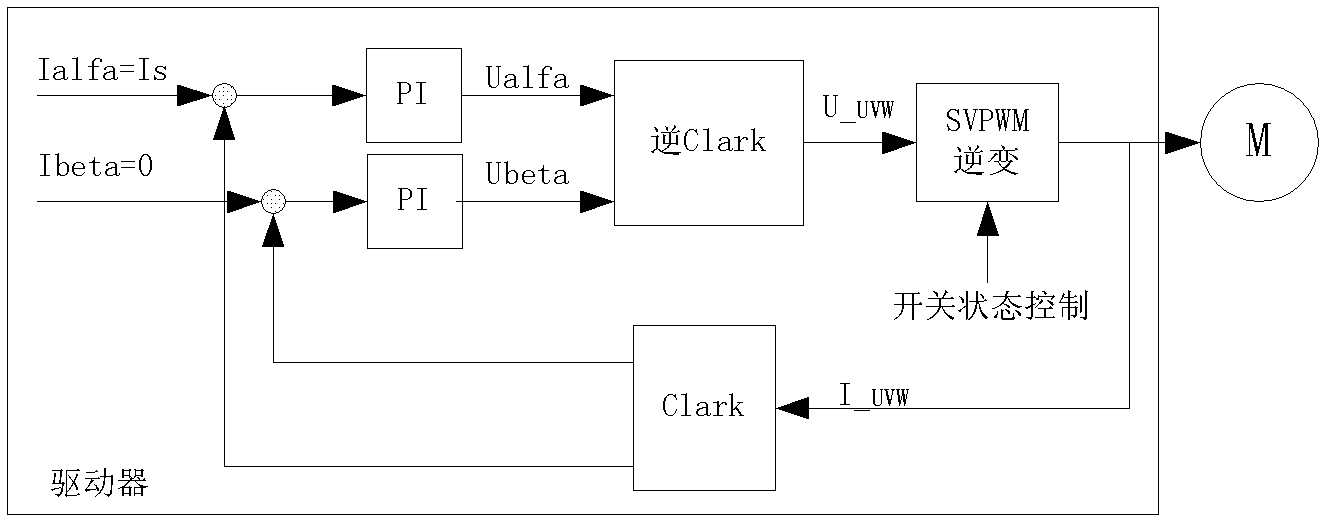

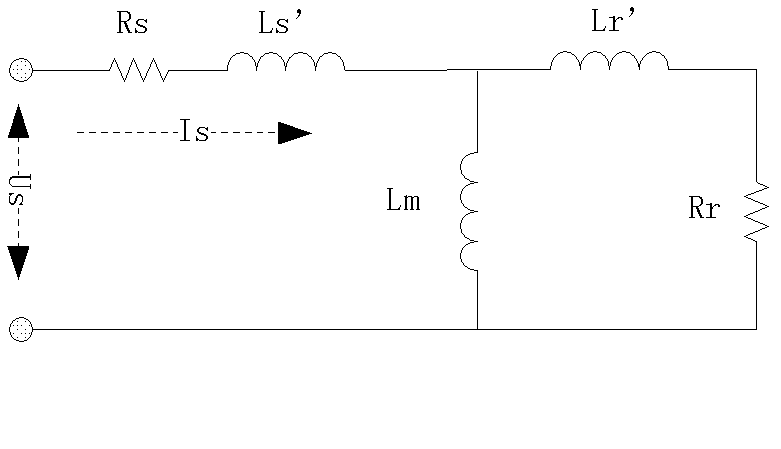

[0021] refer to Figure 1 to Figure 6 , a method for measuring the rotor time constant of an asynchronous motor. The inverter or servo drive connected to the asynchronous motor contains an inverter bridge. When the inverter bridge is in the inverter state, when the stator current and voltage are zero , given the stator current I s , the working time is t m , when the magnetizing current reaches the maximum value I m0 , record I m0 ; excitation t m After that, the inverter bridge is immediately closed, and after a period of time, the stator current is zero; after the stator is cut off, the inverter bridge is set to a three-phase short-circuit state, and the stator current I s Gradually rising from zero, I s reaches the maximum I sz , record I sz , waiting for the motor current decay excitation to be zero, the measurement method includes the following steps:

[0022] a) Giv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com