Process for making nitrogen by air separation or making nitrogen and simultaneously producing oxygen in attached manner

An air separation and nitrogen technology, which is applied in cold treatment separation, refrigeration and liquefaction, liquefaction and other directions, can solve the problems of high energy consumption in the operation of the device and low extraction rate of process products, and achieve the requirements of reducing energy consumption, low energy consumption and low discharge pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Production of nitrogen 30500 Nm 3 / h

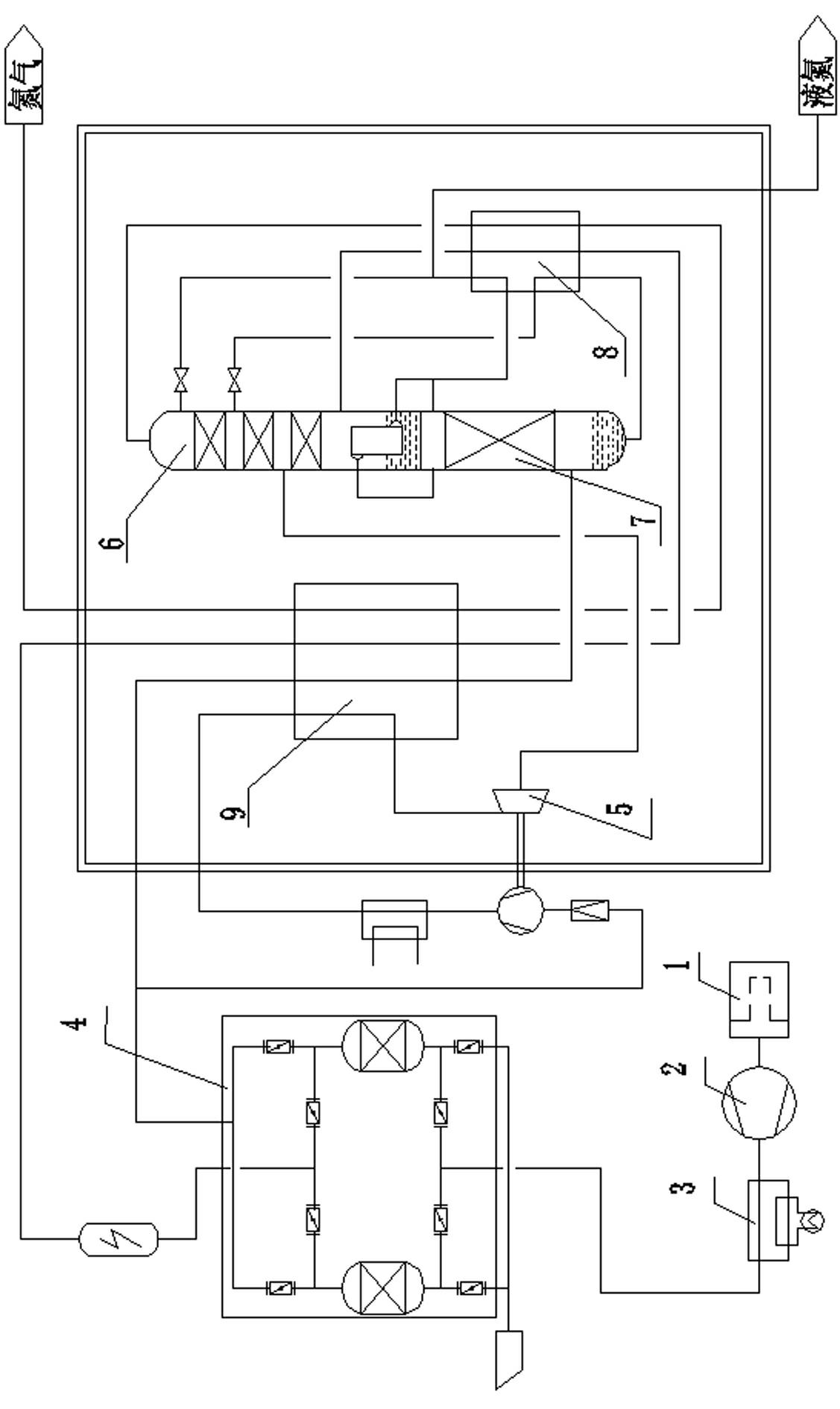

[0035] combine figure 1 , feed air 43000 Nm 3 / h The dust and impurities in the air are removed by the air filter 1, and then compressed to 0.41MPa by the air compressor 2, and then the air temperature is reduced to 5-8°C by the pre-cooling system 3, and the free water is separated before entering the purification system 4. Remove H 2 O.CO 2 、C 2 h 2 and other hydrocarbons.

[0036] The purified air is split into two paths: 9500 Nm of which 3 The air per hour enters the booster expander 5 for expansion and refrigeration. After expansion, the air enters the middle part of the upper rectification tower 6 to participate in rectification. You get nitrogen at the top and oxygen-enriched liquid air at the bottom.

