Mass production tester and mass production aging test system

A technology of aging test and tester, which is applied in the direction of measuring electrical variables, instruments, measuring electricity, etc., can solve the problems of no aging test function, low mass production efficiency, and many test procedures in the test process, so as to improve test efficiency and save manpower. Cost and effect of reducing test procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

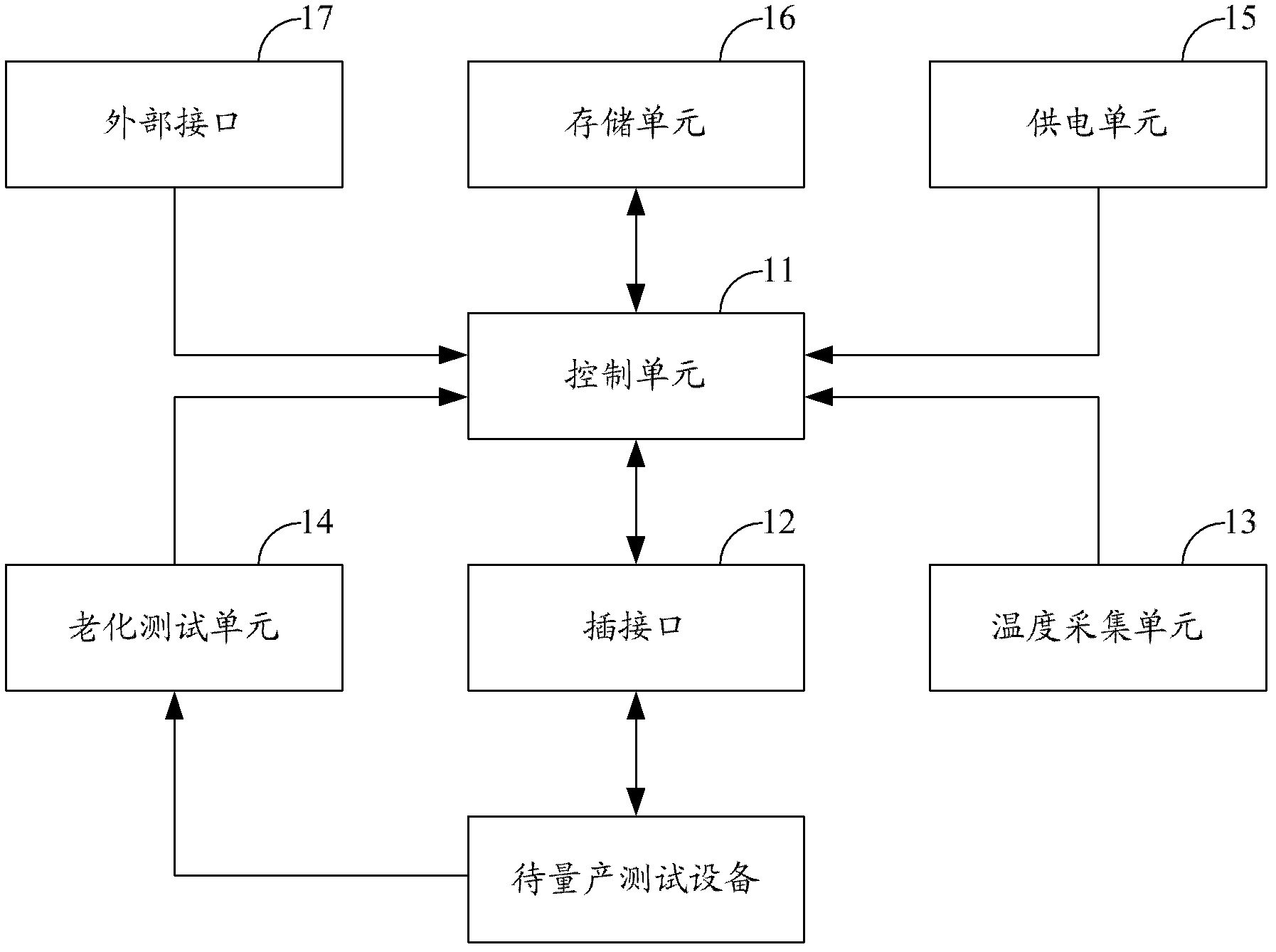

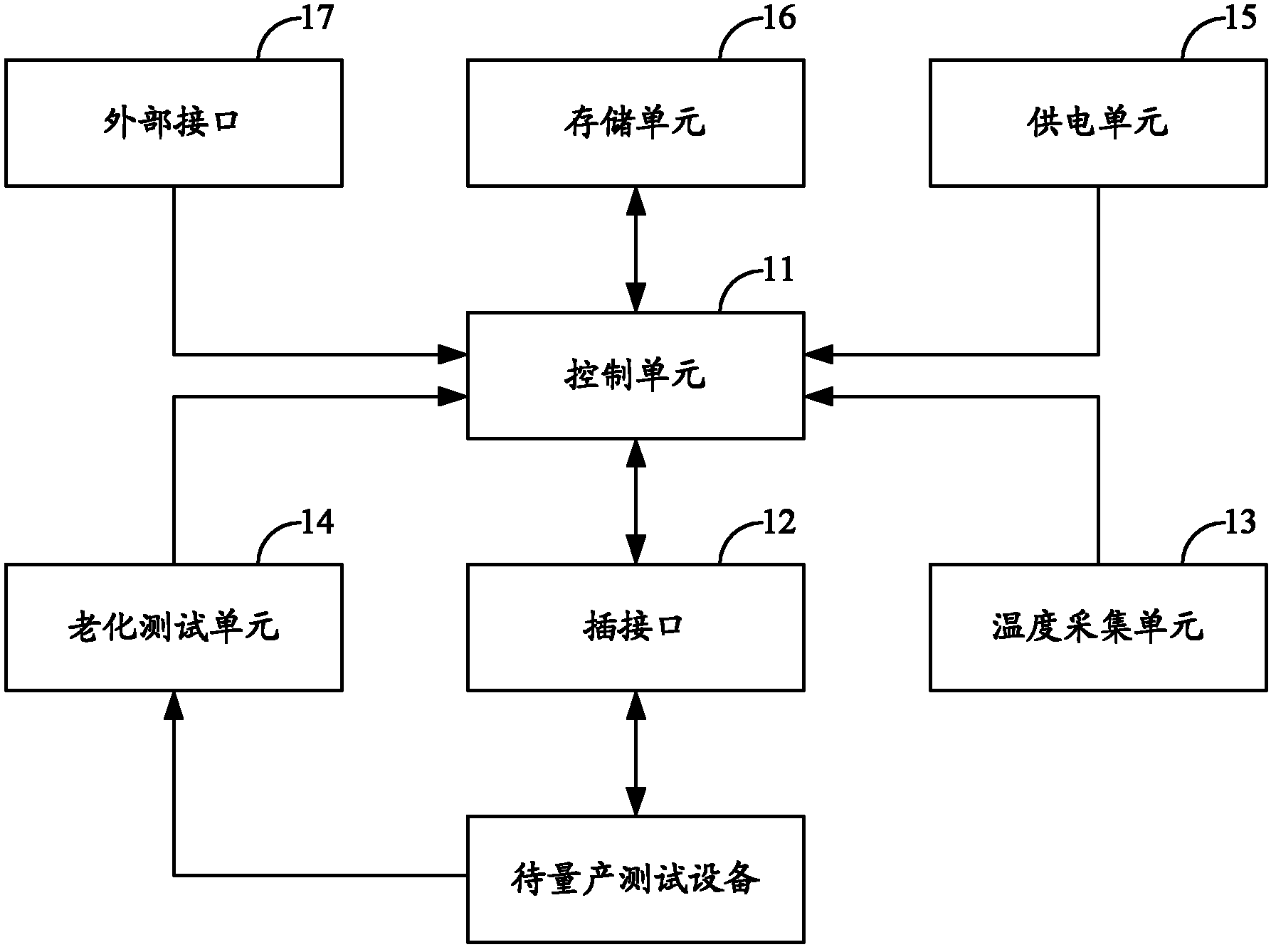

[0016] In order to overcome the disadvantages of the mass production tester provided by the prior art, the mass production tester provided by the embodiment of the present invention adds a temperature acquisition unit and an aging test unit on the existing basis, so that the mass production tester has In addition to the mass production test function, it also has the function of aging test.

[0017] figure 1 It is a functional block diagram of the mass production tester provided by the embodiment of the present invention, and for the convenience of description, only the parts related to the embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com