Heat exchange tube

A technology of heat exchange tubes and heat conduction tubes, which is applied in the field of heat exchange tubes and can solve the problems of easy damage, medium speed and slow speed, poor effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Describe in detail below in conjunction with accompanying drawing and embodiment:

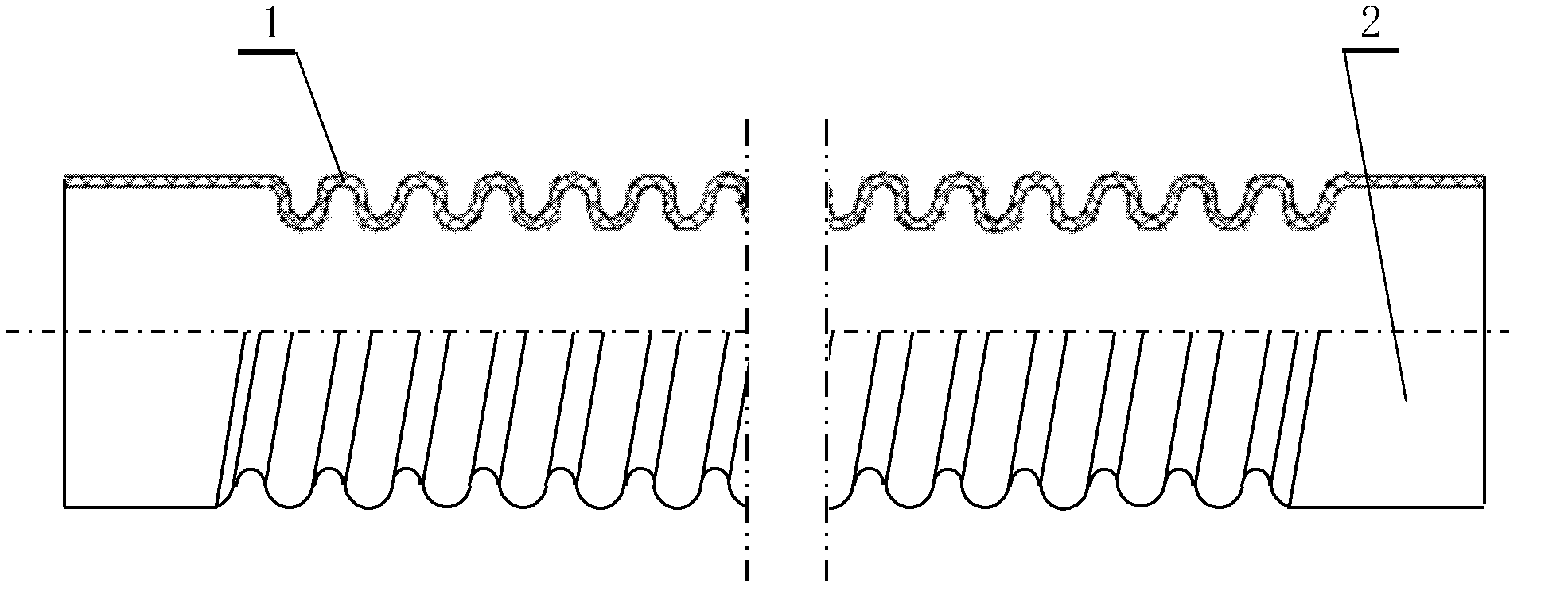

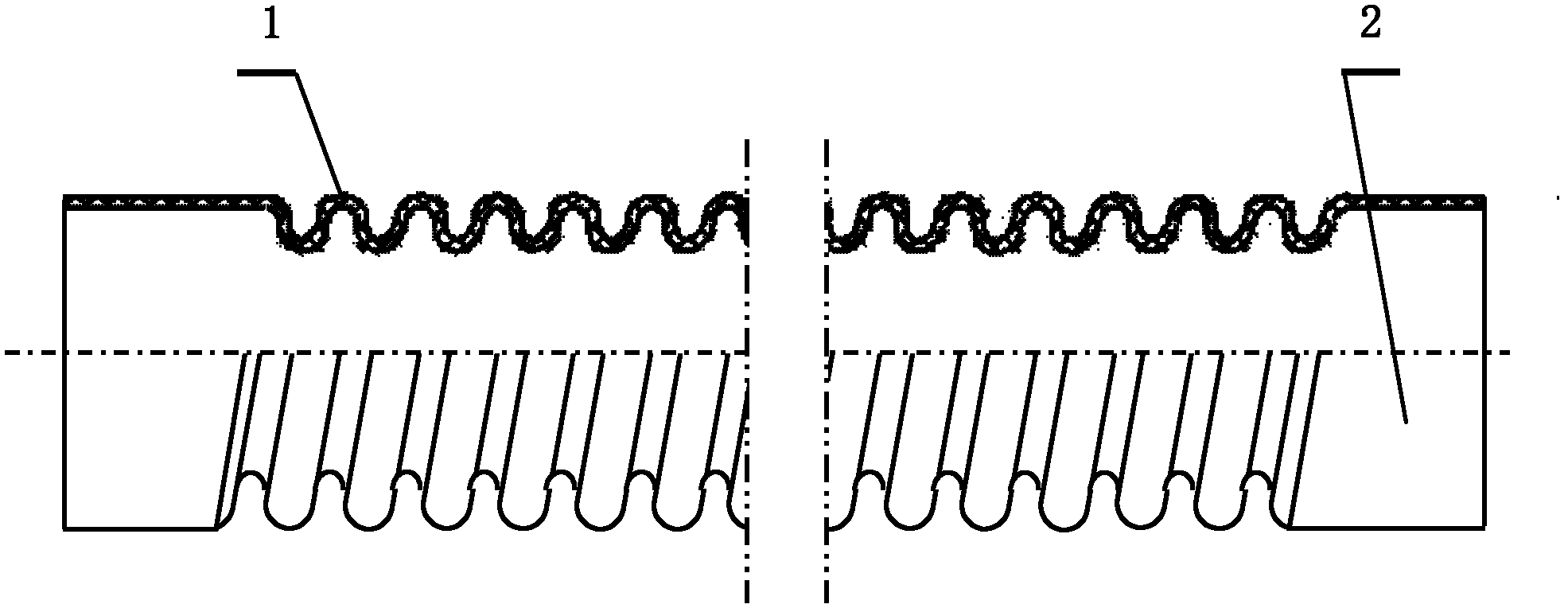

[0009] The accompanying drawing is a heat exchange tube of the present invention. It includes a heat exchange tube 1, and its main points are: the heat exchange tube 1 is a threaded corrugated tube. Apparently, the threaded corrugated pipe is a corrugated pipe whose exterior is in the shape of an external thread and whose pipe hole is a corresponding internal threaded hole. The heat exchange tube in the accompanying drawings is a graphite-modified polypropylene heat exchange tube or a graphite-modified polybutene heat exchange tube. Obviously, the heat exchange tube can also be made of other materials.

[0010] In order to facilitate the welding with the tube sheet and make the welding more firm and less likely to leak, both ends of the threaded bellows in the figure are equipped with pure PP or PB straight pipe joints 2, that is, there are two ends of the heat exchange tube 1. Pure PP ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com