Air-water double heat source three-media compound heat exchanger

A heat exchanger, three-medium technology, applied in the direction of indirect heat exchanger, heat exchanger type, space heating and ventilation, etc., can solve the problems of difficulty in popularization and use, and achieve easy sheathing, simple processing technology, and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

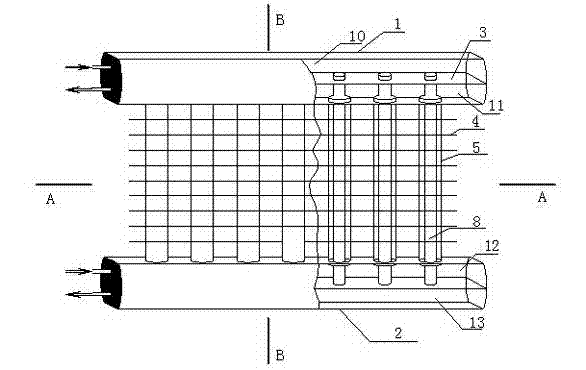

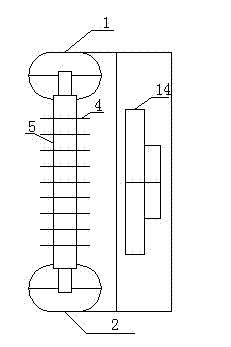

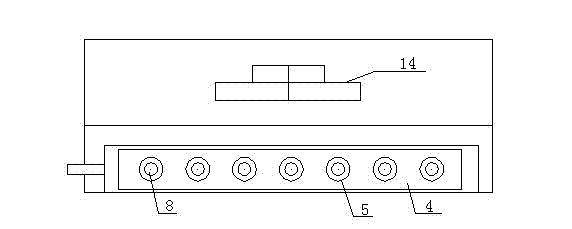

[0018] Such as figure 1 , figure 2 , image 3 As shown, the air-water dual heat source three-medium composite heat exchanger includes a fan 14 and a heat exchanger body, the heat exchanger body includes a liquid distribution pipe 1 and a liquid collection pipe 2, and the liquid separation pipe 1 is divided by 3 partitions. For the first cavity 10 and the second cavity 11, the liquid collecting pipe 2 is divided into the third cavity 12 and the fourth cavity 13 by the partition plate 3, and the first cavity 10 and the fourth cavity 13 are divided by the inner tube 8 connected, the second cavity 11 and the third cavity 12 are communicated by the outer tube 5, the outer tube 5 is sleeved outside the inner tube 8, and the outer wall of the outer tube 5 is provided with fins 4, the liquid distribution tube 1 and the liquid collection Between the tubes 2 there is at least one row of outer tubes 5 .

[0019] The liquid distribution pipe 1 and the liquid collection pipe 2 are fla...

Embodiment 2

[0023] Such as Figure 4 As shown, the fins 4 are winding fins, and other structures are the same as in Embodiment 1.

Embodiment 3

[0025] Such as Figure 5 As shown, two rows of outer tubes 5 are arranged between the liquid distribution tube 1 and the liquid collection tube 2 .

[0026] As preferred option one of the present invention, such as Image 6 As shown, the two rows of outer tubes 5 are arranged in parallel.

[0027] As the second preferred scheme of the present invention, such as Figure 7 As shown, between the two rows of outer tubes 5 is a fork row form, which is also called a dislocation form.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com