Detection device used for testing welding pulling force of patch type diode

A detection device and diode technology, applied in the direction of measuring devices, mechanical devices, semiconductor/solid-state device testing/measurement, etc., can solve the problem of small welding tension, achieve smooth up and down movement, effectively fix test data, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

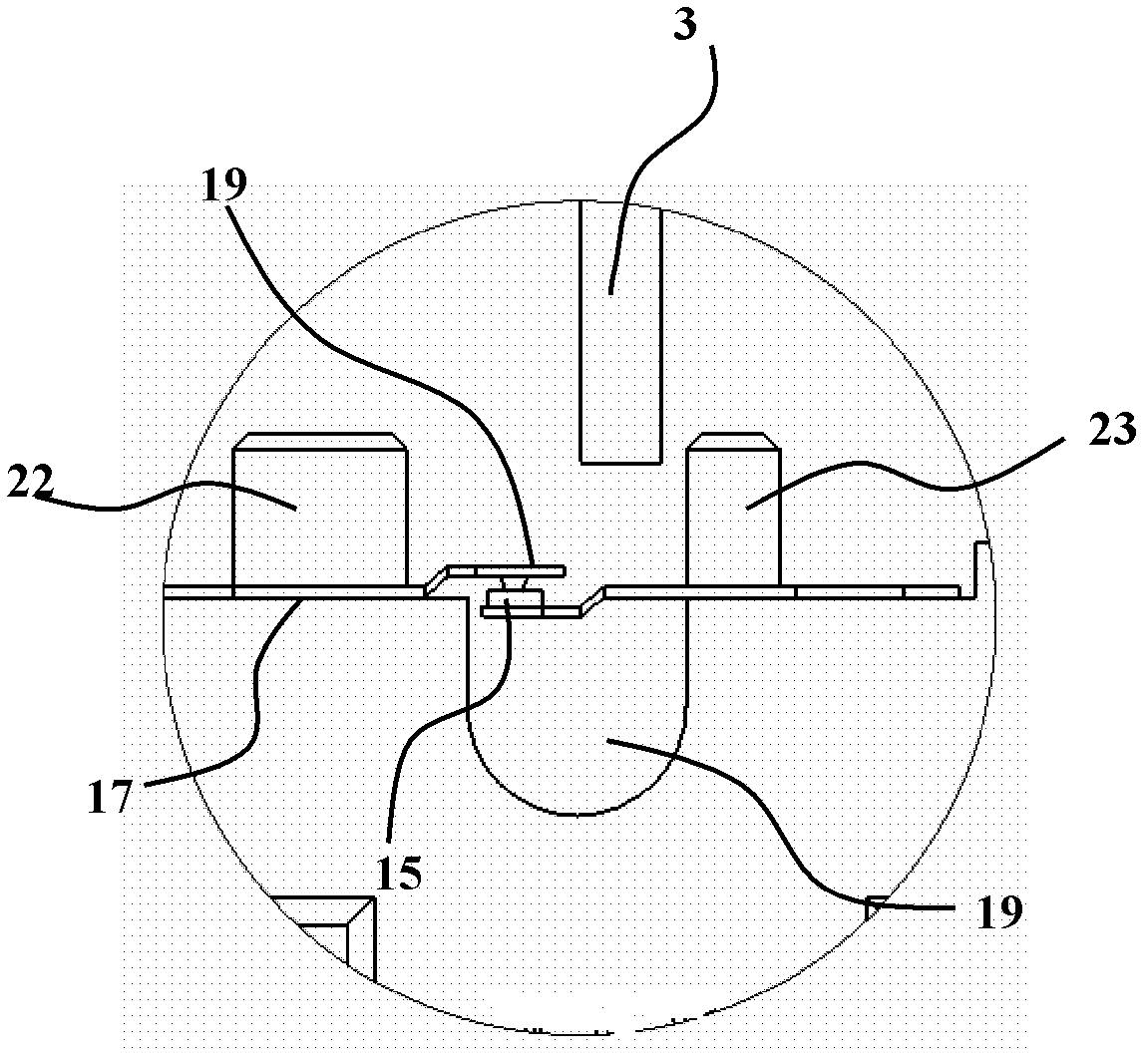

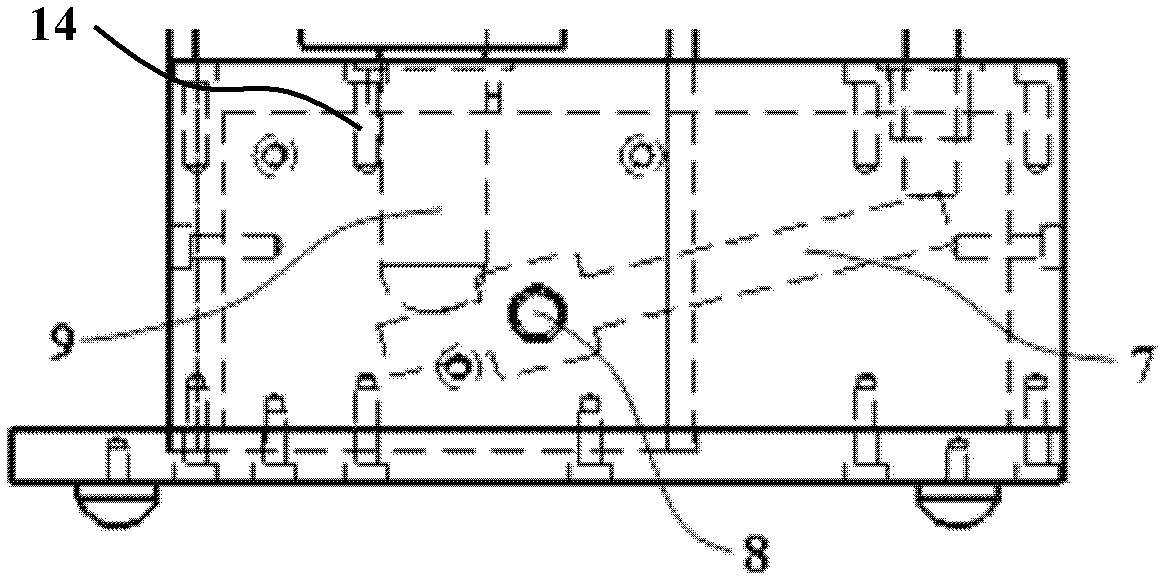

[0022] Embodiment: a kind of detection device that is used to test the soldering tension of chip type diode, the component 13 to be tested of this detection device comprises at least one chip 15, has the first lead frame 17 and the second lead frame 17 of several alternately arranged lead strips 16 respectively. Lead frame 18, one end of the pin bar 16 of the first lead frame 17 is a chip supporting area 19, and the other end is fixedly connected to the first rib 20, one end of the pin bar of the second lead frame 18 is a chip supporting area 19, and the other end is Fixedly connected to the second connecting rib 21, the chip 15 is welded between the chip support area 19 of the first lead frame 17 and the chip support area 19 of the second lead frame 18, and the detection device includes: a hollow fixed base Seat 1 and fixed plate 2 fixed on the upper surface of this fixed base 1, a push-pull force gauge 4 with a top block 3 at the lower end for testing pressure is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com