Extreme pressure automatic diffusing device in pipe network of gas system

A gas system and pipe network technology, applied in the direction of valves absorbing fluid energy, valve devices, engine components, etc., can solve the problem that the sealing structure is difficult to be safe and reliable, the counterclockwise torque of the valve cover increases, and the force on the plane of the valve cover Uneven problems, to achieve the effect of excellent mechanical shock resistance, stable and controllable force, and stable piston running state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

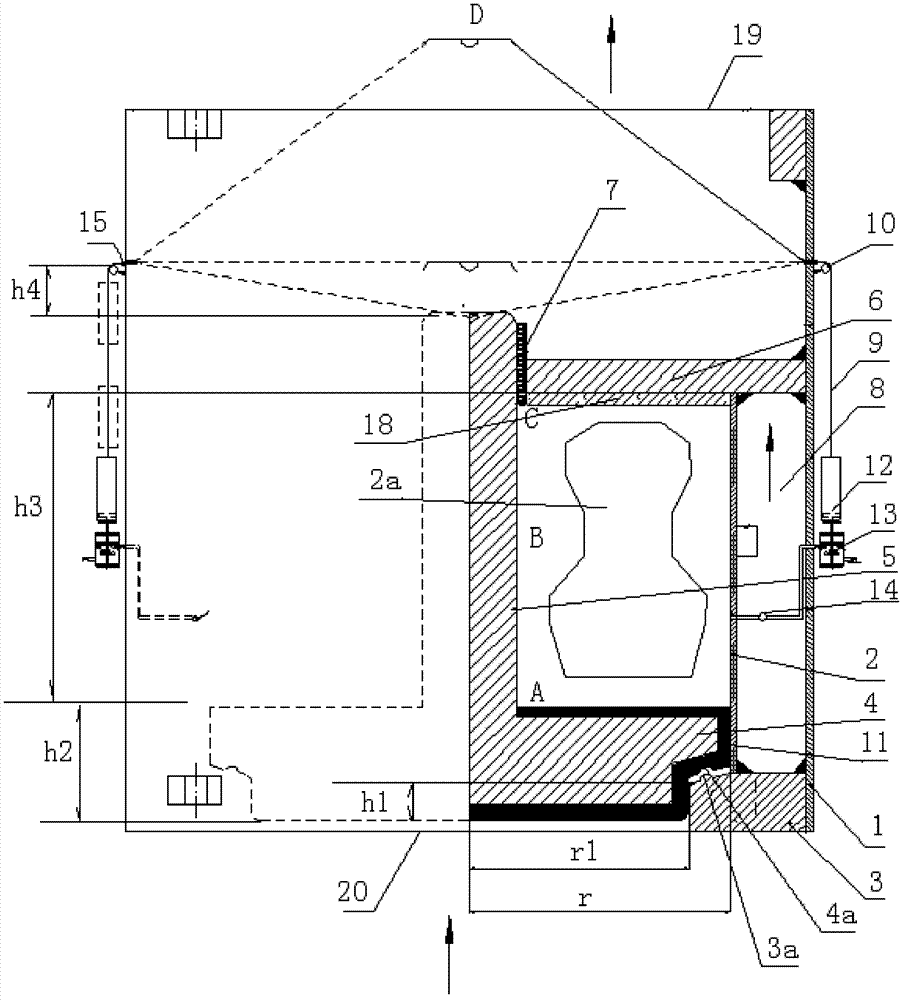

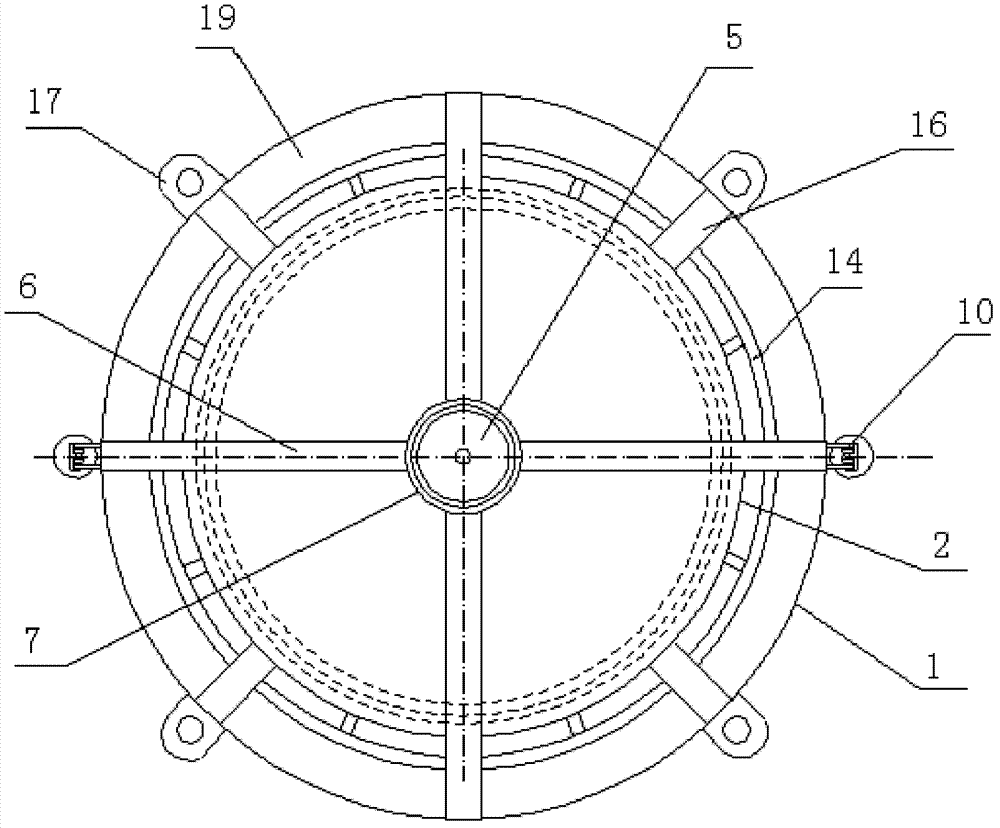

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] figure 1 , figure 2 It is a structural representation of the present invention:

