Shell water boiler

A hot water boiler and pot shell technology, which is applied in the field of pot shell hot water boilers, can solve the problems of large thermal resistance of scale, hinder the cooling of tube sheets, and cracks, so as to prevent the deposition of scale, reduce the amount of bending, and facilitate processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

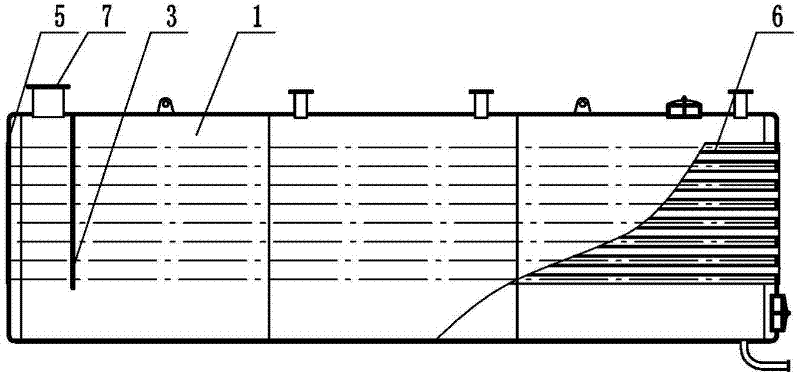

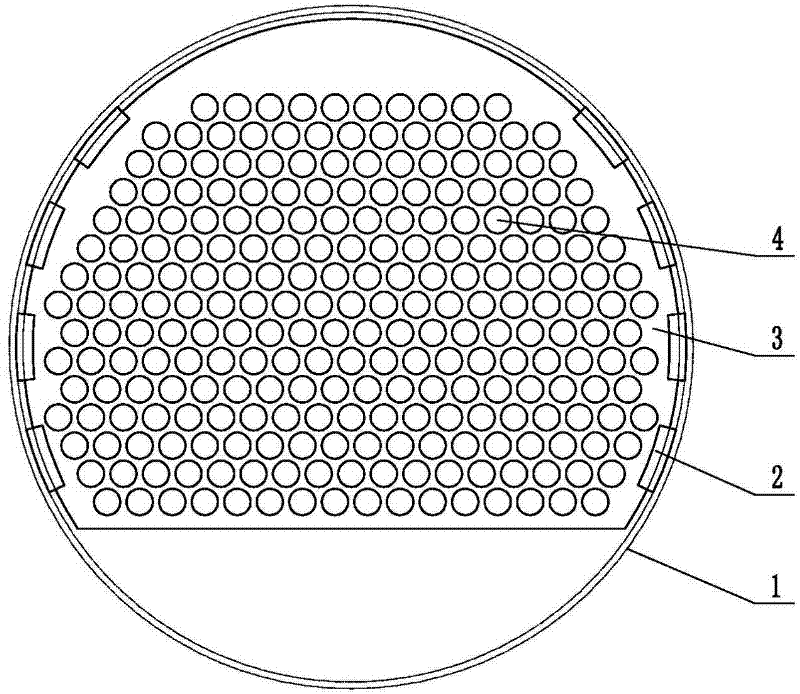

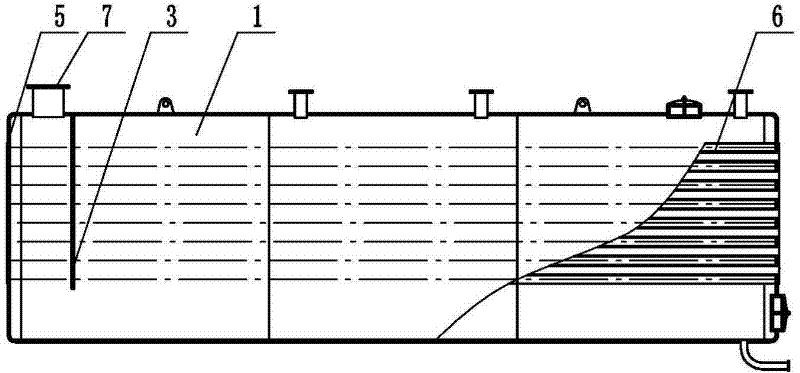

[0010] The present invention includes a cylinder body 1 of the boiler, the two ends of the cylinder body 1 are tube plates 5, the front end of the cylinder body 1 is provided with a water outlet pipe 7, the smoke pipe 6 is between the two tube plates 5, and behind the water outlet pipe 7 of the cylinder body 1 A water baffle 3 is arranged on the inner wall of the barrel, and a through hole 4 is arranged on the water baffle 3 corresponding to the smoke pipe 6 through which the smoke pipe 6 passes.

[0011] The outer edge of the water baffle 3 can be provided with a connecting arc plate 2; the water baffle 3 is connected with the inner wall of the cylinder body 1 through the connecting arc plate 2, and the installation is more convenient.

[0012] The number of connecting arc plates 2 is set to 8, which are evenly distributed on both sides of the water baffle plate 3; the force is uniform and the structure is stable.

[0013] The lower end of the water baffle 3 is set as a strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com