[0037] The nitrogen obtained at the top of the lower rectification tower 7 enters the condensing evaporator at the bottom of the upper rectifying tower 6 as a heat source and is cooled into liquid nitrogen by the oxyg...

Embodiment 2

[0042] Nitrogen production: 25000 Nm 3 / h, liquid oxygen: 500 Nm 3 / h.

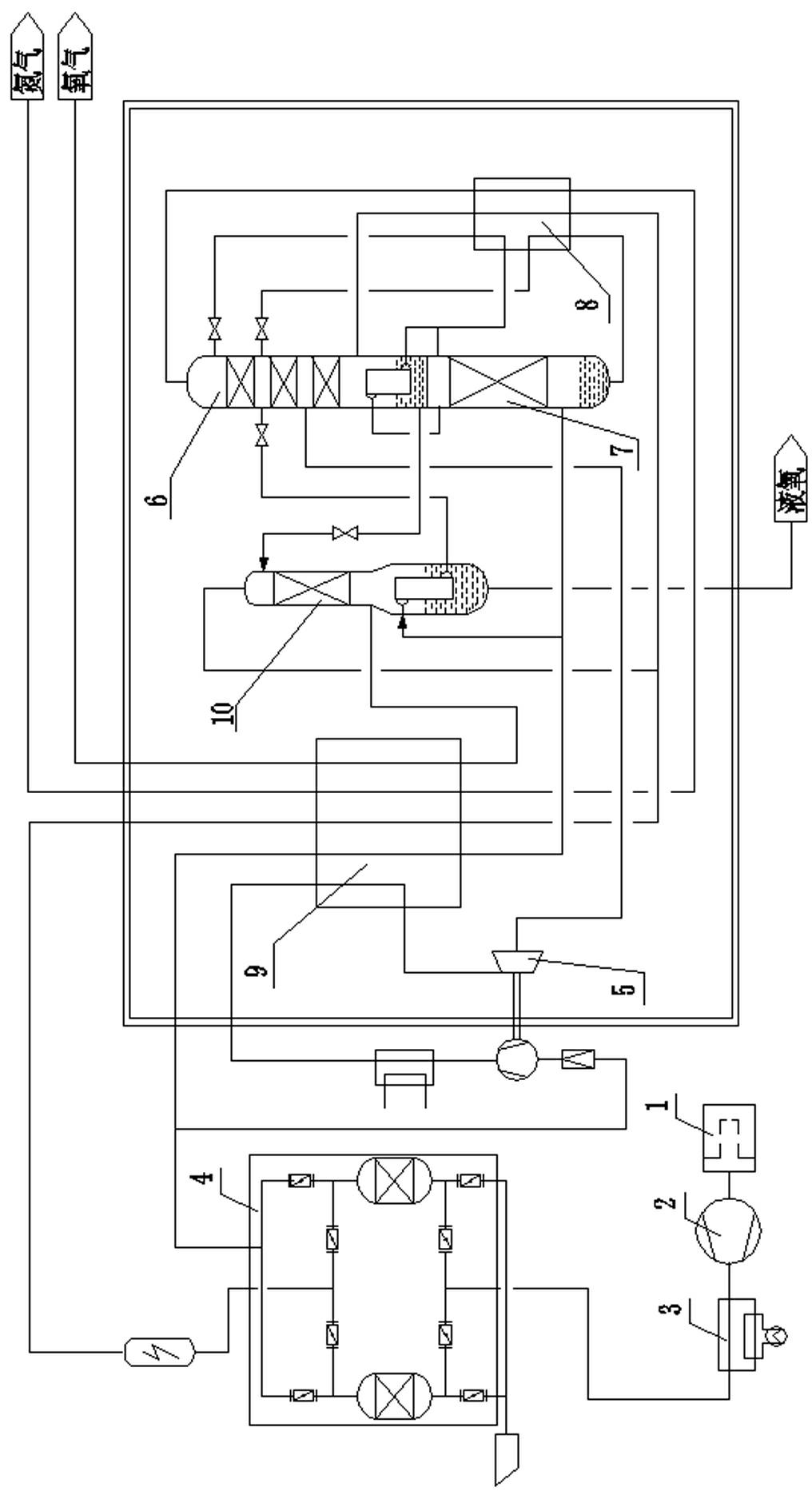

[0043] combine figure 2 , feed air 34000 Nm 3 / h The dust and impurities in the air are removed by the air filter 1, and then compressed to 0.41MPa by the air compressor 2, and then the air temperature is reduced to 5-8°C by the pre-cooling system 3, and the free water is separated before entering the purification system 4. Remove H 2 O.CO 2 、C 2 h 2 and other hydrocarbons.

[0044] The purified air is divided into two paths: 9000 Nm of which 3 The air per hour enters the expander 5 for expansion and refrigeration. After expansion, the air enters the middle part of the upper rectification tower 6 (with 60 trays of structured packing corresponding to the packing) to participate in rectification. The rest of the air is cooled to the saturation temperature and divided into two parts: 23700 Nm 3 The air per hour enters the lower rectification tower 7 as rising steam to participate in rectification, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com