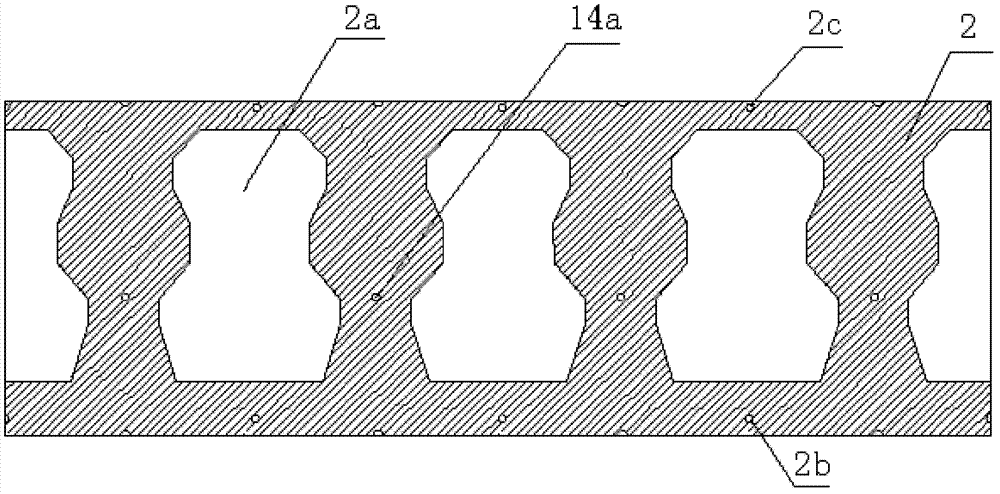

[0030] The ultra-high pressure automatic release device in the gas system pipe network of the present invention includes a cylinder body, a piston in the cylinder body, and a piston rod. The cylinder body includes an outer cylinder 1, and an inner cylinder coaxial with it is arranged in the outer cylinder 1. 2. There is a vent 2a on the inner cylinder 2 to communicate with the inner cylinder 2 and the outer cylinder 1, and the middle annular area 8 of the outer cylinder 1 and the inner cylinder 2 communicates with the upper exhaust port 19 of the outer cylinder 1; the lower port of the outer cylinder 1 is connected to the annular base 3. The upper end face is connected, and the lower port of the inner cylinder 2 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com